Advanced manufacturing technologies, strategic agility, business network and sustained competitive performance: an empirical evidence from an emerging economy

Introduction

Digital manufacturing plays a crucial role in the manufacturing industry as it allows organizations to create highly customized, digitalized products of superior in a shorter time frame compared to traditional methods. Further, digital manufacturing has the capacity to enhance the visibility of data in real-time and produce extensive datasets regarding manufacturing processes, which serves as the foundation for successful partnership, optimization, design, and analysis in the entire firm operations (AlNuaimi et al., 2022). From this standpoint, Li et al. (2020) and Wong and Ngai (2023) stated that advanced manufacturing technologies allow manufacturers to integrate the cost advantage of economies of scale and the adaptability of economies of scope to build sustained competitive advantage. Several advantages of advanced manufacturing technologies over traditional manufacturing include its capacity to distribute processing tasks, resulting in faster production, less waste, and improved control over processes (Wong and Ngai, 2023). Altogether, it seems that advanced manufacturing technologies enable faster adjustments to the design of products and consumer demand, providing a high level of flexibility.

Research indicates that a substantial amount of sustained success of enterprises in industrialized countries arises from technological advancement. So, there is a need to examine strategies firms in emerging economies can adopt to use advanced manufacturing technologies to succeed effectively. In the current literature, extensive research on advanced manufacturing technologies focuses on industrialized countries (Boyer et al., 1997; Ford and Despeisse, 2016). However, recently, research shows that several emerging economies have made significant progress in digital manufacturing (Luthra et al., 2020; Sharma et al., 2021). Hence, research on advanced manufacturing technologies in emerging economies is crucial for gaining insights into the dynamics of industrialization for firms in emerging economies (Sharma et al., 2021; Wong and Ngai, 2023) and advancing the theories established and tested for enterprises in industrialized countries (Ali, 2021).

Advanced manufacturing technologies provide numerous benefits in versatility, quality, and delivery compared to conventional techniques (Parmar et al., 2022). Moreover, it is anticipated that in the future, advanced manufacturing technologies will efficiently and economically manufacture numerous products in small lots using a paperless and labor-free procedure (Bag et al., 2021; Parmar et al., 2022). However, these new manufacturing characteristics offer new opportunities and challenges for industry and academia. Although some research has been conducted in this area, the question of how advanced manufacturing technologies translate into a sustained competitive advantage in emerging economies, remains unclear. Thus, it is important to explore how and the conditions under which advanced manufacturing technologies lead to sustained competitive advantage.

Aside from these, strategic agility is another issue that has become a topic of great interest among researchers and is considered crucial for business success (Kale et al., 2019; Mata et al., 2023; Tallon and Pinsonneault, 2011). Being agile allows businesses to respond quickly to changes, remain flexible, adapt to new circumstances, and take other measures to manage market uncertainty and risk (Mata et al., 2023). Strategic agility is the continuous maintenance of management perception, flexibility, forecasting, and strategic sensitivity toward internal and external environments (Kumkale, 2016). Agility allows a firm to adjust and keep up with market changes, quickly gather information, take advantage of them, and customize its products (Sherehiy et al., 2007) toward achieving sustainable competitive advantage. Moreover, such changes can be transformed into opportunities when strategies and systems are restructured in response to environmental changes (Shin et al., 2015).

Analyzing studies on agility, it seems that while certain studies have focused on the importance of agility in the manufacturing industry (e.g., Singh Patel et al., 2020; Theyel and Hofmann, 2021), strategic agility has received little attention in the current literature. Moreover, identifying advanced manufacturing technologies as a dynamic capability presents intriguing research avenues. Amid the current organizational transformation, competitive advantages are becoming increasingly important due to several factors, such as innovation, industrial trends, and technology (Galvin et al., 2020). Hence, strategic agility serves to detect changes in the business environment and allows firms to respond to them (Mata et al., 2023). Although advanced manufacturing technologies may significantly predict sustained competitive advantage, this relationship can be more robust when bridged through strategic agility.

Further, the emerging literature demonstrates the relationship between advanced manufacturing technologies and sustained competitive advantage (Wong and Ngai, 2023). However, the nature of this relationship may differ when examined in different countries, particularly in emerging economies. In addition, the current literature scarcely discusses how the relationship develops. Strategic agility is needed when competing and satisfying consumer changing needs (Gehani, 1995). Thus, strategic agility is among the most crucial potential mechanisms that may be used to explain better the relationship between advanced manufacturing technologies and sustained competitive advantage. Despite this, limited research has examined advanced manufacturing technology, strategic agility, and sustained competitive advantage.

Further, while advanced manufacturing technologies allow firms to integrate cost advantage measures to build sustained competitive advantage, this is more likely to happen when manufacturers are embedded in relationship networks. Such networks not only offer particular resources, but also promote assistance and mutual reliance for value co-creation (Zang et al., 2022). Generally, since firms in emerging economies such as Türkiye cannot autonomously innovate, it becomes a challenge for them to cope in an ever-changing competitive environment with their capabilities and resources (Mei and Zhang, 2022), making it difficult to achieve sustained competitive advantage.

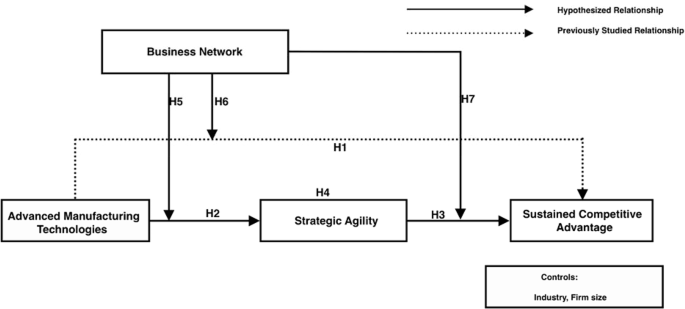

The dynamic capabilities theory (Teece et al., 1997) and institutional theory (Li and Atuahene-Gima, 2001) propose that firms’ activities are heavily influenced by their specific environment, and obtaining external institutional support is crucial in ensuring their development and success. Hinging on these theories, this study argues that it is crucial to investigate the moderating role of business networks on relationships from an emerging economy perspective. The study’s model was examined (see Fig. 1) using a sample obtained from Turkish manufacturing firms across various industries in an emerging economy. The study aims to offer answers to the following research questions:

-

1.

Do advanced manufacturing technologies influence sustained competitive advantage?

-

2.

Does strategic agility mediate the relationship between advanced manufacturing technologies and sustained competitive advantage?

