Exploring thitsi in Qing Dynasty lacquerware: Insights from a preliminary study

Introduction

Chinese lacquerware represents a profound continuum of technological and artistic development, transitioning from early monochromatic forms to later polychromatic complexities, and evolving from straightforward lacquering to intricate engraving and inlay techniques. This progression not only mirrors the advancement of lacquering techniques but also encapsulates the depth and sophistication inherent in Chinese lacquer culture. In an era marked by burgeoning international exchanges, the materials and products associated with lacquerware have engaged in an increasingly dynamic global dialog. This interaction has fostered a confluence of diverse lacquering techniques and materials, giving rise to a rich tapestry of sophisticated lacquerware traditions that resonate across cultures and epochs.

Raw lacquer serves as the foundational material in diverse lacquerware production techniques, offering vital insights into the origins and typologies of lacquer artifacts. Asian lacquerware predominantly utilizes three principal types of lacquer: urushi, derived from Toxicodendron vernicifluum (Stokes) F. A. Barkley; laccol, sourced from Toxicodendron succedaneum (L) Kuntze; and thitsi, obtained from Gluta usitata (Wall.) Ding Hou1,2. The conventional understanding has long held that Chinese lacquerware predominantly utilized urushi, with its earliest known use dating back to 8000 BP3. This perspective stems from the historical abundance of Toxicodendron vernicifluum in China and the relatively limited scientific investigation into the diversity of lacquer sources4,5. While modern advances in analytical technologies have enabled more precise differentiation among these lacquer types, urushi continues to predominate in identification efforts, thus perpetuating this conventional perspective6,7,8,9,10,11.

This prevailing perspective warrants reevaluation. The robust trade and cultural interactions that historically linked ancient China with Southeast Asia facilitated the exchange of various types of raw lacquer, thus enriching the lacquerware landscape. Contemporary research underscores that during the late Ming Dynasty (1368-1644 CE), Southeast Asian regions contributed additional lacquer types to China, suggesting a far more intricate panorama of lacquerware material sources than previously acknowledged4,12. Moreover, the unique performance characteristics and variable costs associated with different lacquers imply that ancient artisans strategically selected raw lacquers based on specific technical requirements, performance expectations, and market dynamics.

This evolving perspective is supported by recent studies presenting compelling evidence of laccol identified in multiple samples of lacquerware exported from China, dated to the 16th to 19th centuries4,5,12 as well as the detection of thitsi in artifacts from Japan dating back to the 17th century13. These findings not only demonstrate the material diversity within the realm of lacquerware but also underscore the intricate and sophisticated techniques employed in its production, revealing a complexity previously underestimated in historical accounts.

Since 2019, studies have identified the presence of laccol in lacquerware from the Southern Song Dynasty (1127-1279 CE), offering significant insights into the material diversity of Chinese lacquer traditions14,15. More recently, analyses in 2024 revealed the use of laccol as a binding medium in Neolithic painted pottery, scientifically dated to 6000-5300 BP16, marking the earliest known application of this material in China. These findings challenge longstanding assumptions regarding the uniformity of lacquer sources, necessitating a nuanced reexamination of the resource procurement and material practices associated with traditional lacquerware production.

The probability that thitsi, predominantly sourced from Southeast Asian nations such as Myanmar, Cambodia, Thailand, and Laos, was utilized in Chinese lacquerware fabrication further challenges established narratives. Therefore, the identification of thitsi in Chinese cultural artifacts could provide valuable academic and practical insights, particularly in light of the limited historical documentation and the lack of concrete scientific evidence available to date.

The utilization of different lacquer species in lacquerware production is an area of research that demands greater scholarly attention. Current studies largely indicate the use of a single type of lacquer in most lacquerware artifacts3,17,18,19. However, in some instances, the mixed-use of various lacquers has been observed, either through the application of different lacquers in distinct layers of multi-layered lacquerware or the blending of multiple lacquers within the same layer. Documented examples include combinations such as urushi and laccol20, urushi and thitsi21, laccol and thitsi22,23, and even mixtures of all three24. A common practice has been to apply high-performing but expensive urushi on the outer surface while utilizing more cost-effective laccol or thitsi in the underlying layers for economic efficiency. Despite these findings, the extent and diversity of mixed lacquer use remain underexplored, signaling the need for further research and verification.

