Sensory interactive fibers and textiles

Introduction

Textile apparel is considered a second skin for people, primarily offering essential protection functions1. Additionally, textile garments reflect personal aesthetic preferences. In the recent decade, they have been given new functions as intelligent textiles. Intelligent textiles contain electronic fibers in various textile structures for transmission and detection, housing intelligence functions such as sensing, actuation, and communication. Especially, intelligent interactive e-textiles convert stimuli from the environment (temperature, light, chemicals, moisture, pH) or interactions (mechanical force and electromagnetic field) into responses in aesthetic (color, light intensity, fluorescence, shape or form) or physical (mechanical, electrical, thermal, chemical, wetting or moisture transport) properties2. These textiles engage almost all human senses, such as visual, haptic, auditory, or olfactory. Hence, sensory interactive e-textiles are indispensable in human-machine interaction due to their unique dynamic change characteristics, providing a more intelligent and personalized wearing experience. Sensory interactive e-textiles have great potential in diversified fields, including personal protection3, sports4, healthcare5, military6, and fashion7. Despite their significant advancements, developing and applying sensory interactive e-textiles exhibit considerable growth potential. More importantly, how to create sensory interactive e-textiles that meet user needs and achieve the best interactive performance is still an area to be explored.

Compared to traditional materials, the uniqueness of sensory interactive e-textiles is highly multidisciplinary and collaborative. Developing and incorporating sensory interactive e-textiles need contributions from seemingly unrelated fields, such as material scientists, computer scientists, artists, and designers8. They are united in exploring concepts for intelligent e-textiles yet separated in their approach. On the one hand, scientists discover new materials and characterize their properties, while engineers apply a material’s properties and functionalities to solve problems. On the other hand, designers and artists move materials out of the science lab and into practical applications9. These collaborations, while enabling the innovation of sensory interactive e-textiles, also present challenges to address gaps brought at every step, from manufacturing each component to the end-use application.

This review defines the three typical development generations of intelligent e-textiles. Firstly, the sensory interactive e-textiles based on different senses have been summarized better to understand the intelligent interaction between humans and textiles. Then, detailed insights into how flexible electronics have been or can be incorporated into e-textile systems. Meanwhile, considering the characteristics of multidisciplinary cooperation, we propose a new design paradigm based on analyzing the inadequacy of the existing intelligent e-textile design process. Lastly, the development trend and potential problems of sensory interactive e-textiles are highlighted. Thus, this review aims to help scientists and designers collaborate more effectively in developing sensory interactive e-textiles in the context of interdisciplinary work. At the same time, envision the potential contribution of innovative interactive e-textile technologies for revolutionizing human-machine interaction interface in the information society, aiming to catalyze further iterative progress in the field of next-generation sensory interactive e-textiles.

The history of interactive e-textiles

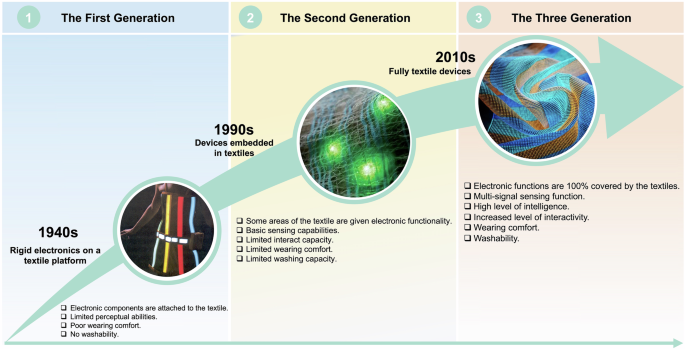

Interactive e-textiles have evolved significantly, progressing through three generations: (1) rigid electronics on a textile platform, (2) devices embedded in textiles, and (3) fully textile devices. The three generations’ development of interactive e-textiles is shown in Fig.1. The foundational advances in electronics, catalyzed by the invention of the transistor in the late 1940s, facilitated the integration of electronic components into textiles. In 1968, Designer Diana Dew10 created a wearable Pop Art piece, “Movie Dress”, a luminescent textile that laminated thin phosphor lights onto the leather. Movie Dress brings a new way of wearing and entertaining people. The first generation of e-textiles pushed the boundaries of textile craftsmanship and engineering by constantly experimenting with embedded electronics. Therefore, they were also called “smart textiles-adapted”, which means that the textiles do not encompass electronic functions and electronic components are combined with textiles in the form of attachments. These early e-textiles were cumbersome and lacked the aesthetics, textural comfort, bending, and drapability typical of textiles.

A three-generation development of interactive e-textiles.

In the 1990s, the second generation of interactive e-textiles emerged, marked by the development of components such as textile antennas11, semiconductors12, electrodes13 and sensors14. Textile technology and new integration techniques such as weaving, knitting, surface coating, electroplating, embroidery, printing, and lamination were applied to functional materials15. Therefore, the second generation of e-textiles is called “smart textiles-integrated”. This category of textiles covers some electronic functions, utilizing new integration techniques to establish interrelationships between electronic components and textiles. Conductive and semiconductive materials such as fibers, inks, films, and gels combine with traditional yarns or fabrics to create specific structures and patterns that generate electrical, mechanical, magnetic, and optical properties. Second generation e-textiles, developed from functional yarns using integration techniques, effectively address challenges related to comfort, flexibility, tactile properties, and washability16. These e-textiles have been applied in fashion aesthetics, biometric monitoring and therapeutic interventions17. However, second generation e-textiles can usually only be used to solve a single or limited problem, and their interaction with the human body is restricted. Therefore, third generation e-textiles with integrated multi-functionality have been developed.

The third generation of e-textiles involves embedding microelectronic devices directly into the fibers. Since the early 21st century, microconductors, semiconductors, and insulators have been embedded in individual fibers. They can utilize complex computing power to provide intelligent functions such as visual and auditory processing, sensing, and communication18. Stylios et al.19. have engineered an innovative electrochromic composite yarn. The composite yarn consists of a core thread and an outer sheath, which are thermochromic materials that change color at a given temperature. When an electric current travels through the yarn’s core, it generates heat, triggering the outer sheath’s color transition and affecting visual change. The functionality of third generation e-textiles tends more towards improvements at the fiber level, enabling fibers to carry electronic functions. Hence, these textiles are termed “smart textiles-based”, encompassing electronic capabilities. Textile-based innovative technologies represent a significant advancement in textile functionality. Ideal innovative fabrics directly incorporate electronic components and connections into the textile structure so that the electronic systems can be freed from rigidity and encapsulation and can be closely in our daily lives. This approach allows to offer discreet and comfortable wearable options. Furthermore, third generation e-textiles possess advanced capabilities, including multidimensional computing power, which are crucial for developing soft interfaces for Artificial Intelligence, Internet of Things, and 5 G wireless technologies20.

Currently, the third generation of e-textiles utilizes advanced functional materials, sensing technology, and embedded systems to integrate electronic components with textiles. These textiles can detect changes in the environment, user actions or physical conditions and respond accordingly to enhance the user experience through increased intelligence, personalization and comfort. Therefore, the third generation of e-textiles is also called intelligent interactive e-textiles. E-textiles are important in human-machine interaction, which offer substantial potential for creating innovative and natural interfaces for non-invasive intelligent living applications. This advancement helps narrow the connectivity gap between humans and machines, facilitating a more intuitive human-machine interface. The technology seamlessly integrates into flexible fabrics, enhancing the user experience and usability, enabling more effective interaction during everyday activities.

The typical representative of sensory interactive e-textiles

Under the current trend of technological development, the integration of flexible electronics based on textile substrates have inspired extensive attention and in-depth exploration in the field of academic research due to their extraordinary potential in the field of wearable technology, especially their unique value in driving smart garments to achieve a high degree of interactivity. By integrating electronic functions into traditional textiles, e-textiles not only broaden the application boundaries of bright clothing but also provide new possibilities for intelligent interaction between clothing, individuals, and the environment, signifying that innovative textile technology is moving towards a more humane and integrated advanced stage.

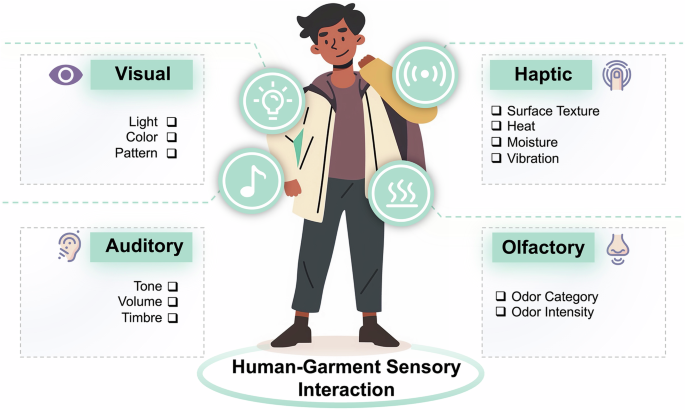

Intelligent interactive e-textile, as a product of the profound fusion of textile technology and information technology, integrates various types of textile-based materials to build an interactive system. Fiber and textile-based functional materials give e-textiles unique interactive characteristics and functional properties. By dynamically adjusting the physical state of the fabric, such as morphology change, color transformation, temperature regulation, or vibration generation, these functional materials greatly enhance the fabric’s functionality and significantly improve the user’s interactive experience. Sensory interaction is crucial for enhancing the interactive experience between humans and clothing, as shown in Fig. 2. We have categorized the e-textile according to different sensory interaction modes. The approach not only gains a deeper understanding of how various materials affect the sensory experience but also guides us to design more highly interactive e-textiles, which can further enhance the user experience.

