On-fiber photonic nanojet enables super-resolution in en face optical coherence tomography and scattering nanoscopy

Introduction

The pursuit of sub-diffraction confinement of light and power concentration has been a longstanding focus of research, dating back to the early predictions of optical resolution and the diffraction limit. It is still a challenge as the application of optics, especially in nano-domain, is experiencing a significant progress even beyond optical imaging. In this context, the optical confinement of an instrument in the far-field is guided by Abbe-Rayleigh’s criteria. According to the criteria, the resolution of an optical sensing instrument is limited by the spot-size of the optical beam, analogous to uncertainty principle in quantum mechanics1,2,3. It is incapable of resolving higher frequencies responsible for the object sharpness because of the diffraction limit. Consequently, the wave optics restricts this limit to λ/(2NA)1 for an objective lens, where NA stands for numerical aperture of the lens and λ represents the illuminating wavelength. A more practical approach to this resolution limit is defined in terms of full width at half maximum (FWHM) or spot-size, ω = (0.51λ)/NA, which is approximately equal to Abbe’s definition. FWHM serves as a key parameter for evaluating the optical confinement and optical resolution because it is relatively easy to measure and widely accepted. The ability to visualize objects in nano-scale through imaging or spectroscopy relies on the optical beam’s spot-size being compressed beyond the classical diffraction limit.

Alternately, the near-field approach offers an intriguing perspective by utilizing non-propagating evanescent waves to surpass the diffraction limit. However, the non-propagating evanescent waves, characterized by ~e-kz, contain subwavelength information but they are confined solely to the surface4. Thus, probing the evanescent wave is quite difficult due to its rapid decay unlike far-field diffraction, demanding complex mechanical and optical arrangements. Moreover, it is limited by practically zero working distance and an extremely small depth of field. Despite these challenges, the last decades have seen several breakthroughs in imaging techniques that have gone beyond the diffraction limit5,6,7,8,9. Therefore, a simple far-field optics approach with sub diffraction confinement can be highly valuable for photonics application and a photonic nanojet (PNJ)10 with subwavelength spot-size is found to be an ideal tool in this regard.

The phenomenon of PNJ is a non-resonant and non-evanescent by nature. It can be explained by Mie’s theory of scattering, which predicts the field enhancement by microspheres transforming from the Rayleigh scattering regime (r ≪ λ) to a jet-like regime in mesoscale spheres (r∼λ − 30λ)11,12. Depending on the excitation conditions, it can either confine the light inside the cavity, forming WGMs or focus the light in proximity to the shadow side, resulting in the formation of PNJ. The localized PNJ forms along the line of incidence at the shadow-side surface of the microsphere and exhibits the non-diffracting characteristics of light over a distance of several wavelengths with a sub-wavelength spot-size13,14. This can be possible due to the interference between incident light and scattered light.

Since its introduction, PNJ has provided an immense impact on super-resolution optical imaging10,15,16 fluorescence spectroscopy17, enhancement of Raman scattering18,19, nanoparticles sensing20,21,22, nanolithography23,24, and many others25 due to the backscattering enhancement26 and sub-diffraction field confinement. The further development and application of photonic nanojets could provide useful new approaches for conducting inverse-scattering studies of weakly contrasting micron-scale material objects. As of now, the microsphere needs to be hold by a cantilever27/capillary28/optical tweezer29/PDMS film30 and the illumination is provided by the microscopic objective for line-of-sight imaging majorly in contact mode. While for the sensing applications optical fiber based excitation of photonic nanojets has been reported by temporary tweezing21,22, the imaging aspect of this simple approach using low coherence interferometry is still untouched despite of the fact that it can provide the lateral resolution improvement upto one third of the spot size31. To access the full potential of this approach in sensing as well as imaging there is a need of a standalone PNJ head especially if it can be designed at an optical fiber tip. The ability of PNJs to move freely can open the numerous horizons of application assisted with the waveguide nature of the optical fiber.