-

3.

Does a business network strengthen the relationship between advanced manufacturing technology, strategic agility, and sustained competitive advantage?

Source: authors compilations.

Altogether, this research provides a new perspective to a more comprehensive understanding of advanced manufacturing technologies and sustained competitive advantage from an emerging economy perspective. This study advances the understanding of the relationship between advanced manufacturing technologies, strategic agility, and sustained competitive advantage through the lens of dynamic capabilities and institutional theory. The emerging literature suggests advanced manufacturing technologies trigger sustained competitive advantage (Wong and Ngai, 2023); however, little is known about how this relationship develops. This study uncovers strategic agility as a mediating mechanism through which advanced manufacturing technologies improve sustained competitive advantage, filling the void in the current literature.

Further, the conditions under which advanced manufacturing technologies lead to sustained competitive advantage remain unclear. In an uncertain external environment, firms encounter rapid changes in production technologies, customer demands, and market competition (Wang et al., 2020). Through business networks, firms can build cooperation relationships to obtain crucial resources such as the latest production technologies necessary for development and to achieve success. This study uncovers business networks as a crucial factor that could either strengthen or weaken the relationships in our model. Lastly, this research offers practical guidance on how firms can navigate competitive challenges and reveal the conditions necessary to promote their competitiveness to succeed in emerging economies such as Türkiye.

Literature review

The relevance and foundation of advanced manufacturing technologies, strategic agility, business networks, and sustained competitive advantage can be linked to different theories. However, this research draws from two of the most prominent theories in operations and strategic management. The theories are dynamic capabilities theory and institutional theory.

Theoretical framework

The dynamic capability theory acknowledges that as situations evolve, the emergence of new configurations that are more beneficial would gain favor while the potency of existing resources will disappear (Teece et al., 1997). The dynamic capability view proposes that the overall performance of an enterprise is contingent upon its ability to adapt, recognize, and redefine itself. Scholars have adopted the dynamic capability theory to explain organizational change processes in various aspects, such as innovation, technological advancement, firm transformation, and entrepreneurial behavior (Al Tera et al., 2024; Ciampi et al., 2021; Soluk and Kammerlander, 2021; Teece, 2016; Valdez-Juárez and Castillo-Vergara, 2021). The dynamic capability view was developed as the theoretical basis for understanding how routine adaptation processes are specified (Teece, 2007). The theory is designed to demonstrate how firms can adapt, compete, and survive in a fast-evolving business context (Teece et al., 1997). Dynamic capability emerged after introducing the resource-based view (Barney, 1991).

According to the resource-based view, firms need ‘valuable, unusual and hard to replicate or substitute’ intangible and tangible assets to compete successfully. However, the dynamic capability theorists stated that ambitious firms may need to reconfigure resources swiftly and respond to challenges in highly dynamic environments (Teece et al., 1997). The primary focus of dynamic capabilities is embedded in firm routines and business processes. From this standpoint, early empirical research highlighted the significance of dynamic capabilities in nurturing innovation and attaining competitive advantage (Eisenhardt and Martin, 2000; Helfat and Peteraf, 2009). Although these studies provide insights into the importance of dynamic capabilities, there remain gaps regarding the deployment and manifestation within the distinctive context of manufacturing firms in emerging economies integrating disruptive manufacturing technologies.

Another theory is the institutional theory, which is well-recognized in organizational studies. This theory covers a wide range of theoretical and empirical insights highlighting the relevance of firm culture and change (e.g., Chen et al., 2020). However, the new institutional theory discusses how firms interact with their environments to thrive and succeed in the face of challenges and competition (Li and Atuahene-Gima, 2001). The new institutional theory describes how firms’ operations are rooted in a unique institutional context and that external institutional support is crucial to their continued success (Li and Atuahene-Gima, 2001). Based on this, emerging studies use the new institutional theory to comprehend organizational transformation related to implementing advanced technologies by exploring external contingencies on firm practices (AlNuaimi et al., 2022; Dubey et al., 2019). This research aims to rely on the above theories to provide new insights into how and the conditions under which advanced manufacturing technologies can be used to develop sustained competitive advantage from the perspective of an emerging economy.

Advanced manufacturing technologies

Advanced manufacturing technologies are often described as tools that streamline and automate product design, planning, control, and manufacturing processes (Boyer et al., 1997; Swink and Nair, 2007). Using computer applications for processing data on an organization’s manufacturing operations is a crucial element of advanced manufacturing technologies (Wong and Ngai, 2023). Advanced manufacturing technologies are often associated with manufacturing process technologies that rely on computers for data exchange, manipulation, and storage (Cagliano and Spina, 2000; Krar and Gill, 2003). In this study, advanced manufacturing technologies are associated with various technologies such as computer-aided manufacturing, artificial intelligence, computerized numerical control, flexible manufacturing systems, and others that heavily rely on computers to oversee, manage, and monitor manufacturing operations, both directly and indirectly (Boyer et al., 1997; Wong and Ngai, 2023).

Previous studies have emphasized the need for firms to invest in advanced manufacturing technologies to enhance overall efficiency (e.g., Kong et al., 2016). Based on this, research has demonstrated the advantages of advanced manufacturing technologies, such as improved delivery, flexibility, lower costs, productivity, market share, and competitive advantage(Cagliano and Spina, 2000; Swink and Nair, 2007). Recently, researchers have also argued that advanced manufacturing technologies are a source of innovation in relation to planning, design, and manufacturing processes (Bag et al., 2021). Surprisingly, empirical evidence relating to how and the conditions under which advanced manufacturing technologies improve the sustained competitive advantage of firms is limited, particularly from the perspective of emerging economies. When implementing competitive strategies, manufacturing firms are open to learning about how advanced manufacturing technologies translate into sustained competitive advantage (Wong and Ngai, 2023).

Perhaps, insufficient insights into how to use advanced manufacturing technologies to build sustained competitive advantage may hinder the establishing framework that represents and depicts the activities of manufacturing firms. While integrating advanced manufacturing technologies could promote sustained competitive advantage, strategic agility may mediate this relationship. Hence, examining the mediating role of strategic agility in this relationship is crucial. Further, Ahsan et al. (2021) contend that external environmental factors such as business networks should be considered, particularly for firms operating in emerging economies; thus, it is crucial to determine the extent to which business networks influence the relationship between advanced manufacturing technologies, strategic agility and sustained competitive advantage.