Sensory Interaction in Human-Clothing Interaction.

The visual interaction e-textiles

Vision plays a vital role in all senses and is the most active sensory channel for transmitting information (~83%) in human-machine interaction. People can create colorful patterns to express their emotions through simple but imaginative combinations of color and light. In recent years, the rapid development of flexible electronic materials has led to the emergence of highly flexible and dynamically transformable smart textiles as a new interaction interface. As a result, adaptable, intelligent, luminescent, and chromatic materials have become a topic of considerable interest and have been widely studied. According to the different mechanisms, illuminated devices can be divided into photoluminescent, electroluminescent, and mechanoluminescent. Similarly, chromatic devices can be divided into electrochromic, thermochromic, and photochromic colored devices. This section will introduce the latest research on fiber-shaped illuminated and chromatic materials.

Luminescent

Luminescence has fascinated humans since immemorial, thanks to natural phenomena such as aurora borealis, lightning, and luminous animals21. Depending on the source of excitation, for example, electromagnetic radiation, stress (mechanical force), electric current, temperature, or magnetic field, different types of luminescence can be observed, such as photoluminescence (PL)22, mechanoluminescence (ML)23, electroluminescence (EL)24, thermoluminescence (TL)25, and magnetic-induced luminescence (MIL)26, respectively. Light, electricity, and mechanics—affording PL, EL, and ML, respectively—are by far the most utilized, and this part is specifically dedicated to these three fibers.

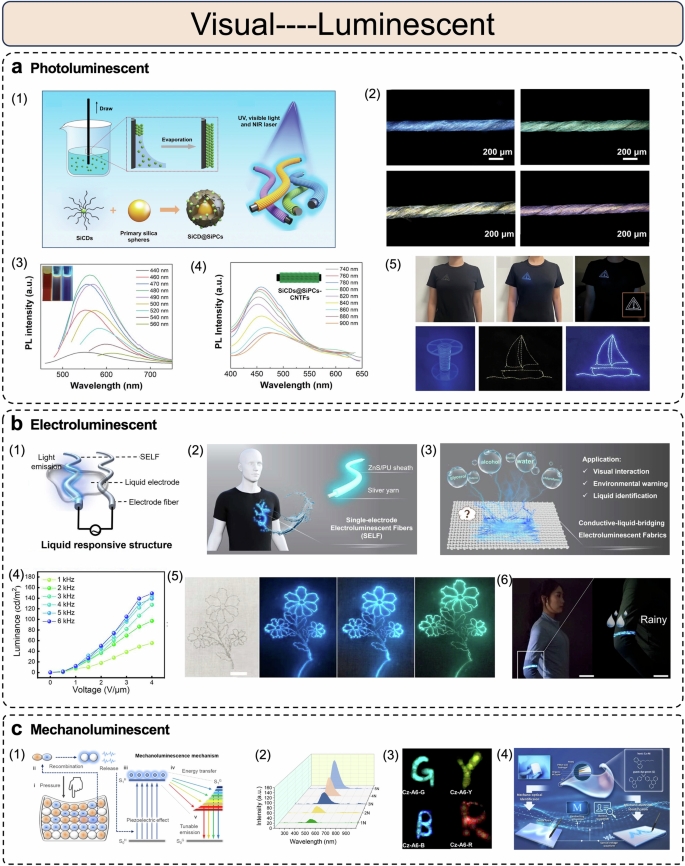

Photoluminescence (PL) is the emission of radiation induced by the optical excitation of a sample using an external light source. Existing photoluminescent materials include organic fluorophores, quantum dots, perovskites, polymer dots, lanthanide-doped nanoparticles, and so forth27. Over the past years, photoluminescent materials have attracted great attention in the textile industry due to intriguing applications in anticounterfeiting, optical sensors, smart haute couture, and wearable electronic devices28,29. Generally, luminescent fibers can be fabricated by spinning polymer matrices with fluorescent materials incorporated or coating fluorescent materials onto the surface of fibers. Presently, several protocols have been used for fabricating fluorescent fibers, including in situ growth30, dry-wet spinning method, co-electrospinning and multistep dip-coating31. Due to their flexibility and bendability, the luminescent fibers can be integrated with conventional yarns using various textile fabrication techniques, such as weaving and knitting, to create luminescent fabrics. Bai et al.32 developed an artificial intelligence fiber-optic fabric that integrates computer vision and deep learning. This fabric can change light and color modes in response to non-contact body postures, facilitating user interactive behaviors. To improve the practicability and interactivity of photoluminescent fibers, Li et al.33. introduced silane-functionalized carbon dots (SiCDs) into silica PCs and achieved structural coloring and PL of CNT fibers (CNTFs), as shown in Fig. 3a. The structural coloration and up/down conversion PL of CNTFs were realized by coating CNTFs with SiCDs@SiPCs. The structural color was generated by silica PCs coated on the surfaces of CNTFs through a simple self-assembly method. The fabrication of SiCDs@SiPCs-CNTFs not only realizes the coloration of CNTFs but also exhibits new PL properties, which play important roles in visual interactive e-textiles, flexible devices, and so on.

a Photoluminescence fiber33. (1) Schematic illustration of the preparation of SiCDs@SiPCs-CNTFs. (2) Different structural colors’ optical images. (3) The PL emission spectra of SiCDs solution with 100% loading fraction excited from 440 to 560 nm. (4) The two-photon emission spectra of SiCDs@SiPCs-CNTFs excited from 740 to 900 nm NIR femtosecond laser. (5) A T-shirt embroidered with SiCDs@SiPCs-CNTFs in different environments. Copyright©2024, Wiley‐VCH GmbH. b Electroluminescent fiber40. (1) Liquid response structure based on EL single yarns. (2) Schematic diagram of the structure of the SELFs. (3) Schematic illustration of the conductive-liquid-bridging EL fabrics based on SELFs. (4) The dependence of luminescence (for different applied frequencies) on applied voltage. (5) EL single-yarns embroidered into “flower” for water detection. (6) The sportswear glows in response to simulated rain. Copyright©2023, ACS. c Mechanoluminescent fiber47. (1) Proposed mechanoluminescent mechanism of Cz-A6 based on the piezoelectric effect. (2) ML spectra under different applied forces with a 0.3 mm-thick crystal layer. (3) Visualization of dynamic handwriting recognitions for G, Y, B, and R. (4) Visual interactive tactile display (ITD) for dual-mode identification. Copyright©2024, The Authors.

According to the different light-emitting materials and principles, the electroluminescence (EL) fibers can be broadly divided into organic light-emitting diodes (OLEDs), polymer light-emitting diodes (PLEDs), polymer luminescent electrochemical cells (PLECs), and alternating current electroluminescence (ACEL) systems and so on34. One approach to flexibilization is to incorporate stiff light-emitting diode (LED) directly-based light-emitting (LE) devices into flexible fibers and textiles35,36. In these systems, tiny LE elements are embedded within the fiber or attached to the surface of the fiber/fabric to inherit the intrinsic flexibility of the fiber. Another method is to sequentially deposit the functional layers of the two-dimensional (2D) planar LE device onto the fiber substrate, obtaining LE fibers with a coaxial structure37. This method provides excellent mechanical flexibility and high luminous efficiency. Additionally, Stretchable electroluminescent (EL) devices have recently received increasing attention as input and/or output interfaces for next-generation human-friendly visual electronic systems. Choi et al.38 present recent advances in materials and design strategies for stretchable EL devices. They mainly discussed two representative strategies to realize stretchable EL devices: “structural approach by using stretchable device designs” and “material approach by using intrinsically stretchable electronic/optoelectronic materials for device fabrication”. There have been a large amount of research efforts to advance stretchable EL fibers in response to the growing need for high-performance visual interaction. Chun et al.39 developed a novel class of EL phosphors consisting of PeNPs coated with ZnS (PeZS), which electrically excites the PeNPs through total intra-particle energy transfer. The EL spectra of PeACEL devices can be tuned from blue to deep red, with a brightness comparable to that of commercial planar displays. Li et al.40 proposed a liquid-responsive structure based on alternating-current electroluminescent fibers. They demonstrated conductive-liquid-bridging electroluminescent fabrics with high integration and personalized patterns, as shown in Fig. 3b. The EL fibers and textiles are responsive and robust and have excellent luminescent properties for water detection, visual interaction, and environmental warning. The textile-type visualizing–responding strategy proposed in this work may open new avenues for applying ACEL devices in visual interaction.

Mechanoluminescence (ML) refers to the luminescence phenomenon produced when a material is subjected to mechanical stresses, such as friction, extrusion, collision, crushing, and ultrasound41. According to the deformation process of objects, ML is divided into deformation mechanoluminescence (DML) and triboluminescence mechanoluminescence (TML). DML is the physical process caused during the deformation of solids, while TML is the contact phenomenon caused during the contact or separation of two different materials in contact42. Among them, there is a correspondence between mechanical and optical signals in mechanoluminescent materials, and the optical signals can show obvious changes with the change of mechanical information, which is promising for the development of next generation human-computer interaction media. Compared to the widely explored flexible electroluminescent devices43,44,45,46, mechanoluminescent fibers are much simpler in structure designs and do not require any electrical components. As a result, these ML fibers offer better wearing comfort and lightness, which emit reproducible light upon deformation and can fully utilize the kinetic energy generated during our movements, making them particularly suitable for interaction. To improve the applicability of ML fibers, Hou et al.47 proposed a novel ITD by integrating organic AIE-ML materials (Cz-A6-dye) with the triboelectric nanogenerator (TENG), which can simultaneously convert touch stimulus into real-time visible light and electrical signals in a self-powered way, as shown in Fig. 3c. The proposed optical and electrical dual-mode tactile display represents a significant advancement in organic ML materials, exhibiting ultra-brightness and sensitivity. This development is poised to revolutionize the landscape of next-generation interactive media.