In this letter, a standalone PNJ head is developed at the tip of an optical fiber. It consists of a nanoprobe located within the cavity of an optical fiber tip fabricated using a one-step chemical etching process. The nanoprobe generates a focused optical beam with a tight spot-size of ~2 µm. The cavity in front of the nanoprobe holds a microsphere, and thus the optical beam from the nanoprobe can be focused on the microsphere, resulting in a quality PNJ. The proposed PNJ head is free to move and suitable for use in both reflection and transmission mode. As an application of this standalone PNJ head, we have demonstrated an OCT resulting in a super resolution en face image beyond the spot-size (ω) restricted diffraction limit, <ω, as well as sub diffraction scattered light field imaging of nano-particles as revealed in the sections below.

Methods

Materials

The Barium titanate microspheres of diameter 5 µm–50 µm were brought from sigma-aldrich, 48% hydrofluoric (HF) acid from Merck and the GF3 optical fiber from Coherent.

Nanoprobe fabrication

The encaved nanoprobe is fabricated through chemical etching of a highly germanium doped optical fiber (GF3) using 48% HF. Initially, the optical fiber is stripped, cleaned and cleaved before being vertically immersed in HF acid contained within a plastic tube, with a protective layer of toluene placed above the HF. The higher doping concentration in the core results in a faster etching rate compared to the cladding, leading to upward etching from the facet of the optical fiber. This upward etching forms a conical cavity along the core-cladding boundary with the apex located at the core, and a conical tip in the core at the center of the apex due its refractive index profile. The formation of conical tip in the core can be explained by the fact that there is a defect due to non-uniform material distribution at the center of the core of the optical fiber along the optical axis. The circular defect has diameter ~2 μm as observed from the optical microscopic image of the fiber tip, as shown in the Supplementary Fig. 1. This results in mismatch in etching rate of the optical fiber materials at the fiber cladding, core and the very center of the core in HF solution. The part of the core surrounding the defect zone has higher etching rate due to higher Ge concentration compared to the cladding and the center of the core. The said mismatch develops a conical nanoprobe around the optical axis with base diameter <2 μm and height ~1 μm at the center surrounded by the cavity as soon as one dips the optical fiber in HF solution32. The conical nanoprobe is recreated dynamically and the shape remains constant as long as etching continues except varying the length of the cavity. The technique is introduced recently to develop encaved nanoprobe at optical fiber tip33. The cavity length can be precisely controlled by etching time, while the conical tip structure remains unaltered. Upon reaching the desired etching time, the optical fiber is removed from the HF and rinsed in a stream of deionized (DI) water followed by annealing to evaporate any trapped water from the cavity. In our experiments, we have used the PNJ probe with a 3 min etching time, resulting in a cavity length of ~17 µm and opening diameter of ~19 µm. The nanoprobe is fabricated inside the optical fiber tip as observed in Fig. 1b (field emission scanning electron microscope (FESEM) image of the cavity). The recent development of the optical fiber nanoprobe is a well-known fact for its maturity, interesting optics and application33,34,35,36,37.