Sustained competitive advantage

Banmairuroy et al. (2022) stated that sustained competitive advantage is another important issue for firms to consider during the industrial revolution period. From this standpoint, two distinct forms of competitive advantage were discussed. One is a temporary competitive advantage that generally leads to substantial profits but has limited longevity. The second is sustained competitive advantage, which is achieved when competitors cannot imitate the source of competitive advantage (Barney and Hesterly, 2019). This study focuses on the latter. According to Barney (1991), sustained competitive advantage is described as follows: a sustained competitive is said to be achieved by a firm when it implements a strategy that creates value, and any potential or current competitors are not using it, and the inability of the competitors to replicate the benefits of the strategy.

Using the dynamic capabilities theory, Wong and Ngai (2023) demonstrated that the firm’s resources with specific qualities of rareness, value, and imitability are crucial for developing sustained competitive advantage. Further, Barney (2007) discovered that sustained competitive advantage could help firms smoothly run business operations in the constantly evolving technology life cycle. Thus, in today’s dynamic business environment, achieving sustained competitive advantage is crucial for firms in emerging economies.

Advanced manufacturing technologies and sustained competitive advantage

Generally, Gillani et al. (2020) stated that digital manufacturing technologies convert conventional factories into smart factories by applying the principles of computing, connectivity, and automation. Based on this, some authors found that digital manufacturing technologies promote customization, flexibility, productivity, cost-effectiveness, and efficiency (Kumar et al., 2021). More specifically, advanced manufacturing technologies are a form of digital manufacturing technologies. Research also found that advanced manufacturing technologies facilitate low-cost differentiation techniques (Kotha and Swamidass, 2000; Pu et al., 2021) by improving manufacturing functions such as the development of the products, logistics planning and information interchange, and manufacturing process (Kotha and Swamidass, 2000). Mainly, design-based advanced manufacturing technologies such as the integration of artificial intelligence computer-powered design can shorten the design cycles and time-to-market, minimizing design costs (Wong and Ngai, 2023).

Similarly, product data management (PDM) systems store and analyze information on product structures, product development projects, documents, and quality; this information can be used to enhance the product development function. It helps manufacturers during the design and refining stages and generates data-driven reports (Kropsu‐Vehkapera et al., 2009). Further, emerging technologies such as additive manufacturing facilitate the generation of swift prototyping with high-precision product information, shortening product development cycles (Holmström et al., 2019). Manufacturers can rapidly produce large quantities of serialized products with scalable additive manufacturing. This technology streamlines the initiation of various manufacturing techniques by eliminating unnecessary production steps, minimizing raw material usage, and improving customer response times (Roscoe et al., 2019).

Furthermore, organizations strive to maintain market share, improve manufacturing operations, and ensure cost-effectiveness to survive today’s competitive environment (Samson and Swink, 2023; Wong and Ngai, 2023). To achieve this, Wong and Ngai (2023) argue that advanced manufacturing technologies such as robotics, artificial intelligence, computer-controlled systems, group technology, and flexible manufacturing can transform and switch firm emphasis from economies of scale to economies of scope.

Despite the critical role of advanced manufacturing technologies in firms’ survival (Kumar et al., 2021; Holmström et al., 2019; Pu et al., 2021), little is known regarding the impact of advanced manufacturing technologies in emerging economies. While researchers have started to examine the impact of advanced manufacturing technologies on sustained competitive advantage (e.g., Wong and Ngai, 2023), there is still limited research on the drivers of sustained competitive advantage in the manufacturing industries from an emerging economic perspective in response to disruptive manufacturing technologies. Thus, in advancing the current literature from an emerging economy perspective, this study posits that:

H1: Advanced manufacturing technologies have a positive effect on sustained competitive advantage.

Advanced manufacturing technologies and strategic agility

Strategic agility is an important construct in operations management research. Strategic agility relates to the capacity to consistently adjust business strategic directions by developing new business models, new products, and innovative methods of creating value (Lin et al., 2010). In addition, strategic agility is the capacity to identify and respond to changes that can enhance organizational success through capitalizing on potential opportunities, generating new sources of sustainable competitive advantage, and building the essential capability for survival (Felipe et al., 2016). Therefore, to fulfill strategic objectives, firms must consistently anticipate, adapt to, and engage with market changes and consumer demands (Saha et al., 2017). To meet consumer demand for customized, cost-effective, and high-quality products, manufacturers must improve their manufacturing processes and use new technologies (Horváth and Szabó, 2019).

From the dynamic capabilities perspective, to survive in today’s competitive environment, manufacturing firms must develop sensing, seizing, and reconfiguring capabilities (Wong and Ngai, 2023). The capabilities mentioned are crucial if manufacturing firms sustain themselves longer. Manufacturing firms equipped with strong advanced manufacturing capabilities are in a position to improve their strategic agility—that is, a firm’s continuous ability to adapt and adjust its strategic orientations in its fundamental operations to generate value (Doz and Kosonen, 2010). Despite this, the extant literature is silent on the relationship between advanced manufacturing technologies and strategic agility. The current literature has not explicitly examined this relationship.

Computer-aided process planning (CAPP) and computer-aided manufacturing (CAM) integrate user preferences into the development of solutions and enable the monitoring and adjustment of the manufacturing process (Xu et al., 2011). Through this, manufacturers strive not only to get the future right reliably but also to reshape the decision-maker’s focus and draw attention to areas that may have been disregarded (Weber and Tarba, 2014). Therefore, advanced manufacturing technologies offer manufacturer alternatives and strategic agility that can be used to reconfigure their resources when necessary. Further, advanced manufacturing technologies are crucial in promoting information-sharing functions within and between firms (Pu et al., 2021).

For instance, it has been suggested that structural, organizational changes to implement digital transformation can reorganize the resources of manufacturing firms to navigate changes in market conditions, improving strategic agility (Chesbrough, 2020; Matarazzo et al., 2021). The discussion above is a theoretical argument that warrants empirical validation. Moreover, these theoretical arguments were based on manufacturing firms in advanced economies. So, it is essential to examine the effect of advanced manufacturing technologies on manufacturing firms’ strategic agility in emerging economies. The outcome might differ due to differences in the support and infrastructures offered to them. Hence, we posit that:

H2: Advanced manufacturing technologies have a positive effect on strategic agility.

Strategic agility and sustained competitive advantage

Obtaining a competitive advantage is a complex task that demands competence and expertise (Barney, 1991), especially for firms operating in emerging economies. Strategic agility is a critical factor that ensures survival when competing in a dynamic business environment (Clauss et al., 2021; Mata et al., 2023). Additionally, Teece et al. (1997) argue that resources are limited for firms to achieve superior performance in highly competitive settings to guarantee long-term success. The capacity to develop new competence and resources is a crucial factor for sustained competitive advantage.