Chromatic

Color is another core element of human visual interaction. Chromatic fibers break the traditional characteristics of complex and independent interaction interfaces as a means of interactive visualization in the intelligent textile field. They are expected to become an emerging sensory interaction interface due to their excellent wearability and natural interactivity. Chromatic fibers can produce a dynamic change in color through various mechanisms. These mechanisms enable the fibers to sense changes in external environmental factors, including light, temperature, mechanical forces, and electrical signals48. The most prevalent methods of color change are currently electrochromic, thermochromic, and photochromic fibers. This section will present the latest research findings on chromatic fibers.

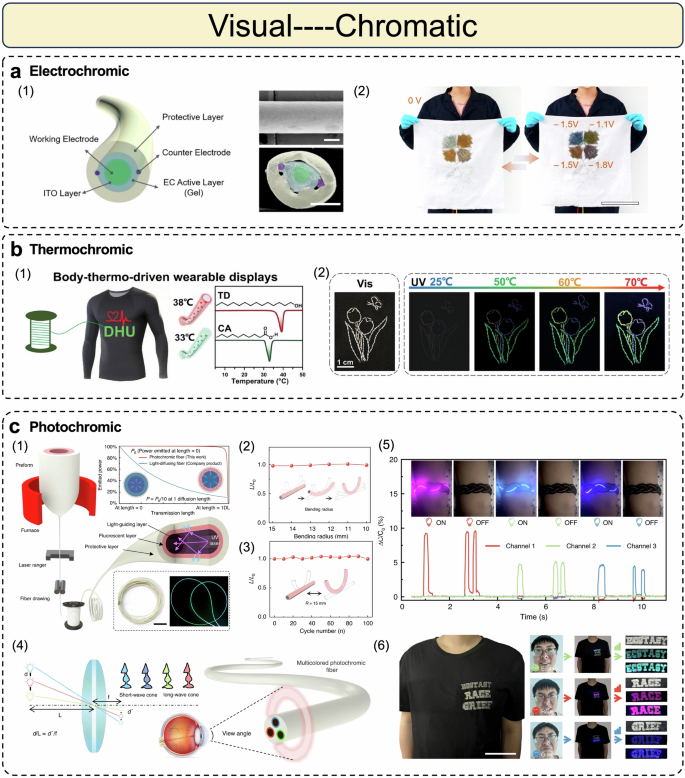

Electrochromism is when certain materials reversibly switch colors or optical properties (absorbance/transmittance/reflectance) via redox reactions under a small external voltage or current49. Various electrochromic materials, including metal oxides (e.g., titanium oxide, TiO2; bismuth oxide; and vanadium oxide, V2O5)50,51,52or organic materials (viologens, Prussian white, PW; and polyaniline, PANI) have also been investigated for their potential applications in multicolor and flexible electrochromic fibers53,54. Electrochromic fibers have been extensively studied for their widespread use as displays, wearables, and other versatile electro-optical elements. It is worth noting that fabrics integrated with electrochromic fibers have the potential to revolutionize the fashion industry, offering infinite design possibilities that could facilitate the development of wearable displays and expressive garments. However, because of the complexity of the device components, most EC devices have been assembled using a sandwichlike plane structure, leading to poor breathability, adhesion, and implantability for clothing or fabric applications48,55,56. Current electrochromic fibers include three typical structures: coiled, helically coaxial, and wrapped. Li et al.57 first prepared EC fibers based on a helically twined electrode structure and obtained different EC fibers with multiple color changes. Furthermore, Lin et al.58 constructed EC fibers through the electrodeposition of EC materials and electrolyte-coating processes, which demonstrated rapid multiple color changes. Despite these achievements, many shortcomings and difficulties still exist that restrict the practical application of EC fibers. To improve the practicability of electrochromic fibers, Fan et al.59 present electrochromic (EC) fibers with long-range controllability and multi-environmental stability that were continuously prepared using custom-built equipment, as illustrated in Fig. 4a. The introduction of various EC-active materials (viologens) and a distinctive device configuration (parallel dual-counter-electrode structure) enabled the attainment of rapid color alterations over extended timeframes. These fibers were knitted to create intelligent color-changing textiles with intricate patterns, exemplifying prospective EC fiber applications in vision-interactive contexts. In another work, Stylios et al.19 prepared a novel electrochromic composite yarn and produced four intelligently changing patterned fabrics. By analyzing the brainwaves of 20 subjects when viewing different bright patterns, it was demonstrated that changes in patterns affect the emotional attributes of the user. Therefore, strategic manipulation of these intelligent e-textile designs can enable human-emotional interaction.

a Electrochromic fiber59. (1) Structural scheme, top view, and cross-sectional SEM images of the EC fibers. (2) Digital photographs of large-area embroidery with smart color-changing flowers composed of multiple EC petals. Copyright©2020, ACS. b Thermochromic fiber65. (1) Schematic showing the health monitoring clothing prepared through the personalized customization of thermochromic fluorescent fibers. (2) Gradient color variation of a pattern embroidered by the thermochromic fluorescent fibers with different discoloration temperatures. Copyright©2024, Wiley‐VCH GmbH. c Photochromic fiber68. (1) Schematic illustration of the fabrication of the photochromic fiber. (2) Dependence of luminance ratio on bending radius. (3) Dependence of luminance ratio (L/L0) on bending cycle (radius of curvature R = 15 mm). (4) Schematic illustration of multicore photochromic fiber as viewed from the human eye. (5) Correspondence between capacitance response and light-emitting colors under different touch positions. (6) Wearable interactive display system that reflects the user’s emotional state based on facial expression. Copyright©2024, The Authors.

Thermochromism is a phenomenon in which a polymer changes color in response to temperature variation (specific temperature range)60. Thermochromic materials are compounds or mixtures that change their visible absorption spectra when heated or cooled. It has discoloration characteristics at a specific temperature, showing a new color and restoring to the original color when the temperature is converted to the initial temperature61. Based on chemical composition and discoloration mechanism, the thermochromic materials are categorized into inorganic, liquid crystal, and organic substances62,63,64. Therefore, reversible thermochromic materials can prepare fibers with chromic properties. Two main ways to prepare thermochromic fibers are composite fibers and surface coatings. However, their development is hindered by monotonous colors, low-contrast color changes, and poor reversibility. To extend the range of color variations, Zhan et al.65 focused on full-color “off–on” thermochromic fluorescent fibers obtained by the self-crystallinity phase change and Förster resonance energy transfer (FRET) mechanisms, as shown in Fig. 4b. The thermochromic fibers display favorable mechanical properties, high fluorescent emission contrast, excellent reversibility, and a controlled response temperature. This study presents a new approach to designing and researching visually interactive e-textiles with more comprehensive performance.

Photochromism is a reversible light-induced color change observed in organic, inorganic, or organometallic materials66. In contrast with other chromatic fibers, luminescent color-changing fibers emit light independently and display color changes in different wavelengths regardless of ambient brightness. Considering light is a simple and readily accessible energy source, photochromic materials show diverse application prospects in many domains. Previously, photochromic textiles were produced by conventional dyeing and screen printing, microencapsulation indirect treatment, chemical grafting, etc67. Recently, many efforts have been made to produce various biobased photochromic fibers. Li et al.68 used polymethyl methacrylate material as the inner light-guiding layer and integrated fluorescent composite material with a lower refractive index in the outer layer, developing a mass-producible photochromic fiber using the thermal drawing technique, as shown in Fig. 4c. Moreover, multicolor display in a single fiber was achieved by regulating the fiber structure and optimizing mixed-color effects through design and structural analysis. These fibers were combined with other perceptual interaction components and computer terminals to enable dynamic information exchange through external signal control of fiber pattern and brightness. This work provides a new perspective and inspiration to the existing field of fiber display interaction, paving the way for visual interaction.

Visual interaction e-textiles combine aesthetic appeal with functional capabilities and deliver a range of interactive signals. Whether through illumination or color change, these visual interaction e-textiles can bring users richer visual sensations. Visual interaction e-textiles have shown potential for development and application value in medical, sports, and entertainment fields. Despite notable advancements in the technology and design of textiles that light up or change color, issues such as operational stability and high manufacturing costs still need to be addressed. Therefore, future research should prioritize improving the durability of these e-textiles and reducing their production costs to facilitate their wider use and development in many fields.

The haptic interaction e-textiles

As the earliest mature and crucial part of the human sensory system, Haptics plays a vital role in learning, movement, communication, and environmental perception69. Haptic interactive e-textiles can be subdivided into two core components based on their functional characteristics: haptic sensing e-textiles and haptic feedback e-textiles. The haptic sensing e-textiles focus on efficiently and accurately capturing and converting external tactile stimuli into electrical signals for subsequent processing and analysis70. In contrast, the haptic feedback e-textiles are dedicated to reconstructing and feeding the digital tactile information to the user using specific physical effects or stimuli, such as vibration and temperature change, to realize the closed-loop interaction of tactile perception71. However, there are still many challenges to achieving highly intuitive and natural haptic interaction transmission. The focus is on the development of scalable and conformal e-textiles. The research community has been exploring new materials and manufacturing processes to break through these technical bottlenecks in recent years.