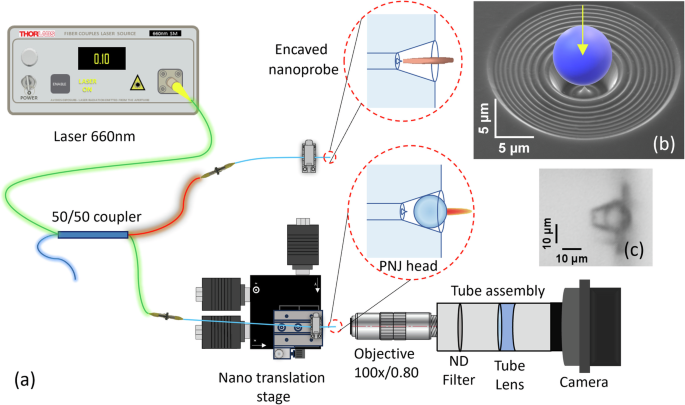

a The 660 nm laser source is coupled to a 50/50 coupler whose one output arm (orange branch) holds the nanoprobe while another (green branch with Nano translation) holds the PNJ head. The coupler assures the same power goes to both the arms while profiling the respective beam using custom made near field beam profiler consisting of an objective, tube assembly and CMOS camera. b shows a Field Emission Scanning Electron Microscopy (FESEM) image of the nanoprobe to demonstrate that how a microsphere is placed inside the cavity of the nanoprobe and (c) shows an optical microscopic image of PNJ head.

Microsphere integration

The microspheres are scattered onto a glass slide under a calibrated stereo microscope equipped with a camera. A microsphere of the desired diameter is then selected and picked up electrostatically on the tip of a tapered optical fiber mounted on a 5 axis-manual translation stage. Subsequently, the optical fiber carrying the microsphere is aligned with the encaved nanoprobe which is mounted on another 5-axis manual translation stage. Finally, the microsphere is meticulously positioned and pushed inside the cavity, and then we drag out the tapered tip fiber sidewise leaving the particle in the cavity. A pictorial representation is shown in Fig. 1b to elaborate how a microsphere is placed inside the cavity of the nanoprobe. Additionally, an optical microscopic image of a standalone PNJ head is showcased in Fig. 1c.

Beam profiling

For PNJ beam profiling we have used a home-made near field beam profiler comprising a 100×/0.8 NA infinity corrected apochromatic objective lens integrated into a tube assembly along with a neutral density (ND) filter, a 200 mm tube lens and a 20MP CMOS camera. Figure 1a depicts the schematic of the experimental setup to capture the PNJ as well as the nanoprobe beam profiles in air. The setup is calibrated with a USAF 1951 resolution target. A 660 nm fiberized benchtop laser from Thorlabs is employed as a source for this experiment. The light is guided through a 670 nm, single mode fused optical fiber 50–50 coupler to two output arms: an encaved nanoprobe (S1) and a PNJ probe (S2). The beam profiling of both the sample probes S1 & S2 is carried out one by one at the same input power for intensity enhancement comparison.

The sample is mounted on a tilt stage which in turn is fixed on 3-axis nanoMAX from Thorlabs. Throughout the experiment, the beam profiler is kept stationary while the sample undergoes translational motion. Initially, the beam profiler is focused on the facet of the nanoprobe to mark the reference position. Consequently, the focus is then shifted inside the cavity upto the measured cavity length to begin the profiling. The focus is then translated in the direction of beam propagation with the step size of 60 nm and an image is captured at each step over a total length of 22 µm. Furthermore, these images are stacked to construct a 3D beam profile using Fiji38 and a plane along the direction of propagation is extracted to show 2D beam profile in longitudinal direction.

As the nanojet is ready, the PNJ head is used as a probe to scan a DVD surface to examine performance of the nanojet as an interferometric en face OCT probe with sub-diffraction resolution including phase imaging. Further, the probe is tested for scattering nanoscopy by scanning silver nanoparticles on a glass slide.

Enface OCT imaging and phase imaging processing

We have used the similar setup as briefly described in our earlier work39, with the only difference in the sample placement, the imaging sample is now mounted vertically, while the PNJ probe is kept horizontal (Supplementary Fig. 2). A standard Fourier transform algorithm is used for en face OCT imaging. For phase imaging, a Fourier transform based phase retrieval algorithm is applied in spectral-domain40. The desired phase, ϕ(z) in terms of optical path length, (Delta L(z)) as a function of depth, z is estimated using Eq. (1).