Drawing from the extant literature, research has established the link between strategic agility and competitive advantage (e.g., Ahammad et al., 2021; Battour et al., 2021). Battour et al. (2021) and Clauss et al. (2021) demonstrate the critical influence of strategic agility and strategic agility in the exploration-exploitation paradigm to develop competitive advantage. Further, Chen et al. (2020) study provided insights into the impact of the adaptability of information technology infrastructure on competitive advantage through the intervening role of strategic agility.

Research suggests that strategic agility comprises several dynamic abilities such as searching, sensing, seizing, switching, and formulating, and these capabilities are crucial in developing comeptitive advantage (Baškarada and Koronios, 2018). Dabiri and Gholami (2015) suggest that strategic agility may influence competitive advantage via product innovation, quality, reliability, and price. While the link between strategic agility and competitive advantage is well documented in the literature, this relationship has not been specifically established from the limited resources context, such as in Turkish manufacturing industries. To address the void in the existing body of knowledge, we posit that:

H3: Strategic agility has a positive effect on sustained competitive advantage.

Strategic agility as a mediator

As demonstrated by prior research and from a conceptual standpoint (Kotha and Swamidass, 2000; Pu et al., 2021; Wong and Ngai, 2023), advanced manufacturing technologies lead to the achievement of sustained competitive advantage. However, through what mechanism and how advanced manufacturing technologies influence sustained competitive advantage remains ambiguous and underexplored. Therefore, this research focuses on strategic agility as a potential intervening construct between advanced manufacturing technologies and sustained competitive advantage. Hence, this research examines the crucial role (i.e., indirect) of strategic agility in transmitting advanced manufacturing technologies into sustained competitive advantage is examined.

Innovation capabilities can improve strategic agility by accelerating the creation of new products in response to new market opportunities (Chesbrough, 2020; Zahoor et al., 2022). Research indicates that advanced manufacturing technologies transform organizational capabilities by challenging traditional routines, adjustments, and adaptation (Holmström et al., 2019; Kropsu‐Vehkapera et al., 2009). Such transformational capabilities may translate into strategic agility by converting unpredictable changes in market needs into profitable ones to survive and succeed (Kale et al., 2019). This aligns with the dynamic capabilities view. This suggests that strategic agility may be a potential explanatory between advanced manufacturing technologies and sustained competitive advantage.

Furthermore, on the possible intervening role of strategic agility, it is presumed that advanced manufacturing technologies enable manufacturers to have improved control over processes and to rapidly and flexibly respond to consumer demands and adjust strategic directions such as strategic agility (Doz and Kosonen, 2010; Sharma et al., 2021; Wong and Ngai, 2023), which in turn, impact firms’ sustained competitive advantage (Battour et al., 2021). Firms with strong digital manufacturing cultures tend to implement advanced manufacturing technologies solutions (Wong and Ngai, 2023), and such digital manufacturing solutions enhance strategic agility (AlNuaimi et al. 2022). Therefore, research suggested that advanced manufacturing technologies improve strategic agility (Chesbrough, 2020) and that strategic agility positively impacts sustained competitive advantage (Battour et al., 2021). It is reasonable to infer that advanced manufacturing technologies may indirectly affect sustained competitive advantage through strategic agility. Thus, we posit that:

H4: Strategic agility mediates the relationship between advanced manufacturing technologies and sustained competitive advantage.

Business network as a moderator

While this study anticipates a positive relationship between advanced manufacturing technologies and sustained competitive advantage through the perspective of dynamic capabilities theory, the new institutional theory can offer a complementary explanation to account for the conditions under which this relationship is more or less effective. While advanced manufacturing technologies can trigger an increase in firms’ competitive power by accelerating the production systems, increasing the number of products manufactured, and reducing the number of defective products produced within a manufacturing system (Altuntas et al., 2018), they need the necessary knowledge and resources to implement these actions. Competitive advantage is characterized as the alignment between a firm’s strategic approach and its external environment (Powell, 1992).

Moreover, Zairi (1992) described advanced manufacturing technologies as a social-technical system that demands constant evaluation, adaptation, and regular change adjustment in response to environmental competitive pressure. While the crucial role of networks has been acknowledged in operations management research (Zang et al., 2022); business networks as an organizational condition remains unexplored. Business networks relate to the relationships that firms establish with various business entities, such as suppliers, customers, competitors, and other players in the market (Sheng et al., 2011). Congruent with the new institutional theory, we suggest a business network as a catalyst that can make the relationships in our model (Fig. 1) more or less effective.

Regarding advanced manufacturing technologies, rapid technical changes would challenge firms’ ability to acquire technologies, particularly those operating in emerging economies. From this standpoint, a solo firm owns limited capabilities, expertise, and skills. Given that strategic agility is a concrete expression of dynamic capabilities (Brozovic, 2018), it allows firms to adapt and reconfigure resources in response to dynamic market changes. In the case of firms operating in emerging economies, business networks can serve as a crucial strategic advantage for firms to obtain innovation capabilities (i.e., advanced manufacturing technologies) to gain important information on customer needs, market gaps, and survival, particularly where resource limitations are a liability and institutional framework are weak (Li et al., 2008; Zang et al., 2022). This relationship is markedly beneficial, especially in weak institutional contexts, because it helps overcome challenges (Welter and Smallbone, 2011). Based on the new institutional theory, this study views business networks as a crucial strategic resource that will further advance sustained competitive advantage when complemented with strategic agility.

Furthermore, a business network improves firms’ knowledge base, lowers technological constraints (Li et al., 2020), and helps firms acquire valuable innovation capabilities to bootstrap their operations (Chesbrough, 2020). Information, resources, and key technologies can help firms exploit opportunities that reflect new market changes and preferences (Kale et al., 2019; Zhao et al., 2024), advancing strategic agility. This study proposes that business networks can further strengthen advanced manufacturing technologies and strategic agility relationships.