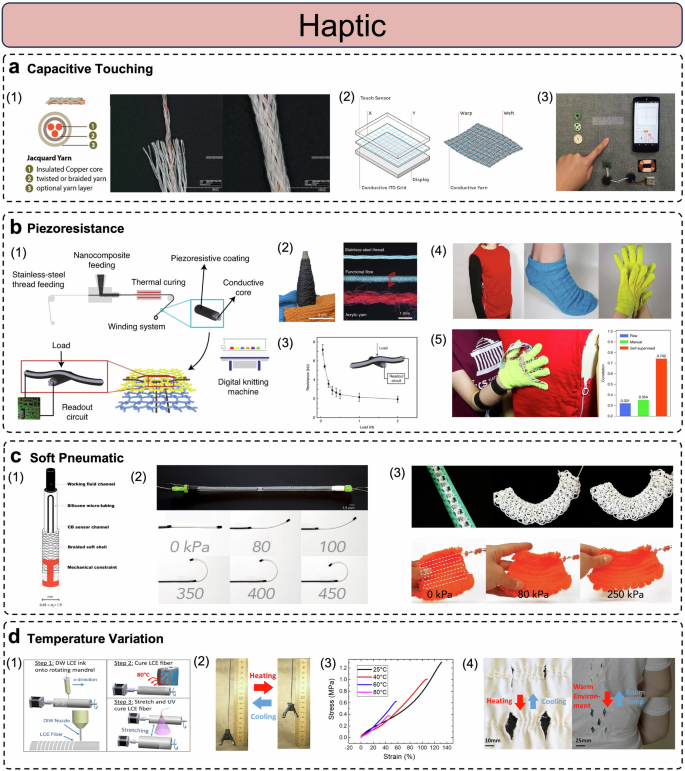

Haptic sensing e-textiles can be divided into two main categories according to the differences in sensing technology: capacitive and piezoresistive sensing mechanisms72. The capacitive sensing e-textiles are designed to sense touch movements by measuring changes in the capacitance value between capacitive pole plates in the fabric. The piezoresistive sensing e-textiles use the property that the piezoresistive material embedded in the fabric changes its resistance value when subjected to pressure to sense external tactile stimuli. Google’s Jacquard technology73 is the most representative of the research on haptic sensing e-textiles. It incorporated conductive fibers woven into the fabric, transforming the textiles into flexible electronic touch interfaces that enable remote control of electronic devices, as shown in Fig. 5a. This innovation has introduced a novel paradigm for tactile interaction in haptic e-textiles. The capacitive sensing e-textiles have the advantage of being multi-touchable, but their design is relatively complex and may be affected by fabric deformation. On the contrary, piezoresistive haptic sensing e-textiles have the advantages of simple structure and fast response speed. Luo et al.74 developed e-textiles based on coaxial piezoresistive fibers (conductive stainless-steel threads coated with a piezoresistive nanocomposite) produced using an automated coating technique, as shown in Fig. 5b. To fabricate 3D conformal tactile textiles in a scalable manner, they used digital machine knitting to seamlessly integrate the functional fibers into shaped fabrics and full-sized garments that can be used to record, monitor, and learn human-environment interactions.

a Capacitive Touching73. (1) Jacquard yarn structure. (2) Textile structure of multitouch capacitive panels. (3) Schematic illustration of human touch interaction. Copyright©2015, ACM. b Piezoresistance74. (1) Schematic of the scalable manufacturing of tactile sensing textiles using a customized coaxial piezoresistive fiber fabrication system and digital machine knitting. (2) The piezoresistive functional fiber (>100 m) and sensing fabrics. (3) The resistance profile of a typical sensor (composed of two piezoresistive fibers) in response to pressure (or normal force). (4) Digitally designed and automatically knitted full-sized tactile sensing wearables: vest, sock, and glove. (5) Procedure for self-supervised correction of the vest using the response of the calibrated glove as the reference. Copyright©2021, Springer Nature. c Soft Pneumatic80. (1) Schematic illustration of Multilayer fiber composite. (2) Temporal shape change from line to varying bending radii curves. (3) Stiffness changing hand-knitted collar and inlay-knitted contractible-bending swatch. Copyright©2021, ACM. d Temperature Variation77. (1) Schematic of the three-step fabrication process of an LCE fiber. (2) Demonstration of the two-way, stress-free actuation of the LCE fiber upon heating and cooling above its TNI. (3) Stress-strain curves of the LCE fiber at various temperatures. (4) Demonstration of the LCE bright shirt demonstrating pores for improved heat transfer and sweat evaporation during exercise. Copyright©2019, ACS.

Researchers have explored a variety of techniques for haptic feedback, including electrical75, pneumatic76, deformation77, and vibration78. These technologies not only provide more intuitive and efficient aids for haptic interaction but also greatly enrich the depth and immersion of the VR/AR interaction experience79. Among them, pneumatic technology offers the unique advantage of generating thrust or pressure feedback through compressed air or gas flow, providing the user with a more natural and dynamic tactile experience. To support designers, Afsar et al.80 built on fluidic artificial muscle research to develop OmniFiber – a soft, line-based material system for designing movement-based interactions, as shown in Fig. 5c. It exhibits perceivably strong forces, up to 19 N at 0.5 MPa, and a high speed of linear actuation, peaking at 150 mm/s. OmniFiber has a range of deformation geometries, including extension, contraction, bending, curling, and microtexture feedback. This advanced technology allows us to explore deeper into the research and development of haptic feedback experiences that closely match and precisely respond to human perception.

Moreover, Shape memory fibers are intelligent materials that can respond to environmental stimuli (temperature, magnetic fields, electric fields, pH levels, and ultraviolet radiation), with the ability to return to their original shape after deformation81. Due to their remembering, responding, and adapting abilities, these fibers have extensive research and good application potential in interactive e-textiles. Especially temperature-variation materials not only adjust their shape to the rise and fall of the ambient temperature, but they also effectively regulate the microclimate inside the textile. Traditional textiles have inherent limitations in terms of comfort, particularly in their inability to adjust their thermal and moisture properties in response to environmental changes. In contrast, temperature-variation fibers can actively adjust their structure by sensing the external environment, achieving intelligent heat and moisture management. Roach et al.77 developed a liquid crystal elastomer (LCE) fiber with reversible shape memory properties, as illustrated in Fig. 5d. This fiber demonstrated contraction upon heating and expansion upon cooling. Consequently, the LCE fibers have been engineered into intelligent e-textiles to regulate body temperature. Incorporated into smart shirts, the fiber structure opens up when the wearer’s body or ambient temperature rises and closes when the temperature drops, creating adjustable convective cooling and sweat evaporation for effective human thermal management.

In conclusion, the accelerated advancement of haptic interaction technology, particularly the incorporation and advancement of high-density tactile sensing systems and diversified haptic feedback technology, is progressively advancing us towards a more natural, efficient and emotional human-computer interaction era.

The auditory interaction e-textiles

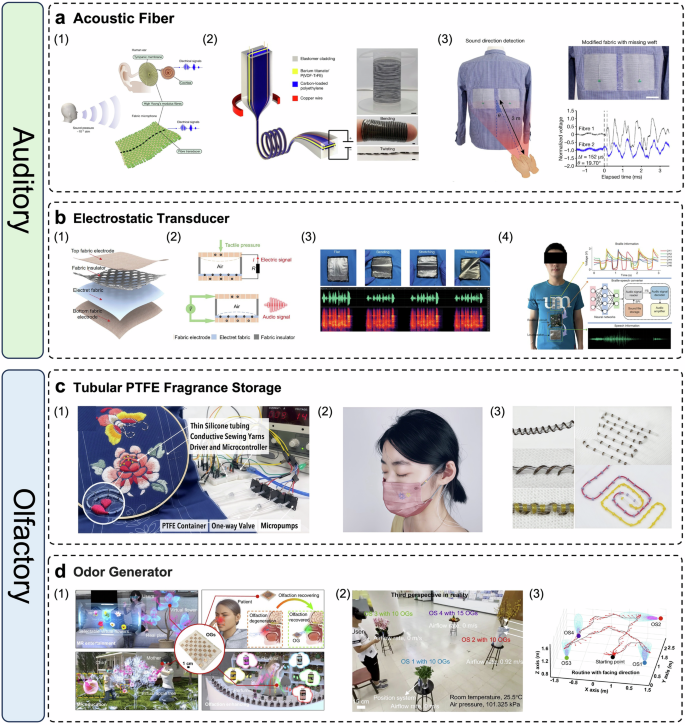

Auditory perception is a fundamental mode of communication, offering immediacy and direct interaction. Sound has distinctive functional, symbolic, and signaling attributes. Its acoustic properties, such as volume, pitch, and timbre, can deliver comprehensive interaction information to users82. Auditory interaction design mainly utilizes the sound itself and the information characteristics the sound conveys for experience design. Neurophysiological studies have shown that auditory stimuli can augment the processing of visual cues, thereby facilitating better environmental adaptation83. Related research indicated that audio feedback interaction can give users a higher emotional valence experience than vibration feedback interaction84. The intelligent fibers mainly used for realizing human auditory interactive perception are thermally drawn composite piezoelectric and triboelectric fibers. Yan et al.85 produced an “acoustic fabric” by weaving thermally stretched composite piezoelectric fibers into fabric yarns, which can transform mechanical vibrations into electrical signals, giving the fabric sound sensitivity, as shown in Fig. 6a. This fabric’s design is inspired by the human auditory system converting tiny sounds imperceptible to the ear into bending vibrations on the fabric surface. The minimum sound-detection capability is 0.002 Pa (40 dB, the sound pressure level in a quiet library), outperforming many other thin-film-based acoustic sensors. Its capacitance remains stable over 3000 cycles of bending or twisting. This innovative design of acoustic textiles has applications in multiple fields. For instance, it can be utilized in the security sector to determine the origins of gunfire. In the healthcare sector, it can also enhance the directional hearing capabilities of individuals wearing hearing aids. Furthermore, this fabric can monitor various physiological parameters when integrated into garments. This fiber is also machine washable and drapeable, making it an ideal option for wearable technology. In another work, Li et al.86 proposed a novel Braille-to-speech conversion system, the core component of which is a bifunctional electrostatic transducer constructed from fabric, which is well-designed and easy to be embedded in various textiles, as shown in Fig. 6b. The stability of ET is also studied by pressing the ET using a force rod repeatedly with a pressure of 8.8 kPa and a frequency of 2 Hz for 3900 cycles. Based on the electrostatic sensing mechanism, the transducer has the dual functions of tactile sensing and sound output and realizes the seamless conversion from Braille recognition to speech playback. This work demonstrates a new approach for further developments of advanced assistive technology toward improving the lives of disabled people.