The production of lacquerware typically involves the use of multiple materials, and analysis of these materials is essential for enhancing both understanding and preservation. To date, researchers have employed a variety of analytical techniques, including optical microscopy (OM), scanning electron microscopy – energy dispersive spectroscopy (SEM-EDS), Raman spectroscopy (RS), Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), and pyrolysis – gas chromatography / mass spectrometry (Py-GC/MS). These methods have been instrumental in identifying lacquer types, pigments, lacquer ash, fabrics, and other components, thus revealing the remarkable diversity of materials involved in lacquerware production14,25,26,27,28,29,30.

In an era of rapidly advancing scientific and technological analysis methods, the Getty Conservation Institute (GCI) and the J. Paul Getty Museum have developed a suite of innovative techniques, including sampling, staining, and data interpretation4. These methods are capable of identifying organic compounds in lacquerware from trace samples31, offering rapid and precise data retrieval and interpretation4,32,33. This approach enhances our understanding of the material composition of lacquerware and provides a basis for the conservation of these complex artifacts.

With the establishment of new trade routes in the 16th century, lacquer products, including Coromandel lacquerware, began to be transported in significant quantities to Europe via maritime routes. This facilitated not only the international exchange of lacquerware but also the potential circulation of raw materials across regions. Building on this context, we conducted sampling and analysis of Ming and Qing Dynasty (1644-1911 CE) lacquers from collections in southeastern coastal provinces of China, areas historically known for their prominent port cities. Our research has yielded notable findings in a Coromandel lacquer screen housed at the Jinhua Museum in Zhejiang Province. These results suggest possible evidence of cross-regional movement of lacquer raw materials and their application in Chinese lacquerware production, offering further insights into the broader history of material exchange.

Materials and methods

Sample

This study centers on a Coromandel lacquer screen from the collection of the Jinhua Museum in Zhejiang Province. The lacquer screen, rediscovered in 2015 during the museum’s inventory review, was originally acquired through folk collection in the 20th century. It consists of six panels, each measuring approximately 274 cm in height and 53 cm in width (Figs. 1 and 2). The front of the screen features intricate engravings of The Celebration of General Guo Ziyi’s Birthday (郭子仪祝寿图), a motif symbolizing prosperity and wealth, commonly seen in Chinese Coromandel lacquer screens. Surrounding the main image are traditional Chinese decorative patterns, contributing to the screen’s sophisticated and elegant design. The reverse side of the screen is inscribed with poetry from the Ming and Qing dynasties34.

Front view of the Coromandel lacquer screen from the Jinhua Museum collection.

Reverse side of the Coromandel lacquer screen from the Jinhua Museum collection.

The sample analyzed in this study was a naturally detached flake from the back of the fourth panel (Fig. 3). The front of the sample exhibited a black lacquer surface over a yellow ash layer, with traces of white and black particles, suspected to be dirt. The sample was divided into two portions for analysis: one part was embedded in resin for cross-sectional microscopic observation, while the other was carefully subjected to micro-excavation for layer-by-layer sampling.

Close-up of the sample under 30× magnification.

Analytical methods

OM analysis of cross-sections

A fragment of the sample was carefully embedded in a transparent, single-component photo-curing resin to facilitate cross-sectional analysis. The embedded sample was subsequently polished with Micro-Mesh® abrasive papers, employing a sequential refinement process up to a fineness of 12,000 grit, thereby ensuring an impeccably smooth and even surface for detailed examination. The polished cross-sections were then examined under a Leica DM4000 M LED optical microscope, alternating among incident white light, ultraviolet (UV) light, and blue light illumination. The UV and blue light were used to enhance the visualization of specific material characteristics, offering a more detailed insight into the stratigraphy of the lacquer layers.

Stratified micro-excavation and layer-specific sampling

The cross-sectional sample was subjected to comprehensive examination using both visible and UV microscopy to elucidate the structural composition and assess the integrity of individual lacquer layers with clarity. Sampling for Py-GC/MS analysis was performed with exceptional precision, using a micro-chisel to extract material from a defined area of approximately 2 × 2 mm. This meticulous “excavation” involved removing individual layers one at a time under a stereomicroscope, with both visible light and a high-intensity UV spotlight ensuring the integrity of each stratum.