In addition, for firms embedded in networking activities that connect them with market players such as customers, suppliers, and competitors, strategic agility is more likely to help them sustain their competitiveness. Strategic agility allows firms to take advantage of updates regarding new technologies to fulfill market requirements and needs for the improvement of manufacturing operations and competitiveness (Zhang et al., 2006; Small and Yasin, 1997). Establishing connections with stakeholders can give manufacturers crucial access to resources and information, allowing them to undertake cost-effective activities. Thus, consistent with the new institutional theory, it can be suggested that business network can provide crucial access to innovation capabilities (e.g., advanced manufacturing technologies), which can then be used by manufacturers to enhance strategic agility, as well as improve resource efficiency and competitiveness (i.e., sustained competitive advantage). Therefore, this study proposes the following:

H5: Business networks strengthen the relationship between advanced manufacturing technologies and strategic agility, such that the strength of the relationship will be stronger for manufacturers who heavily utilize their business network as opposed to manufacturers who do so minimally.

H6: Business networks strengthen the relationship between advanced manufacturing technologies and sustained competitive advantage, such that the strength of the relationship will be stronger for manufacturers who heavily utilize their business network as opposed to manufacturers who do so minimally.

H7: The effect of advanced manufacturing technologies on sustained competitive advantage through strategic agility will be stronger for manufacturers who heavily utilize their business networks than for manufacturers who do so minimally.

Methods

Research context

The manufacturing sector accounts for 84% of Turkey’s overall production, making it the most important industrial sector in the country (UNDP, 2023). Türkiye is a prominent and well-established global manufacturer and supplier of various products such as textiles and apparel, machinery, and automotive, and integrates same into the global value chains (Türkiye: A Global Manufacturing Hub, 2023). From this standpoint, collaborations between Turkish firms and international businesses are on the rise, engaging in contractual agreements with local manufacturers while also building their manufacturing facilities. Alongside Vietnam and Mexico, Türkiye is emerging as a promising manufacturing hub for corporations seeking to expand their operations from traditional manufacturing destinations, such as China (Türkiye: A Global Manufacturing Hub, 2023).

International businesses are using Türkiye to implement advanced technologies in manufacturing processes (Türkiye: A Global Manufacturing Hub, 2023). Since manufacturing firms in emerging markets cannot innovate independently (Zang et al., 2022), business networks become more important for firms operating in emerging markets such as Turkey to acquire the necessary resources to develop a sustained competitive advantage. Moreover, Moon et al. (2014) and Ahsan et al. (2021) argued that external environmental factors such as social and business networks should be considered, particularly for firms operating in emerging markets. Consistent with this, the Turkish manufacturing industry offers a rich research context to understand how advanced manufacturing technology translates into sustained competitive advantage under what conditions.

Ethical consideration

Before commencing the study, ethical approval was received from the university’s ethical committee, which declared that the research would abide by all ethical rules while conducting the research. The ethical approval form, dated January 4th, 2023, was issued on behalf of the ethical committee by Prof Dr Hikmet Secim of Akdeniz Karpaz University. Before commencing the study, written consent was given to the participants, and was sent electronically. With written consent, they declared their willingness to participate in the study or withdraw at any given time (see Appendix A). After reading the consent form, the participants agreed to the terms of participation and provided their consent to participate.

Sampling and procedure

This study targeted Turkish manufacturing firms across various industries in the Trade Gazette of Türkiye. Through the purposive sampling method (see, Al Tera et al., 2024), cross-sectional data was collected from manufacturing firms that are implementing advanced manufacturing technology in their operations in Istanbul, Izmir, and Gaziantep industrial cities. The survey participants were senior-level managers of the selected manufacturing firms. An invitation letter was sent electronically to the potential survey participants where the study research objectives were outlined, and agreement on confidentiality was included in the invitation letter.

Targeting manufacturing firms from several industries promotes our sample’s diversity and increases our findings’ generalizability. For firms that accepted our invitation, a facilitator was assigned to help with the survey and ensure a high response rate. To increase our sample size, the facilitators visited firms that did not respond to our invitations, and these firms were encouraged to participate in our survey. For the survey administered electronically, respondents were given assurance that their responses would not be disclosed or shared with external entities or utilized for any purposes beyond the scope of this research. The questionnaire link is included in the email sent to the respondents. For those administered through in-person visits, the same procedure was followed. In total, 822 questionnaires were administered from September 2022 to January 2023. 419 responses were received; however, after removing the survey with missing data, 403 valid responses were retained, resulting in a response rate of 49.03%. The information on the sampled firms is presented in Table 1.

Based on industry, textile and garment account for 22 (5.46%), electronic and communication manufacturing 36(8.93%), pharmaceutical 19 (4.72%), general products 88(21.84%), machinery manufacturing 31 (7.69%), food and beverages 102 (25.31%), building and materials 79 (19.60%) and miscellaneous 26 (6.45%). As per firm size (i.e., number of employees), within 30 accounts for 40 (9.93%), 31–50, 72 (17.87%), 51–70, 84 (20.84%), 71–90, 151 (37.47%) and above 90, 50 (13.89%). Based on firm age, within 20, 59 (14.64%), 21–40, 216 (53.60%), 41–60, 81 (20.10%), 61–80, 39 (9.68%) and above 80, 8 (1.98%).

Measurement items

Advanced manufacturing technologies were measured using 8 items adopted from Boyner and Boyer and Pagell, 2000; Wong and Ngai, 2023. Participants were asked to rate the extent to which advanced manufacturing technologies such as computer-aided manufacturing, robotic applications, real-time process control systems, and so on are used in their firm’s manufacturing activities. Strategic agility was measured with ten items adopted from (Khan et al., 2021).

The business network was measured with 3 items adopted from (Lau and Bruton, 2011; Yiu et al., 2007). The respondents were asked to rate to which extent their firms used business connections and networks in relation to major market actors such as suppliers, customers, and competitors during the past 3 years.

Sustained competitive advantage was measured with 4 items adopted from (Salunke et al., 2013; 2019).

Non-response bias and common method bias

Multiple tests were conducted to examine potential biases in this research. First, we examined the non-response bias by comparing those who responded with those who did not respond for the final sample. Following Greenwood and Nikulin’s (1996) Pearson’s chi-square test for categorical data, it was found that there was no significant difference between respondents and non-respondents based on industry and firm size. Based on the result, non-response bias is not seen as a serious issue in our study. Second, through principal component analysis and varimax, all the measurement items were loaded in an exploratory factor analysis. The test shows that the first of all factors with eigenvalues higher than 1 explained 30.69% of the total variance, indicating that no single factor emerged as a dominant factor as a result of CMB. Third, the marker variable approach of Lindell and Whitney (2001) was employed; the results indicate that the correlation between the theoretically unrelated construct included in the model had a low correlation (0.02) with the main construct of the model. Therefore, CMB does not seem to be a major concern in our study.