a Acoustic Fiber85. (1) Design and principles of fabric microphones. (2) Schematic of preform-to-fiber thermal drawing and fiber poling. (3) Examples of applications of the woven acoustic fabric integrated into shirts. Copyright©2022, Springer Nature. b Electrostatic Transducer86. (1) Blow-up schematic of the textile-integrated ET comprising fabric electrode, fabric insulator, and electret fabric. (2) The operating principles of the ET serve as a tactile sensor and a loudspeaker, respectively. (3) Acoustic wave of “Wearable electronics” generated from ET at different states, including flat, bending, stretching, and twisting. (4) Integration of ETs with clothing and the process of Braille-to-speech translation. Copyright©2024, Wiley‐VCH GmbH. c Tubular PTFE Fragrance Storage91. (1) The system design of ScenThread. (2) Mask releasing the scheduled scents for Olfaction Recovery Training. (3) The method is embedded into traditional embroidery. Copyright©2021, ACM. d Oder Generator92. (1) Schematic diagram of the advanced OG-based olfaction interfaces. 2–3 Application of the MR system with the olfaction interfaces integrated. Copyright©2024, Springer Nature.

Although acoustic fibers offer significant advantages in terms of flexibility and lightness, they still face many limitations and challenges in practical application scenarios, such as sound conversion efficiency and environmental adaptability. Therefore, future research should focus on exploring the optimal balance between functionality and comfort in auditory interactive e-textiles.

The olfactory interaction e-textiles

Compared to the extensive research on the development of visual, haptic, and auditory feedback technologies, olfactory-generating technologies have yet to obtain much attention in recent years. The utilization of olfaction feedback systems has the potential to stimulate human emotion, increase alertness, provide clinical therapy, and establish immersive virtual environments87,88. As such, the sense of smell is considered one of the most potent conduits of emotional memory89. Olfactory design typically employs a variety of scents to forge distinctive interactive functionalities. Representatives interacting with the olfactory senses are aromatic fibers and miniaturized odor generators (OGs). Aromatic fibers can emit natural fragrance by loading the fragrance masterbatch onto the fiber using different preparation techniques such as blended spinning and composite spinning. Tian et al.90 regulated the aroma intensity of aromatic fabrics based on increasing or decreasing the adhesion of microcapsules to cotton fabrics, thus promoting textile functionality. However, the scent tends to be monolithic and does not offer the combination and variation of scents that perfumes do. Furthermore, fragrances may evaporate or break down over time, causing the fiber’s odor to diminish or disappear.

In addition, the development trend of next-generation olfactory interfaces is approaching wearable formats with miniaturized design to achieve rapid olfaction feedback and generate localized odorous environments. Wang et al.91 proposed ScenThread, a novel threaded olfactory display that can be woven into textiles, as shown in Fig. 6c. ScenThread includes a tubular PTFE fragrance storage, a lightweight vibration-free piezoelectric pump system for conveying fragrances, a breathable silicone tube for diffusing fragrances, and a conductive yarn heating module for accelerating the release of fragrances. ScenThread can be embedded in textiles through hand embroidery, giving people a unique olfactory textile interaction experience. To explore and realize more refined olfactory interaction experiences in virtual environments, Liu et al.92 developed a series of AI-driven, wearable olfactory interfaces based on high-performance OGs for realizing latency-free MR and fast olfaction recovery applications, as shown in Fig. 6d. The OGs adopt a solenoid valve structure, exhibiting technical advances in terms of millisecond-level response time, milliwatt-scale power consumption, overall size, stability, and ultrahigh number of odor supplies. The approach may serve as a foundation for establishing an information channel based on olfaction with the potential for application.

In conclusion, olfactory interactive e-textiles are in the stage of technological exploration and preliminary application. For example, the accuracy and controllability of the odor release of olfactory e-textiles also need to be further optimized. In addition, achieving a more natural and realistic olfactory interaction experience is a major challenge for olfactory interactive e-textiles. The user’s perception and acceptance of odor varies from person to person and requires more personalized design and optimization.

The integration strategies of sensory interactive e-textiles system

Intelligent e-textiles represent a growing field that combines traditional textile technology with advanced innovative materials, which integrated products of conventional yarns and functional fibers. Different integration strategies, which include weaving, knitting, braiding, and embroidering, affect the performances of interactive e-textiles, like the mechanical, thermal, acoustic, optical, and electrical properties93. The integration systems must be flexible, lightweight, stretchable, and washable to offer superior usability, comfort, and non-intrusiveness94. Therefore, selecting and designing the optimal textile integration strategies are essential for advancing fiber-shaped electronics with the desired functions and properties. Among all of the sensory interactive e-textiles, light-emitting and sensing textiles have been mostly investigated. This section explores various integration strategies for luminescent and sensing fibers to analyze whether the electrical properties of the electronic fibers are maintained.

Integration strategies for luminescent fibers in e-textiles

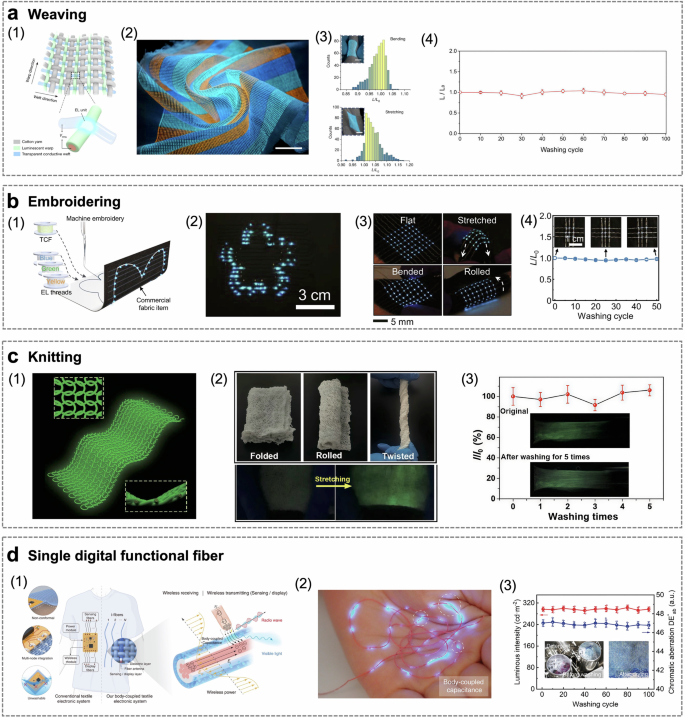

Light-emitting and display textiles represent an innovative convergence of textile engineering and optoelectronics, where fabrics are designed to emit light or display visual information. The fabrication methods must be carefully designed and selected to ensure that luminescent e-textiles have the necessary washability, deformation adaptability, and comfort in practical applications. Weaving refers to forming woven fabrics using yarns as warp and weft in various fabric structures with many regular interweaving points, resulting in better mechanical properties and stable structures—traditional yarns, such as cotton and polyester yarns. Peng et al.95 used the conductive weft and luminescent warp fibers woven with cotton yarn on an industrial rapier loom, each interlaced weft and warp forming an EL unit (Fig. 7a–1). Weaving conductive weft and luminescent warp fibers form micrometer-scale electroluminescent units at the weft–warp contact points. They also obtained colorful textiles (Fig. 7a–2) with uniformly spaced EL units by doping elements, such as copper and manganese, into the ZnS phosphor. After 1000 cycles of bending and stretching (Fig. 7a–3), the intensity for a vast majority of the EL units remained stable (with <10% variation). Moreover, the intensity of the majority of the EL units varied by <15% even after repeated folding along different directions, and the intensity of the EL units at the folding line remained stable over 10,000 cycles of folding in each folding direction, indicating superior durability over traditional film displays. Further, the brightness of the EL units endured 100 cycles of accelerated washing and drying (Fig. 7a–4). By weaving conductive and luminescent fibers with cotton yarns, EL units can be formed directly within the textile, thus introducing a functional, large-area display textile. In addition, the network weaving structure of the weft and warp yarns, each EL unit in the light-emitting textile can be uniquely identified and illuminated in a programmable manner using drive circuits, which dynamically control the pixels individually in real-time according to the incoming digital signals, increasing the visual interaction.

a The woven light-emitting textile95. (1) Schematic showing the weave diagram of the display textile. (2) Photograph of a functional multicolor display textile. (3) Statistical distribution showing minor (<10%) variations in luminance of bending and stretching. (4) The electroluminescence intensities before and after washing. Copyright©2021, Springer Nature. b The embroidered light-emitting textile97. (1) Schematic illustration of using machine embroidery for crafting light-emitting textiles. (2) Photographs showcasing the light-emitting textiles embroidered. (3) Photographs of light-emitting textiles under stretching, bending, and rolling. (4) Relative EL intensity of the light-emitting pixels during multiple laundry cycles. Copyright©2024, The Authors. c The knitted light-emitting textile98. (1) The ML fabric has a knit structure. (2) Photographs of ML textiles subjected to deformations including folding, twisting and rolling. (3) ML intensity of ML textiles after washing five times. Copyright©2023, Tsinghua University Press. d The single digital function fiber99. (1) Design and principle of the body-coupled interactive fiber. (2) Photograph of i-fiber being wirelessly powered by placing it on the hand and coupling the surrounding EM energy. (3) Washability of our i-fiber woven textile, including color fastness and luminous intensity stability. Copyright©2024, The Authors.