Throughout the sampling process, cross-sectional photomicrographs were regularly consulted to guide the accurate identification and isolation of each layer. Scrapings from the target layer were carefully gathered onto single-depression microscope slides, and sampling ceased immediately upon exposure to the next underlying layer to prevent cross-contamination. Layers exceeding 20 µm in thickness were typically sampled with minimal contamination from adjacent layers, ensuring the integrity and purity of each stratum for subsequent analysis.

THM-Py-GC/MS analysis of lacquer layers

THM-Py-GC/MS analysis was performed on both collected layers to elucidate their chemical composition. The analyses were conducted using a Frontier Lab PY-3030D double-shot pyrolyzer system, with the pyrolysis interface set at 320 °C. This system was coupled with an Agilent Technologies 5977C inert mass selective detector (MSD) and 8890 A gas chromatograph/mass spectrometer (GC/MS), utilizing a J&W DB-5MS-UI capillary column (30 m × 0.25 mm × 0.25 µm) for separation.

Helium was employed as the carrier gas, maintained at a flow rate of 1 mL/min. The split injector was set to 320 °C with a split ratio of 50:1. The GC oven was programmed to hold at 40 °C for 2 minutes, then ramp up to 320 °C at 6 °C per minute, followed by a 9-minute isothermal hold to ensure complete separation of the analytes. The mass spectrometer parameters included a transfer line temperature of 320 °C, a source temperature of 230 °C, and a quadrupole temperature of 150 °C. The mass spectrometer was set to scan a mass range of 10-600 amu at a rate of 2.59 scans per second.

Sample preparation involved placing lacquer material in a 50 µL stainless steel Eco-cup fitted with an Eco-stick. A 25% methanolic solution of tetramethyl ammonium hydroxide (TMAH) was added (3 µL) to facilitate derivatization. After a 3-minute reaction period, the sample was purged with helium for 3 minutes and then subjected to single-shot pyrolysis at 550 °C for 6 seconds.

Marker compounds representative of the lacquer components were identified, and peak area percentages were calculated for comprehensive analysis. A detailed report was generated using the RAdICAL ESCAPE expert system, developed by the GCI and the J. Paul Getty Museum. This analytical methodology ensured an accurate and insightful examination of the chemical composition of the lacquer samples, offering a deep understanding of their material properties.

Results

Cross section

The cross-sectional structure of the artifact sample, observed under visible, UV, and blue light, is shown in Fig. 4. After resin embedding, the total thickness of the sample was measured at approximately 1312 µm, with two distinct layers, A and B, identified from top to bottom. The residual material observed in the lower portion of layer B can be attributed to the partial retention of the embedding resin. This outcome reflects a deliberate methodological compromise: given the use of minimal sample quantities, complete removal of the embedding resin carried the risk of over-polishing, potentially resulting in the loss of critical information or even the destruction of the sample.

a Visible light, b UV light, c blue light.

Layer A, the surface black lacquer film, measures around 65 µm in thickness and appears uniformly black under all three lighting conditions. Layer B, with a thickness of approximately 1247 µm, exhibits a red hue with scattered white spots under visible light. Under UV and blue light, the presence of black spots becomes more pronounced, suggesting that this layer represents the underlying lacquer ash.

Once the stratigraphy of the sample was established, micro-sampling was conducted on both layers A and B for further material characterization through THM-Py-GC/MS analysis.