Finally, following Iyiola and Rjoub (2020), we examined the variance inflation factor (VIF) values for all dependent constructs and found that the highest VIF of 3.83, which is below the cut-off limit of 5 (Hair et al., 2010) showing that our results are not distorted by multicollinearity. Consistent with the ex-post procedures, issues related to CMB are not a major concern in our study.

Measurement model

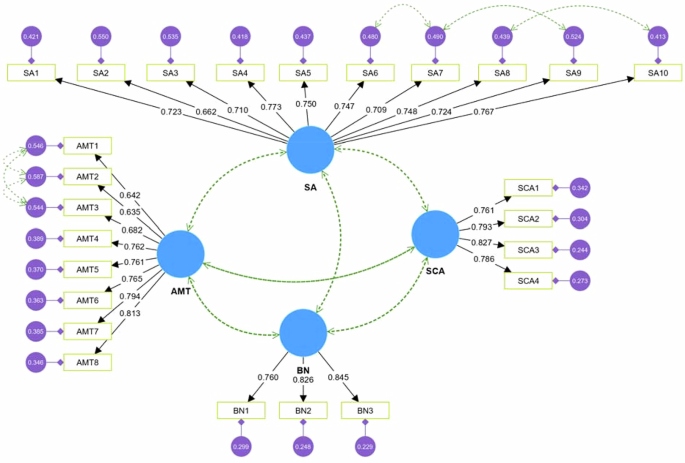

The results of the measurement model are demonstrated in Table 2. We computed the reliability and validity of the data collected. Cronbach’s alpha (α) was used to examine the internal consistency of the measurement item. Table 2 shows that α values for all constructs were higher than 0.7 (0.854 and 0.922), indicating an appropriate consistency between the measurement items and the constructs. The composite reliability (CR) values were also higher than 0.7 (0.852 and 0.920), showing a high level of reliability for the measurement constructs. The data’s validity was demonstrated through its convergent and discriminant validity. We checked for convergent validity through factor loadings and average variance extracted (AVE). Figure 2 and Table show that the factor loadings were higher than 0.6 (0.635 and 0.845) and AVEs higher than 0.5 (0.536 and 0.658). Based on these results, convergent validity is ensured in this study. Further, the test of discriminant validity proposes that the square root of all constructs under observation should be higher than the nearby correlation coefficients (Fornell and Larcker, 1981). In addition, Bagozzi and Yi (1988) argued that if the square root of AVE is higher than 0.7, it is considered that the model demonstrates sufficient discriminant validity. Table 3 shows that both conditions are met, and discriminant validity is ensured in the current research.

Source: authors compilations.

Lastly, the goodness of fit was estimated through confirmatory factor analysis (CFA) with maximum likelihood method, which involved assessing several fit indices; (CMIN/df [<3]) = 2.028; root mean square error of approximation [<0.08] = 0.051; Tucker-Lewis index [>0.9] = 0.953; goodness of fit index [>0.9] = 0.905; normed fit index [>0.9] = 0.921; comparative fit index [>0.9] = 0.958), indicating that the data collected align well with the model (Bagozzi and Yi, 1988).

Hypotheses testing: main effects and mediation

The study tested the main effects and mediating effect using PROCESS macro (Model 4) (Hayes, 2022). As reported in Table 4, advanced manufacturing technology has a positive effect on sustained competitive advantage (β = 0.279 and CI [0.165,0.395], p < 0.001). Advanced manufacturing technologies (β = 0.842 and CI [0.772,0.991], p < 0.001). Strategic agility has a positive effect on sustained competitive advantage (β = 0.482 and CI [0.377,0.587], p < 0.001). Consistent with these results, we found support for hypotheses H1–H3.

Furthermore, we adopted the traditional method by Baron and Kenny (1986) and the bootstrapping mediation approach by Hayes (2022) to conform to the mediating effect of strategic agility. Following Baron and Kenny’s (1986) technique, the direct effect of advanced manufacturing technologies on sustained competitive advantage remained significant after including strategic agility as the mediator. Thus, a partial mediating effect is observed. The statistical significance of the indirect effect was further examined via the bootstrapping method to confirm the mediation effect.

To compute the indirect effect, a bias-corrected bootstrap was executed for 5000 resamples (Hayes, 2022), which was recently adopted by (Al Tera et al., 2024; Iyiola et al., 2023) with a 95% confidence interval was employed. Based on this approach, Table 4 shows that the direct and indirect effects were significant and the unstandardized indirect effect = 0.399 with [0.287, 0.546] of 95% bias-corrected confidence intervals (Bootlower and Bootupper). The Bootlower and Bootupper values did not contain zero. Therefore, strategic agility partially mediates the effect of advanced manufacturing technologies on sustained competitive advantage, and we found support for H4.

Assessment of moderation effects

Using the PROCESS Model 59 (Hayes, 2022), we integrated all the constructs of the study into the model. Also, industry and firm size were added as covariates into the model. Given that the main and indirect relationships were examined in the preceding section. Model 59 proposes that the moderator (i.e., business network) affects all the paths in the model (demonstrated in Fig. 1). Table 5 demonstrates the results of the moderation analyses. However, the results in model 1 demonstrate that the effect of advanced manufacturing technology on strategic agility is significant and positive β = 0.605, t = 13.591, p < 0.001, CI [0.517, 0.692]. However, the business network did not moderate the direct effect β = 0.028, t = 0.956, p > 0.05, CI [−0.871, 0.031]. Thus, we did not find support for H5.

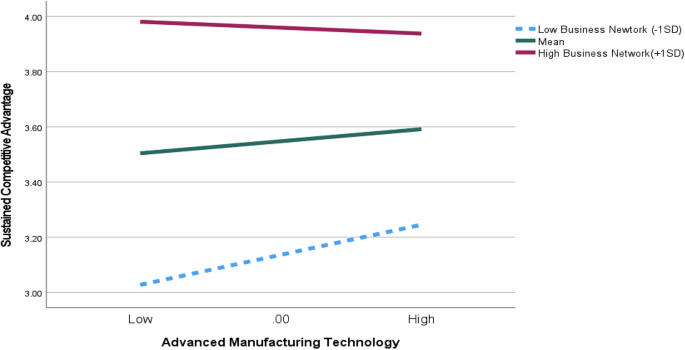

The results show that in model 2, advanced manufacturing technologies positively affect sustained competitive advantage β = 0.216, t = 4.134, p < 0.001, CI [0.100, 286]. The results indicate that the business network significantly and positively moderated this relationship β = 0.120, t = 2.215, p < 0.05, CI [0.011, 0.229]. Following the recommendation of Aiken et al. (1991), a simple slope test was employed to observe how different values of the moderator (business network: −1SD below the mean, Mean, +1SD above the mean) influence the effect of advanced manufacturing technologies on sustained competitive advantage. The graphical output of the simple slope analysis is demonstrated in Fig. 3.