Alternatively, light-emitting textiles can be integrated with embroidery technology. Machine embroidery has been well-established and widely used in the textile industry for mass production96. Machine embroidery uses two threads, an upper thread and a bobbin thread, which run along the top and bottom of the fabric to generate interlaced locked stitches. Compared to the woven method, which is restricted to either straight lines or rectangular patterns, embroidery offers a unique ability to create a wide range of decorative designs, from simple to intricate, on any kind of fabric item. This makes it a craft that is difficult to replicate by knitting or weaving. However, current EL threads are challenged to meet the strict requirements of machine embroidery, such as having a high tensile strength of at least 6 N, a moderate elongation at breakpoints below 100%, and a smooth surface finish97. Cho et al.97 presented embroiderable multicolor EL threads in blue, green, and yellow that are compatible with universal embroidery machines (Fig. 7b–1) and can be applied to stitching decorative designs on various consumer fabrics (Fig. 7b–2). Figure 7b–3 shows an 8 × 8 array of light-emitting pixels that maintained stability even when bent, stretched, or rolled, without visible degradation in their emission performance. Multiple wash cycles (>50 cycles) showed no significant damage to the L/L0 of the illuminated pixels (Fig. 7b–3). Compared to traditional EL threads used for weaving or knitting, these are thinner and more durable, making them suitable for machine embroidery when crafting light-emitting textiles with custom designs.

Different from woven fabrics, knitted fabrics are formed by interloping one or more sets of yarns in a needle bed. The mechanical force brought by the unique looping structure puts them in a compressed state under natural conditions. As a consequence, they show great properties in elasticity, stretchability, and mechanical adaptability. The geometric shape remains stable under repeated bending and deformations, indicating a significant improvement in durability and recoverability. Therefore, the ML fibers can maintain better flexibility during the knitting process. Chang et al.98 developed a novel ML composite fiber consisting of a thin polyurethane (PU) core and ZnS: Cu/polydimethylsiloxane (PDMS) shell and can also be woven into intricate textiles, such as weft-knit textiles, which feature abundant curved locations with significant curvature (Fig. 7c–1). As shown in Fig. 7c–2, the ML textile exhibits satisfactory flexibility, and it can be folded or rolled without external force support and can be manually twisted into a tight rope. When manually stretched in a dark environment, the entire ML textile can be fully lightened. Besides, encapsulated with the hydrophobic PDMS, the ML textile can maintain its original brightness after washing for five rounds (Fig. 7c–3). The weft knit textile from the continuous ML fiber can be easily delighted by manually stretching and also serves as a visual strain sensor when driven by human motions.

However, the integrated systems mentioned above must be equipped with rigid batteries or communication chips. This limits the seamless integration of sensory interactive textile technologies, the lasting energy efficiency, and the comfort of the wearer’s experience. Yang et al.99 proposed a chapless body-coupled energy interaction mechanism to overcome this limitation, as shown in Fig. 7d–1. When the soft fiber is placed in the palm, the interface contact capacitance can effectively capture the ambient EM energy and induce the fiber to emit light (Fig. 7d–2). The chipless wireless textile exhibits good breathability (~604.8 mms−1, ~1.99 g cm−2 h−1), nearly 100 times higher than chip-based e-textile systems. After 25 standard washes, our textile electronic maintains its original appearance and performance (Fig. 7d–3). The luminous brightness of the fabric is not significantly attenuated, which proves that it has good washing resistance, long-term working stability, moisture resistance, sweat resistance, and abrasion resistance. In contrast, this fiber eliminates the constraints of chips and battery assemblies and can be seamlessly integrated into the modern textile industry, addressing the issues of comfortability, integration, and endurance. This hapless interactive intelligent fiber can be applied to daily textiles such as clothing and apparel, which opens up new possibilities for human-clothing interaction and sensory interaction.

Integration strategies for sensing fibers in e-textiles

Haptic interactive sensing e-textiles are other popular integrated systems developed so far. Integration methods play a crucial role in determining the sensitivity, durability, and comfort of these sensing e-textiles23,46,100,101. For example, by using special weaving techniques, precise positioning and uniform distribution of the sensing fibers in the fabric can be achieved, thereby improving the sensitivity and accuracy of the sensor. In addition, certain methods can reduce crossover and interference between sensing fibers, further improving sensing performance. In addition, choosing the right integration method is critical to balancing the comfort and durability of the sensing e-textiles.

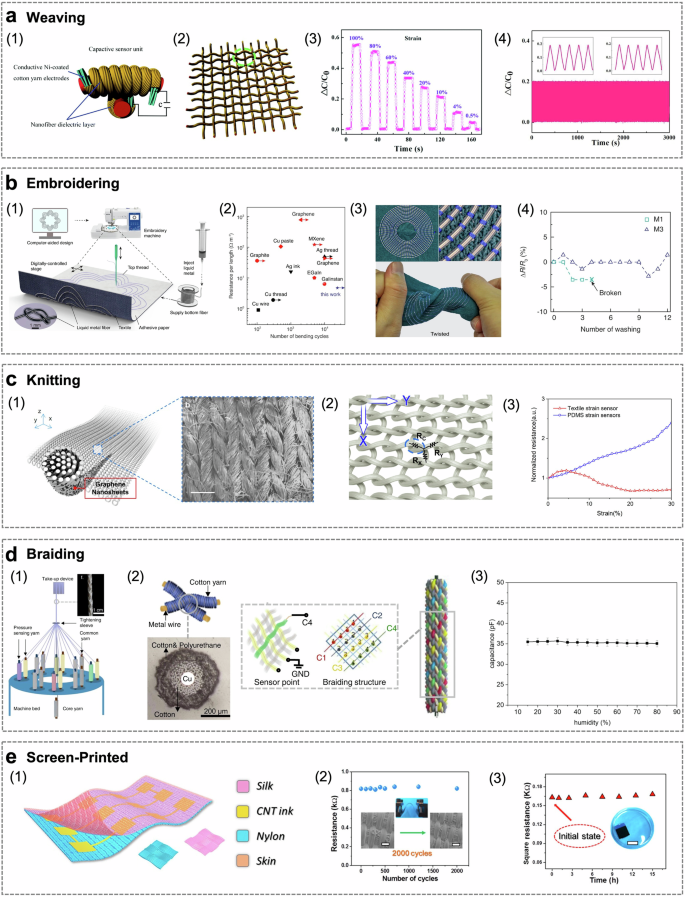

Woven fabrics typically provide a more uniform and larger area of pressure sensitivity distribution due to their uniformly dense interlacing points and stable structure during deformation. At the same time, woven fabrics are also endowed with abrasion resistance beyond that of normal materials due to their unique weaving process, ensuring good integrity and durability over a long period of time. You et al.102 constructed a stretchable GO-PNF/NiCY elastic composite yarn (Fig. 8a–1) that can be woven into a large-area fabric, as shown in Fig. 8a–2. In this fabric, mechanical sensor units were formed at each cross-contact. These sensors can be applied during various wearable occasions, such as bending, folding, movement, and elongation, due to good elasticity and stretchability. Figure 8a–3 illustrates the dynamic instantaneous capacitance response to varying strain (ranging from 0.5 to 100%) under a constant voltage of 1 V. Therefore, the sensing e-textiles have good elasticity, a rapid response rate, relatively high sensitivity and a wide range of strains. At the same time, the sensing e-textiles during 1000 stretching–releasing cycles under a relatively small strain of 10%, as illustrated in Fig. 8a–4.

a The woven sensing textile102. (1) Schematic illustration of the capacitive sensor unit. (2) The electronic fabric with a woven structure. (3) Dynamic instantaneous capacitive response to varying strain (ranging from 0.5–100%). (4) Performance of the sensor unit during 1000 stretching-releasing cycles. Copyright©2018, The Royal Society of Chemistry. b The embroidered sensing textile103. (1) Illustration of the digital embroidery process. (2) Mechanical robustness test results. (3) Images of embroidered textiles subjected to folding and twisting. (4) Machine washing test results. Copyright©2022, Springer Nature. c The knitted sensing textile104. (1) Schematics of a weft-knitted textile. (2) Schematic vertical view of the textile surface annotated showing three components of a fiber bundle cells’ resistance. (3) The typical negative differential resistance tensile response of a graphene-based textile strain sensor. Copyright©2022, ACS. d The braided textile106. (1) Schematic illustration for the fabrication of a braided electronic cord. (2) A braided electronic cord based on core-spun pressure-sensing yarns. (3) Capacitance performance test results of electronically braided wire at different humidity. Copyright©2022, Springer Nature. e The screen-printed textile107. (1) Structure design and sensing mechanism of the e-textile. (2) Resistances of the electrode when variable degrees of bending. (3) Resistances of the electrode after being immersed in water for different times. Copyright©2018, ACS.