Results & Discussion

PNJ simulation results

The simulations are performed using COMSOL to evaluate the background of the prospective PNJ before conducting experimental investigation. Figure 2a, b shows the simulated and experimental beam profile respectively in a longitudinal plane through the optical axis radiating from the nanoprobe. The nanoprobe generates zeroth order Bessel-Gauss beam characterized with a prominent central lobe having spot-size of ~2 μm at ~14 μm distance from the probe tip.

a COMSOL simulation of the optics from nanoprobe inside the optical fiber tip cavity. b Experimentally obtained beam profile from a nanoprobe in a longitudinal plane through the beam axis, the linescan along the central axis(horizontal red line) indicates variation in intensity with propagation, the inset is the transverse beam profile taken across the vertical red dashed line. It shares the same scale of figure (b) itself. c Represents an intensity comparison of the simulation results between the nanoprobe beam and PNJ, longitudinally along the optical axis. The blue circle shows the position and outline of microsphere. d COMSOL simulation of the PNJ from the microsphere placed at the opening of the cavity in front of the nanoprobe. Both the figure (c, d) are concatenated and shares the same X axis. This helps to understand how the field varies relative to the position of nanoprobe and microsphere.

For PNJ generation, a microsphere of diameter 12 μm is strategically placed at ~3 μm from the probe tip. The diameter and location of the microsphere are selected to ensure that the central spot of the Bessel-Gauss beam having higher intensity converges at the vicinity of the distal end of the microsphere, as presented in Fig. 2d, a prerequisite condition for PNJ generation11.

The simulation is performed for the wavelength, λ = 660 nm and the spot-size of the simulated PNJ is obtained as ~0.5λ. Subsequently, the intensity of the PNJ formed at the shadow side of the microsphere is compared in Fig. 2c with the intensity of the beam generated solely by the nanoprobe. It is observed that the intensity of the PNJ experiences ~1.75 times increase in the field intensity in comparison to the nanoprobe beam.

Characterization of the PNJ

Figure 3 demonstrates a comprehensive overview of the experimental results related to the PNJ. Figure 3a, b, present side view and front view of the PNJ head respectively. Figure 3c, d showcase the beam characteristics of the PNJ captured by a homemade beam profiler with 100×/0.80 dry microscopic objective. The profiler setup is configured for a 660 nm source coupled to the nanoprobe fiber as schematically shown in Fig. 1a. The 3D beam profile of the PNJ at the plane of the highest intensity is represented in Fig. 3d. However, the evolution of the PNJ along its length is illustrated in 3D animation (Supplementary Movie). The nanojet originates inside the microsphere and extends to ~8 μm, (13λ) beyond the microsphere surface.

a Top view optical microscopic image of cavity with nanoprobe holding a microsphere, ~13 μm diameter as PNJ head. b Front view of the microsphere placed at the cavity opening and near to the nanoprobe. c Beam profiling of photonic nanojet from the microsphere, the white curve indicates microsphere’s boundary. d 3D beam-profile of the nano-jet taken at a selective transverse plane with highest intensity in the PNJ from (c). e Variation in the spot-size, ω over the length of the PNJ. The yellow shaded area lies inside the microsphere. f Transverse beam profiles of the beam from nanoprobe (red triangles) and PNJ (blue solid square) at the plane of the highest intensity.

Figure 3e depicts the variation of the spot-size (ω) of the PNJ across its entire length, ranging from a maximum, ω ~ 550 nm (0.8λ) to a minimum, ω ~ 300 nm (0.5λ). The experimentally attained minimum spot-size, ~0.5λ matches with the spot-size obtained in the PNJ simulated results. The colored half of Fig. 3e corresponds to the region within the microsphere, while the remaining part represents the region outside the microsphere. This visualization is generated by tracing the beam as the beam profiler initially focuses inside the microsphere, while the PNJ head placed on nano-stage is slowly moved away by 60 nm step-size. The transverse beam profiles of the PNJ and nanoprobe at the plane of maximum intensity are compared, as illustrated in Fig. 3f. It is evident from the experimental results that the PNJ experiences ~1.5-fold increase in the intensity, which is in accordance to the simulation result. However, a focal shift in the PNJ can be observed between the simulation and experimental result whereas the length of the PNJ closely matches. The mismatch in 2D simulation and 3D experimental results may be due to approximation in the material property of the microsphere and geometry of nanoantenna used in the simulation, including non-ideal geometry of the microsphere used in the experiment in terms of non- sphericity. Moreover, the PNJ exhibits a tighter spot-size and more importantly, it is free from any significant sidelobes.