Source: authors compilations.

The results indicate a significant relationship only at high level of business network: low level of business network (−1SD) β = 0.031, t = 0.407, p > 0.05, CI [−0.178, 0.117]; mean level of business network β = 0.062, t = 1.174, p > 0.05, CI [−0.042, 0.166]; high level of business network (+1SD) β = 0.155, t = 2.578, p < 0.01, CI [0.037, 0.272]. Although the results indicate a non-significant effect at low and mean levels of the business network, however, the strength of the effect of advanced manufacturing technologies on sustained competitive advantage increases as the level of the business network increases, offering support for H6.

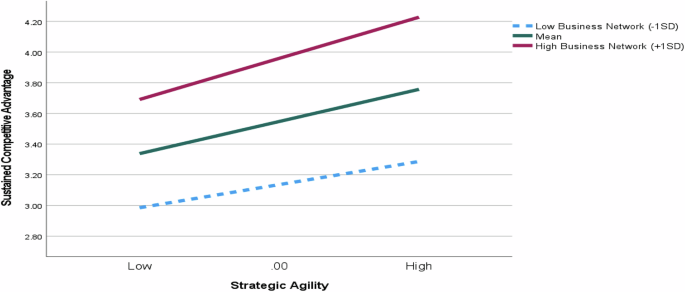

Furthermore, given that the conditional role (i.e., moderating) of business networks in the relationship between strategic agility and sustained competitive advantage was significant, in line with H7, a moderated mediation analysis was examined. The results indicate that the indirect effect of advanced manufacturing technologies on sustained competitive advantage through strategic agility was insignificant at both mean and high levels of business network and insignificant at low levels of business network: low level of business network (−1SD) β = 0.122, SE = 0.061 CI [−0.024, 0.219]; mean level of business network β = 0.164, SE = 0.042, CI [0.085,0.0.249]; high level of business network (+1SD) β = 0.202, SE = 0.058, CI [0.108,0.333]. The indirect effect of advanced manufacturing technologies on sustained competitive advantage via strategic agility is not significant at a low level of business network. However, the strength of the indirect effect substantially increases as the levels of the business network increase (demonstrated in Fig. 4), offering support for H7.

Source: authors compilations.

Discussion

Firms in manufacturing are struggling to stay competitive because of changing digital technology trends (Gillani et al., 2020; Yin et al., 2018), particularly those in emerging markets. However, the lack of knowledge regarding the mechanisms and the conditions enabling the use of advanced manufacturing technologies poses challenges to the practitioners. Drawing from dynamic capabilities theory and new institutional theory, this study examines the impact of advanced manufacturing technologies on sustained competitive advantage from Turkish manufacturing firms’ context.

The findings show that advanced manufacturing technologies positively impact sustained competitive advantage. This particular result is in alignment with (Wong and Ngai, 2023), and also it gives empirical support for the theoretical explanations that numerous advanced business production processes can be integrated through the adoption of advanced manufacturing technologies to improve the level of productivity and competitive power (Baldwin et al., 2003; Altuntas et al., 2018). Most importantly, advanced manufacturing technologies promote efficiency and flexibility, contributing to low-cost strategies toward implementing concrete competitive strategies (Pu et al., 2021; Xian et al., 2023). Advanced manufacturing technologies positively impact strategic agility. This empirical result offers support for theoretical arguments that advanced manufacturing enabled by digital transformation helps firms to reconfigure their resources, navigate changes in market conditions, and makes firms more agile (Chesbrough, 2020; Matarazzo et al., 2021; Pu et al., 2021).

A possible explanation for this result is that, through digitally enabled manufacturing, manufacturers can reconfigure their production processes and adapt to market changes to achieve strategic agility. Strategic agility has a positive impact on sustained competitive advantage. This is consistent with previous research findings (Ahammad et al., 2021; Battour et al., 2021) and offers additional support for the dynamic capabilities view (Teece et al., 1997). The consistencies in these results from an emerging economy perspective may imply that competitive advantage arises when manufacturing firms develop, integrate, and reconfigure internally and externally to address competitive needs.

The relationship between advanced manufacturing technologies and sustained competitive advantage partially mediated strategic agility. An explanation for this indirect effect is that strategic agility analyzes firm capabilities, and through the motivations from strategic agility, manufacturers equipped with advanced manufacturing technologies can take more intuitive actions to achieve sustained competitive advantage. Strategic agility is a mechanism of digital manufacturing (e.g., advanced manufacturing technologies) and novel manufacturing processes that promote sustained competitive advantage. Further, based on the dynamic capabilities theory, strategic agility improves firms’ ability to proactively renew and adapt their business model to environmental changes (Battistella et al., 2017; Clauss et al., 2021). Drawing from these, it seems that integrating advanced manufacturing technologies into manufacturing processes can promote strategic agility, enhancing efficiency and productivity.

Additionally, the results of this study show that advanced technologies directly affect sustained competitive advantage and indirectly through strategic agility; these effects are stronger when manufacturers extensively use their business network. One possible reason for these results is that the extensive use of business networks is a driving force that provides resources and triggers firms to continually seek the adaptation of digital manufacturing technologies in manufacturing processes to increase corporate success. Even though advanced manufacturing technologies offer firms flexibility and cut-down prices (Wong and Ngai, 2023), as indicated by this study’s findings, it is not enough to increase competitive advantage.

From the perspective of new institutional theory, being embedded in networks allows firms to acquire complementary resources to advance corporate success (Li et al., 2020). Nonetheless, our results suggest that the impact of advanced manufacturing technologies on sustained competitive advantage through strategic agility is boosted when manufacturers extensively leverage their business network. Congruent with this, adaptation to new technologies and skills that offer access to diverse information and knowledge can be obtained to advance sustained competitive advantage.

Implications for theory

This study makes several theoretical contributions that help advance research in operations management in digital manufacturing from an emerging economy perspective. Based on the sample collected from Turkish manufacturing firms and the findings of this study that revealed advanced manufacturing technologies positively impact achieving sustained competition, this research offers empirical evidence that advances the less-researched literature stream that has underlined the importance of advanced manufacturing technologies for competitiveness as asserted by some authors (Wong and Ngai, 2023). Thus, this research advances the theorization of both advanced manufacturing technologies and sustained competitive advantage, particularly in emerging economies where digital capabilities have been discovered to help mitigate uncertainties and boost performance (Altuntas et al., 2018; Al Tera et al. 2024).