In addition, the fabric integration method of embroidery is well suited for the development of sensor-electronic fabrics. The most notable feature of embroidery is that the yarn arrangement can be flexibly designed on the substrate according to the demand, and any shape of a circuit can be formed on the surface of the fabric, which provides a great degree of freedom for the development of sensor electronic fabrics. At the same time, it retains the softness and comfort of the fabric, enabling sensor electronics fabrics to provide a more comfortable wearing experience when fitted to the human body. Lin et al.103 demonstrated electronic textile systems with functionalities in near-field powering and communication created by digital embroidery of liquid metal fibers (Fig. 8b–1). The liquid metal fibers can achieve a fill ratio of ~95% and electrical resistance per length of ~4.2 Ω m−1, which substantially exceeds existing conductive textiles with comparable mechanical robustness (>104 bending cycles), as illustrated in Fig. 8b–2. Textiles embroidered with liquid metal fibers maintain robust electrical resistance (<1% variation) while being folded and twisted (Fig. 8b–3). The embroidered spiral inductors remained functional when over 10 h of machine washing (12 cycles, <3% change in resistance), as illustrated in Fig. 8b–4. Consequently, the advantages of embroidery undoubtedly open up a new path full of innovations and possibilities for the development of sensor-electronic textiles.

In another work, Yang et al.104 prepared a graphene strain sensor with a weft-knitted textile substrate, as shown in Fig. 8c–1. A basic textile unit comprises three sections of the fiber bundle, together denoted as a fiber bundle cell (Fig. 8c–2). A graphene-based textile strain sensor’s typical negative differential resistance tensile response (Fig. 8c–3). The textile sensor at 0–30% relative strain differs from the usual positive resistance variation sensor, which can provide a reference for the understanding and design of next-generation textile sensors and intelligent wearable devices. Knitting has significant advantages in making tactile-sensing garments. First, the fabrication process is simpler, whereas woven fabric must be cut and sewn to form a garment, full-garment machine knitting can directly manufacture wearables with arbitrary 3D geometry105. Second, the interlocking loops of yarn used in knitting create a softer stretcher fabric, which ensures comfort and compatibility during monitoring. Furthermore, the inherent flexibility of knitted structures supports diverse designs in patterns and textures. The loop configuration of these fabrics also predisposes them to deform easily, making them ideal for incorporation into flexible strain sensors.

Braiding is another important manufacturing method for continuous and large-scale intelligent textiles. Fibers and yarns are interwoven biaxially or triaxially to integrate multi-dimensional braided functional materials of various types. The braided electronic cord is in a miniaturized form, suitable for being integrated with various occasions in life. Tao et al.106 prepared an imperceptible, designable, scalable braided electronic cord for capacitive strain sensors (Fig. 8d–1). A corresponding higher magnification image of a typical core-spun yarn cross-section with a diameter of 440 μm was exhibited in Fig. 8d–2. The sensing point and the repeating braiding structure of a braided electronic cord with only 2.5 mm in diameter, as shown in Fig. 8d–3. It can work typically in different ambient temperatures and humidity (Fig. 8d–4), and its washable times >10 times). Therefore, it can be concluded that the braided electronic cord can be used repeatedly for a long time against repeated mechanical loads, which is suitable for daily use. Additionally, this kind of miniaturized interface, which can realize various interaction methods with a small number of channels, can be easily used on various occasions, achieving an imperceptible user experience. In summary, compared to weaving and knitting methods, braiding has higher adaptability and degrees of freedom. It is not limited to specific weaves or stitches and is a textile fabrication method that can integrate functional yarns in various angles, interweaving forms, and geometric shapes.

In addition, some researchers have also used screen printing methods to prepare flexible sensing fabrics. Because of its high productivity, it can be manufactured on a large scale on comment fabrics. This is very important for preparing large quantities of sensing e-textiles. A self-powered textile-based gesture/touch sensor (Fig. 8e–1) was developed by screen-printing a CNT/PU layer with defined patterns on nylon fabric and placing silk fabric on top as a frictional layer107. The CNT/PU-coated textile showed an air permeability of ~88 mm s-1, indicating the breathability of the textile system. When used as a sensor, a maximum sensitivity (relative change in electrical signal per unit pressure) of ~0.048 kPa-1 was achieved over the pressure range of 0–100 kPa. After repeated bending for over 2000 cycles, the electrodes’ comparison indicates no obvious difference, which is further evidence of the electrode’s excellent durability. (Fig. 8e–2) At the same time, the electrodes have excellent washable properties, and the square resistances of the electrodes were tested after being immersed in water at different times (Fig. 8e–3).

Intelligent e-textile design paradigm

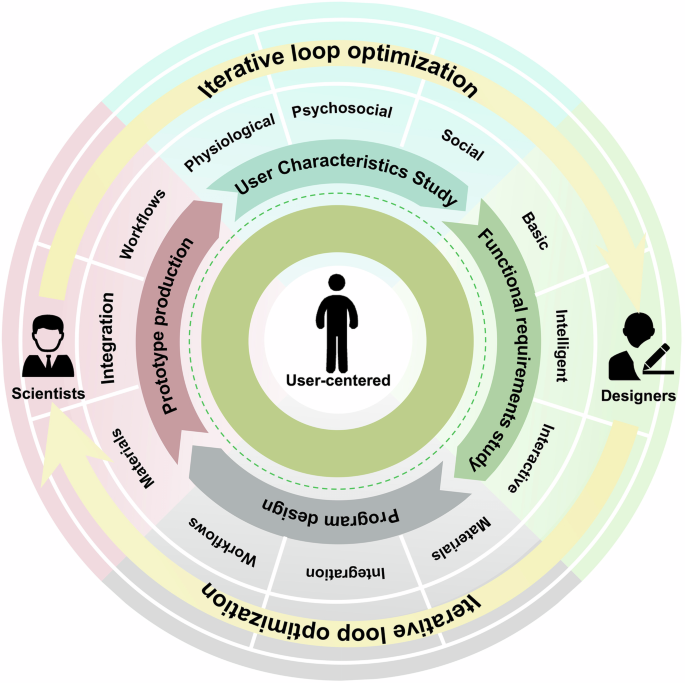

To better promote the design and development of intelligent interactive textiles and create a design model for sensory interactive textiles, this paper summarizes a generic design paradigm for developing intelligent textiles. Currently, design paradigms in intelligent textiles predominantly focus on advancing electronic functionalities108,109,110,111. While these advancements have driven the sector’s growth, they often fail to meet users’ interactive demands or consider the full spectrum of practical applications. Users expect more than functionality from intelligent textiles. They seek products that interact with them and satisfy their unique preferences. Addressing these shortcomings, this paper proposes an innovative design and development model tailored for sensory interactive textiles. This model prioritizes advancing electronic features and fulfilling users’ interactive demands, striving to deliver a more convenient, comfortable, and personalized brilliant textile experience. Nowadays, user demands have become the fundamental standard for evaluating the user-friendliness of interactions. The unique interactive capabilities of innovative textile technology profoundly demonstrate the intimate relationships between people and e-textiles. This highlights the critical importance of adopting a user-centered design philosophy. Accordingly, this paper presents a new design model for interactive e-textiles anchored in the user-centered approach. The process comprises five essential phases: User Characteristics Study, Functional Requirements Exploration, Program Design, Prototype Production and Iterative Loop Optimization. This model is designed to ensure that sensory interactive textiles meet user requirements and enhance the user experience during interactions, as shown in Fig. 9.

Interactive e-textile design paradigm.

User characterization study

Humans are the ultimate users of sensory interactive e-textiles, and their demands and satisfaction directly determine the properties of interactive e-textiles. Consequently, a fundamental step in the design model for these textiles involves an in-depth analysis of the target demographic’s traits. This includes examining physiological, psychological, and social characteristics through diverse methods such as surveys, interviews, and direct observations. Embracing a user-centric design philosophy is crucial for the successful development of interactive e-textiles, necessitating a continual focus on user characteristics throughout the design and development process.

Functional requirements exploration

Exploring functional requirements in e-textiles involves an integrated assessment of their functionality, interactivity, and user experience. The primary functions include essential basic features (warmth, breathability, and comfort) and advanced features for intelligent use, such as environmental sensing and data exchange. These functionalities should be tailored to specific use scenarios. Additionally, the analysis must consider the user-textile interaction, emphasizing ease of use, comfort, and prompt feedback. This analysis ensures the designs align with user expectations and market demands.

Program design

The design of interactive e-textiles involves three primary considerations. Firstly, choosing the appropriate smart materials is essential for ensuring textiles or garments’ functional capabilities and comfort. Secondly, it is necessary to select suitable integration technologies for weaving that accommodate both hardware and software, enhancing the overall functionality of the e-textiles. This step requires careful consideration of the compatibility and integration methods among different materials to guarantee the system’s stability and reliability. Lastly, optimizing the manufacturing process is crucial. This optimization ensures the quality and strength of the garments, catering to users’ aesthetic demands, significantly improving efficiency, and reducing development costs in future production phases.

Prototype production

According to the program design, a prototype of interactive e-textiles will be made. In this process, attention is required to be paid to materials, integration technology, and process flows.

Iterative loop optimization

Developing interactive e-textiles is an iterative and cyclical process of optimization. Enhanced performance reliability and user-friendly interactions can only be achieved through continuous improvements. User evaluations are essential in this context. This method involves inviting participants to assess prototypes of the interactive e-textiles, gathering their insights on aspects such as functionality, user experience, cost perception, privacy, security, and operational stability. Based on this feedback, the product is refined iteratively to progressively enrich the user experience and functionality offered by the interactive e-textiles.