En face Optical Coherence Tomography (OCT) and Phase imaging

As an application of the state-of-the-art tool, an imaging experiment is performed for super-resolution en face OCT imaging including phase imaging and results are discussed in the following section. A common-path OCT experimental arrangement has been employed for the imaging (Supplementary Fig. 2). For the PNJ beam profiling, a 660 nm monochromatic laser source is used whereas en face OCT requires broad band source. Accordingly, a source with bandwidth ~50 nm centered at 840 nm, usually recommended for OCT, is used for the nanoscopy imaging.

A highly reflective DVD as a sample, positioned vertically from 3 μm to 4 μm away on a translational nano-stage in front of the PNJ head. The sample is then scanned over an area of 10 μm × 5 μm in the transverse plane with a step size of 60 nm for each scan. The optical fiber tip is placed in the V-groove in an optical fiber holder to assure its alignment. Also, the working distance between the microsphere and the sample is several micrometers unlike many scanning devices with nanometer working distance. Therefore, small misalignment may not be an issue unless we scan a very big area in one go. En face image of the DVD sample from the common-path OCT system with SNR ~42 dB is displayed in Fig. 4d. Whereas, Fig. 4a,e present the en face and phase image of the DVD with an area of 3 μm × 2 μm which is the region marked by yellow rectangular box in Fig. 4d. Figure 4c is the microscopic image of the DVD taken under 100× objective with numerical aperture 1.25 in oil which is in close match to the Fig. 4a obtained from the proposed system. A line scan along the yellow line from the en face OCT image is concatenated with the image sharing the same horizontal scale in Fig. 4a. The line scan reveals that the proposed OCT system can achieve sub-diffraction resolution, ~247 nm. The resolution is also confirmed by the supporting FESEM image of the same DVD sample, as shown in Fig. 4b. Further, the 3D phase image of the DVD provides an optical thickness of ~70 nm as indicated by the colorbar in Fig. 4e.

a An en face OCT image of DVD: (i) The DVD grating shows a resolution ~246 nm, ~0.3 times the wavelength used in the experiment, the dimension of scale bar is 500 nm. The concatenated graph (ii) shows a linescan of the OCT image at position marked by yellow line. b FESEM image of the said DVD with gold coating predicts a resolution ~246 nm confirming the OCT resolution. c 100× microscopic image of the DVD sample taken with 1.25 NA objective in oil, the dimension of scale bar is 500 nm. d A larger area En face OCT image of the DVD, yellow box highlights panel (a(i)), the scalebar is 1 μm. e 3D phase image of the DVD sample with a colorbar representing the optical thickness, ~70 nm.

The imaging resolution provided by PNJ in air is equivalent to the standard optical microscopic system having numerical aperture of 2.07 (Rayleigh criteria) and 1.7 (Abbe’s criteria). Notably, the obtained resolution is comparable to the standard fluorescence system, such as a confocal microscope, where the lateral resolution is limited to around 200 to 250 nm41. Additionally, there is a possibility of achieving even better resolution as evidenced by the experimental results yielding fully resolved image with a resolution of 247 nm.