Research has demonstrated that advanced manufacturing technologies influence sustained competitive advantage. Despite this, limited knowledge exists on the mechanisms through which implementing advanced manufacturing technologies in manufacturing processes results in sustained competitive advantage. Specifically, the exact relationship between advanced manufacturing technologies and strategic agility lacks empirical validation. The extant literature has not sufficiently provided how advanced manufacturing technologies influence strategic agility. This study strengthens the theorization of these constructs by being one of the first studies to demonstrate how advanced manufacturing technologies influence strategic agility.

Given the claimed advantages of advanced manufacturing technologies, such as synchronization of processes and real-time access (Altuntas et al., 2018; Fosso Wamba et al., 2020), these advantages have been under-leveraged or insufficient to stimulate key production functions in manufacturing environments (Altuntas et al., 2018), with the reason being the lack of understanding of the mechanisms and the knowledge gap in advanced manufacturing technologies in advancing competitive advantage in different contexts. By integrating the critical role of strategic agility in this context and demonstrating that strategic agility is a mechanism through which the impact of advanced manufacturing technologies achieving sustained competitive advantage can be better explained. Thus, this study advances the literature on the use of dynamic capabilities for sustained competitive advantage benefits.

Moreover, in the current business climate, insights into digital manufacturing and sustained competitive advantage are critical for dynamic capabilities, especially for manufacturing firms in emerging economies. To develop sustained competitive advantage, firms must use strategic agility to manage, anticipate changes, and reconfigure production processes to fuel dynamic capabilities toward achieving sustained competitive advantage. Thus, we demonstrate how advanced manufacturing technologies affect sustained competitive advantage and close the research gap identified by (Wong and Ngai, 2023).

Furthermore, this study advances the dynamic capabilities theory and the new institutional theory by integrating business networks into our integrated theoretical framework and uncovers the conditions under which the effect of advanced manufacturing technologies on sustained competitive advantage works. Teece (2009) highlights that dynamic capabilities can enable firms to achieve sustained competitive advantage, yet limited research has explored the sources of dynamic capabilities of firms in emerging economies. Moreover, contexts matter, and consistent with the new institutional theory, the activities of firms are deeply rooted in a specific institutional environment.

By demonstrating that advanced manufacturing technologies-sustained competitive advantage relationship is stronger for firms who extensively utilize their business networks, this study provides answers to “common questions” regarding when (i.e., under what condition) dynamic capabilities (e.g., advanced manufacturing technologies) can be used to advance sustained competitive advantage. Finally, the indirect positive impact of advanced manufacturing technologies on sustained competitive advantage through strategic agility is stronger for firms who extensively utilize their business network. Therefore, it is helpful for manufacturers seeking to boost their competitive advantage to do it through strategic agility.

Implications for practitioners

The findings of this research yield various valuable managerial insights and practical implications, especially for manufacturing firms in emerging economies, on the role of advanced manufacturing technologies and strategic agility in achieving sustained competitive advantage and the condition under which business networks are beneficial for advancing sustained competitive advantage. Modern advances in automated manufacturing technologies have immensely decreased processing and transportation times and costs (Ungan et al., 2015). This study demonstrates the importance of implementing advanced manufacturing technologies in achieving the desired firm outcome. Advanced manufacturing technologies not only promote efficiency but also help in developing sustained competitive advantage. Despite the challenges encountered by firms in emerging economies such as Turkey in implementing advanced manufacturing technologies into production processes due to limited resources, performance improvements can make such investments worthwhile.

In the current business climate, managers face the challenges of balancing multiple objectives such as cost-effectiveness, quality, customization, and delivery, all while under pressure to accomplish the desired results (Gillani et al. 2020). This research demonstrates various digital technologies that can generate beneficial outcomes in this management pursuit. Integrating highly precise technologies such as robotics in artificial intelligence stimulate the design of quality products. Further, the importance of advanced manufacturing technologies in achieving sustained competitive advantage among Turkish manufacturing firms may not be fully realized if it is not combined with strategic agility. Strategic agility can enable additional information on market needs to help firms reconfigure, renew, and transform strategically. Thus, firms should consider advanced manufacturing technology as a source of competitive power.

Furthermore, the direct and indirect impacts of advanced manufacturing technologies were stronger for firms using their business network extensively. Therefore, managers should pay close attention to the interaction effect between advanced manufacturing technologies and business networks on sustained competitive advantage in their managerial pursuits. Manufacturing firms that can nurture and leverage business networks are likely to experience improved performance and advance sustained competitive advantage. Such manufacturing firms can obtain privilege connections and have access to resources that can help adapt and respond to technological and environmental changes. Hence, managers should focus on managing their business networks, which would make their firms more flexible and agile, and make them better equipped to respond in the context of environmental and technological changes.

Conclusion

The present research fills relevant research voids in the operation management literature through empirical research from the manufacturing industries. Grounded on the dynamic capability theory and the new institutional theory, this study significantly extends our knowledge of the relationship between advanced manufacturing technologies and sustained competitive advantage by exploring the mediating role of strategic agility and the moderating role of business networks. The current research successfully demonstrated the impact of advanced manufacturing technologies on sustained competitive performance through the bridging role of strategic agility from an emerging economy context. The research further highlights that business network effectively improves strategic agility and sustained competitive advantage.

Limitations and future research directions

Despite the crucial contributions of this research, it also has its own limitations. First, the findings of this study were based on a cross-sectional design from a single source (i.e., senior-level managers), which may limit its generalizability. Future research may adopt a longitudinal research design because technology implementation occurs over an extended period. Second, it is anticipated that the proposed and examined relationships will apply to other emerging economies with characteristics similar to Turkey. However, additional empirical validation is needed (Wong and Ngai, 2023).

Hence, additional research is required in emerging economies where implementing digital technologies is expected to have a larger effect on manufacturers’ performance-related outcomes than in advanced economies because manufacturers in emerging economies generally have lower technological proficiency. Third, other mechanisms were not considered in this study. For example, the performance implications of the adoption of advanced manufacturing technologies may be partially influenced by financial measures; this can be a good avenue for future studies in emerging economies.

Finally, the relationship between digital manufacturing, such as advanced manufacturing technologies, and sustained competitive advantage in emerging economies warrants additional scholarly investigation to determine if other external or conditional factors may be hindering the technological competence of firms in emerging economies.

Responses