In the comprehensive process of developing intelligent e-textiles, the collaborative efforts between scientists and designers are crucial. Their combined expertise can lead to innovative and effective solutions. During prototype production, scientists mainly provide the technical details for interactive e-textiles, including integrating electronic components and sensors. Meanwhile, designers focus on the textiles’ aesthetic design, user experience, and functionality. In the iterative optimization phase, both parties should collaboratively adjust and refine the design from their respective professional viewpoints, aiming for continual improvement. In summary, the collaboration between scientists and designers in developing interactive e-textiles is crucial for enhancing technological innovation and integration. This teamwork optimizes the user experience, improves the efficiency and quality of projects, and broadens the scope of applications and potential markets.

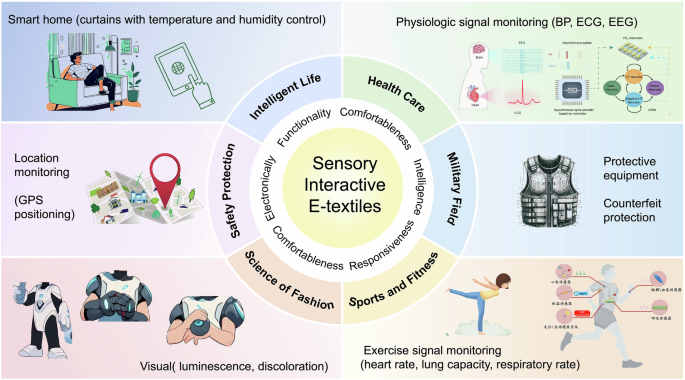

Sensory interactive e-textiles applications

With the continuous development of technology and increasing people’s demands for intelligent life, the current integrated interactive e-textiles system has shown a wide range of application prospects in various fields of people’s lives, including healthcare, sports and fitness, military, safety protection, and fashion, as shown in Fig. 10.

Sensory Interactive e-textiles application areas.

Healthcare

E-textiles have attracted considerable attention because of their potential uses in health monitoring, rehabilitation, and training assessment applications112. Interactive textiles integrated with electronic devices and algorithms can be used to gather, process, and digitize data on human body motion in real time for purposes such as electrotherapy, improving blood circulation, and promoting wound healing113. E-textiles can be used to monitor physiological signals from the patient. Different sensors such as heartbeat sensor and respiration sensor114 can be integrated into the wearable textiles to monitor the physical activity of the user. This application opens a way to remotely monitor the physiological parameters of the user115. In addition, by integrating feedback systems, rehabilitation patients can be assisted with exercise and posture adjustments to speed up the rehabilitation process. MIT has developed an innovative smart textile known as “OmniFiber.”80 Embedded within the fibers are stretchable sensors that dynamically monitor and respond to simple bending motions, mirroring the multifaceted tactile properties of human skin, such as stretchability, compressibility, and vibratory responses. OmniFiber can detect the degree of stretch or compression and offers immediate tactile feedback. This technology benefits training applications, such as aiding singers or athletes in refining their breathing techniques and assisting patients in regaining standard respiratory patterns after illness or surgical procedures.

Sports and fitness

Interactive textiles are useful in fitness, training and gesture-control or movement monitoring applications. They are used for monitoring human motion and position116, posture sensing, and gait sensing117. This technology proves particularly valuable in professional sports, aiding athletes and coaches in recording and analyzing training data to escalate their training level. Interactive e-textiles can collect information about different knee positions and decipher physical actions, such as walking, running, jumping, and crouching118. Consequently, e-textiles can sense the body’s position and muscle movements and offer feedback. Thus, we can access and then evaluate the performance of a person for further improvement. Moreover, these e-textiles facilitate sleep tracking and muscle stimulation applications. Choudhry et al.119 have made textile piezoresistive sensors using flexible conductive wires that can be used to count steps and monitor muscle movement. Wearable X has introduced Nadi X yoga pants with Bluetooth functionality120. Embedded sensors to monitor and collect comprehensive data from the wearer. When the movement is not standard, it will emit vibration feedback, reminding the wearer to make adjustments. Different vibration frequencies and intensities mean the wearer must adjust in various positions and methods. The goal is to help yoga enthusiasts adjust their posture by providing real-time feedback.

Military and safety protection

Healthcare, sports, and fitness are undoubtedly the priority areas for developing interactive e-textiles, as they are closer to human daily life. Moreover, these textiles are poised for expanded military and safety protection applications. Interactive e-textiles can be crafted into protective gear and facilitate safety monitoring and positioning. In the military, interactive e-textiles can be made into protective equipment such as bulletproof vests or hard-to-detect communication devices for better concealment. For instance, Intelligent Textiles Ltd has innovated a bright bulletproof vest incorporating modular, scalable, sensory, and concealable technologies. This vest offers bulletproof protection and enables the wearer to function as a mobile electronic network. Its embedded connectors can link with data streams, supplying power to wearable devices on demand. Lu et al.121 also prepared silk-based ionic hydrogel (SIH) fibers with excellent mechanical and electrical properties. These fibers have been woven into bright gloves designed for bionic mechanical hands, capable of emitting specific electrical signals that precisely detect hazardous conditions. In addition, Choi et al.122 displayed that can serve both as an input and output device was demonstrated by using high-resolution multicolor patterning technique. Transfer-printing of an emissive composite improved the capacitive properties and optical performance, resulting in a maximum luminance of ≈600 cd m − 2 and an SPL of ≈80 dB with 120% stretchability of the device. This approach can act as a cornerstone for applications such as portable authentication devices for storing personal information or security systems. This advancement in innovative fabric technology enhances garments’ aesthetic and interactive appeal while significantly boosting their functional value.

Intelligent life and fashion

Intelligent e-textiles hold substantial potential within intelligent home systems123 and the fashion industry124. With the development of e-textile technologies, household fabrics like curtains and rugs can not only decorate the home, but also improve the safety and comfort of living. Hu et al.125 have developed a soft, warm, and mass-producible triboelectric carpet fabric for motion monitoring and user recognition. Four behaviors including slow walking, walking, jogging and jumping are classified successfully, and four different subjects are recognized. The carpet fabric is flexible, warm, inexpensive, easy to manufacture, and compatible with the living environment, showing great potential in smart monitoring systems for home security. Intelligent e-textiles designed as household products, such as curtains, enable sophisticated home automation and management. A notable innovation by Studio XO involved combining clothing with lighting elements. The firm crafted a Bubelle garment, which incorporates embedded biosensors that detect the wearer’s emotional states. Upon detecting emotional shifts, the garment’s exterior modifies its color, thus facilitating effective emotional regulation. Till now, a range of prototypes were introduced in the electronic textiles area such as self-illuminating handbag interiors, illuminating clothes or gym kits which reflect the workout performance126.

As technology rapidly advances and the public increasingly seeks a higher quality of intelligent living, integrated innovative interactive e-textile systems have demonstrated significant potential for broad application across various daily life domains. The research and development of these textiles necessitate considering several factors, including production costs, feasibility of mass production, sustainability, and the durability and longevity of the textiles. Thoroughly addressing these considerations will enhance the development of innovative textile technologies, enabling them to fulfill society’s diverse requirements better and contribute to sustainable social advancement.

Conclusion and outlook

Interactive e-textiles expand the wearable platform possibilities for humans by improving the electrical functionality of textiles. Smartphones and other portable linked devices may eventually be replaced by these e-textiles, which are seen as the next generation of wearable technology. They hold the potential to serve as a significant interactive interface between the digital and physical realms. From the related research combined, various fields of scholars have promoted the development of interactive e-textiles from different perspectives. This paper analyses the interactive materials, integrated technologies, and design paradigms. Then, we found that the existing research still needs to improve. Firstly, most studies have neglected users’ demands for psychological interaction. Current research primarily focuses on optimizing material properties without adequately considering the psychological aspects of how intelligent materials and electronic components interact with the human body, including comfort and ease of interaction. Secondly, interactive e-textiles represent an interdisciplinary area. The available technologies and resources across various fields constrain their development. Most existing studies delved into the functional technologies of specific fields without addressing the complexities of integrated systems. Consequently, achieving comprehensive integration and enhanced efficiency in intelligent e-textiles remains a significant challenge. Thirdly, the development and manufacturing of interactive e-textiles predominantly rely on craftsmanship. Due to the involvement of advanced technologies and processes, the production costs are high, limiting their widespread market adoption. Last, the essence of interactive e-textiles is their interactivity with the human body. Nonetheless, considering the human body as the primary source of interaction data, there are ongoing concerns regarding privacy and security risks.

Summarizing the above shortcomings, we put forward four outlooks for the future development direction of interactive e-textiles. (1) Focus on user demands and improve the interactive function focus of smart e-textiles. Future development trends will focus more on technological innovation and user experience enhancement. By enabling more accurate and personalized services, intelligent e-textiles make for a more enjoyable and convenient interaction experience for the wearer. For example, in the field of entertainment performances, smart clothing can provide users with an immersive performance experience by combining with virtual reality technology to achieve real-time interaction with the audience. (2) Comprehensively consider the composition technology of interactive e-textiles with different functions to improve their stability, usability, and multifunctional integration. Although advances in nanotechnology and fabrication methods have dramatically impacted large-area flexible and stretchable intelligent e-textiles for electronic information, challenges remain in achieving fully integrated and efficient intelligence performance. New challenges are posed for effectively embedding electronic functions into textiles and maintaining their comfort and durability. (3) Optimize the performance of intelligent interactive materials and improve the efficiency of the production process to reduce the production cost of interactive e-textiles. Although cost remains a significant constraint on developing sensory interactive e-textiles in the short term, this issue is expected to be resolved in the long term as technology advances and the market grows. (4) The concern for privacy security is increasing nowadays, and the ability of interactive e-textiles to track, store, and transmit user information raises concerns about data security and privacy issues. Future research focuses on guaranteeing users’ privacy and security when using them.

Responses