The en face provides the efficient surface analysis with high resolution and depth profile. The finest spatial resolution achieved by en face OCT is ∼0.7 μm in time domain42. Scholler et al. has showcased a multimodal OCT having ∼1.7 μm and ∼0.4 μm, i.e., 2.02λ and 0.6λ lateral resolution at 840 nm and 660 nm wavelength, respectively43. The en face OCT system usually achieves lateral resolutions down to ~1–2 µm44,45,46,47. However, by providing a resolution of 0.24 μm i.e., 0.29λ the proposed system outperforms the existing literature in terms of lateral resolution.

PNJ Scattering Nanoscopy

PNJ is highly effective in enhancing back-scattering when a nano object enters the nanojet which could be beneficial for fluorescence and Raman spectroscopy applications without surface modification. The enhancement factor of the proposed PNJ has been tested using a single grating of the DVD as scatterer. The PNJ head is scanned across and away from the grating using the similar experimental arrangement. Figure 5a plots the back-scattered field as a function of longitudinal distance. It is observed that the back scattered field for ~250 nm scatterer placed within 4 μm to 5 μm from the microsphere is enhanced by ~10 fold due to the nanojet. Beyond the nanojet, the scattered field sharply drops. A second, but weaker enhancement peak is observed, which may be due to the intense light at the focal length (~8 μm) of the microsphere acting as a ball lens. Although beam profiling is not repeated for 840 nm source, the ~10 times back scattering enhancement, Fig. 5a, indicates that the design also gives PNJ at 840 nm wavelength which is further confirmed by the simulation result, (Supplementary Fig. 3). The same source is again used for silver nano-rods characterization in reflection mode due to the already available experimental setup.

a Enhancement of the PNJ optical field as the probe is gradually scanned away from DVD line grating as the scatterer. Inset is the scattered field intensity mapped image of the grating lines, scale bar indicated 500 nm. b Intensity mapping of the back scattering of silver nano-particle samples, drop casted on a glass slide, ranging from 35 nm to 150 nm, using the same PNJ head. Supplementary Fig. 4 shows a SEM image of the silver nanoparticles resembling the scattering results (b). The sample is prepared by drop casting of diluted silver nano-particle solution.

To assess the PNJ head’s capacity to capture scattering light from a scatterer, we have done point by point intensity mapping of the DVD nanostructure and silver nano-particles (35 nm-150 nm) drop-casted on a glass slide using the same experimental setup as in case of enface OCT imaging. The intensity value is obtained by integrating the spectrum recorded at a point. Figure 5a-inset shows the intensity mapped image of DVD where the grating structure can be seen. The result presented in Fig. 5b show that the PNJ can detect silver nano-particles, as small as ~40 nm by mapping the intensity of the back-scattered field from the particles. This suffice the fact that the PNJ may also be suitable for Raman, and fluorescence spectroscopy.

Further, it may be mentioned that the length of photonic nanojet can be improved by truncating the microsphere (Supplementary Fig. 5). In the long term, the PNJ head holds great promise for optical imaging, nanolithography, optical trapping etc. and also generating complex photonic hook48 (Supplementary Fig. 6).

Conclusion

In summary, we have introduced a state-of-the-art standalone photonic nanojet head at optical fiber tip capable of generating long range, ~13λ, nanojet with subwavelength spot-size, 0.5λ. It can be useful in remote sensing application, demanding sub-diffraction resolution. As a proof, optical coherence en face and phase imaging are performed on standard DVD. The experimental results show the sub-diffraction spatial resolution of ~247 nm (0.29 λ) with a 42 dB SNR and ~70 nm optical thickness for ~840 nm illumination. Our imaging system offers the resolution equivalent to a numerical aperture of 2.074 in a standard optical microscopic system. Additionally, the intensity mapping of silver nano-particle as light scatterer with an achieved detection capacity of ~40 nm suggests the PNJ head will also be ideal for high-resolution fluorescence, and light-scattering microscopy application. Another significant advantage is the repeatability and reproducibility of the PNJ head, as the natural chemical process ensures the cavity and the nanoprobe fabrication as long as a proper optical fiber is chosen.

Responses