Lacquer film

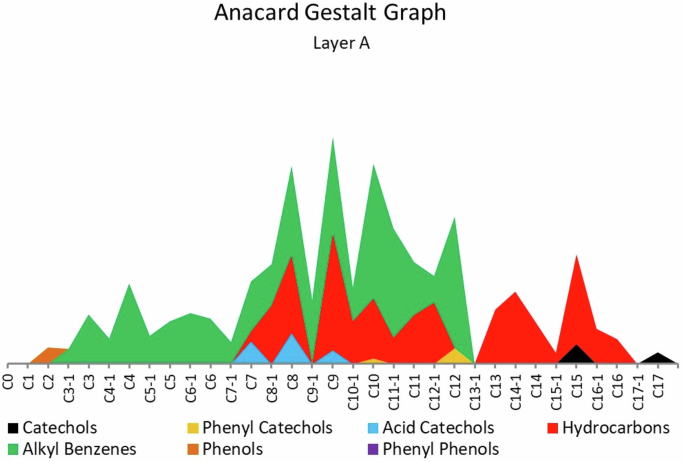

The total ion chromatogram (TIC) of the black lacquer film in Layer A is presented in Fig. 5, with the Anacard gestalt graph in Fig. 6. The surface lacquer film revealed the presence of alkylbenzenes, hydrocarbons, acid catechols, alkyl catechols, and phenyl catechols – compounds typically produced during the pyrolysis of lacquer33. As illustrated in Fig. 6, alkylbenzenes, ranging from propenylbenzene to dodecylbenzene, constitute the primary components, a distinctive feature of thitsi lacquer35. Additionally, key markers of thitsi, such as decylphenol catechol and dodecylphenol catechol, were also identified in the sample, providing further evidence for the use of thitsi in Layer A33. Acid catechols, as oxidation products of catechols, are important indicators in the analysis, and the detection of mazzeic acid – commonly associated with the oxidation of thitsi – further supports the identification of thitsi in the sample33.

TIC profile of Layer A.

Anacard gestalt graph of Layer A.

Thitsi, derived from Gluta usitata, is primarily found in Southeast Asian countries36. Among the three main types of lacquer commonly found in lacquerware artifacts, thitsi is relatively rare and is predominantly associated with lacquerware from Southeast Asia37,38,39,40. Thitsi has also been detected in East Asian lacquerware, particularly in Japan13,21,41,42. Notably, studies by Chang24 and Petisca43 have identified the combined use of thitsi and laccol in lacquerware held within English and American museum collections, providing valuable insights and significant reference points for examining the application of thitsi in Chinese lacquer traditions.

The detection of thitsi in this Coromandel lacquer screen appears to be the first documented instance of thitsi being identified in lacquerware within Chinese collections. This finding may provide new avenues for further investigation into the circulation and application of thitsi in the broader context of Chinese lacquerware production.

A significant amount of methyl monocarboxylate and methyl dicarboxylate was detected in the black surface lacquer film (Fig. 7), suggesting that vegetable oil may have been incorporated into the lacquer solution. Previous studies have shown that different drying oils exhibit specific P/S (palmitic/stearic) and A/P (azelaic/palmitic) ratios4, which can be used to identify the type of vegetable oil present33.

Bar graph of fatty acids and oils in Layer A.

In this sample, the P/S ratio was determined to be 1.3, which closely corresponds to the established values for tung oil and linseed oil7,33. In contrast, the A/P ratio, measured at 0.3, was notably lower than the typical values reported for these drying oils10. This deviation may be attributed to the behavior of azelaic acid, a prevalent oxidation product of drying oils, which likely undergoes preferential crosslinking reactions rather than complete oxidation when drying oil is combined with lacquer44. Such interactions would inhibit the full oxidation of tung oil or linseed oil, resulting in the observed lower A/P ratio38,39. Historically, tung oil was widely utilized as a drying oil in ancient China8,45, and it remains the most frequently identified oil in lacquerware today7,10,30,46,47. Based on these findings, it is reasonable to conclude that tung oil was likely the drying oil employed in the production of this lacquer screen.

Alkyl phenyl alkenoates (APAs), a well-established marker of heated tung oil, were notably absent in our sample. This absence can likely be attributed to the processing method employed in the preparation of the tung oil. Existing literature indicates that APAs typically form when drying oils are subjected to elevated temperatures during processing4,24,48. Consequently, the absence of APAs in our sample suggests that the oil was not exposed to high-temperature treatment, and raw tung oil may have been utilized instead. This observation is consistent with findings from previous studies on painting samples from the Drum Tower in Xi’an, China49.

Furthermore, as illustrated by the TIC of layer A within the 5-12.5 minute retention time range (Fig. 8), the presence of alpha-cedrene (C1), beta-cedrene (C2), and cedrol (C3) were confirmed. These compounds are well-established signature markers of cedar oil47, providing compelling evidence of its presence in the analyzed sample. The use of cedar oil in lacquerware production has a well-documented history24, with its application traceable to artifacts from the Han Dynasty (202 BCE-220 CE)4 and extending to later export lacquerware12,31,47.

TIC profile of Layer A within the 5-12.5 minute retention time range.

The detection of camphor (Ca in Fig. 8) also suggests the use of camphor resin. Although historical Chinese literature on lacquerware does not explicitly mention the use of camphor resin4, it is often employed as a lacquer thinner or fluidizer13. Previous studies have confirmed the presence of camphor in both Japanese50,51 and Chinese lacquerware52. It is noteworthy that, although camphor is occasionally employed by museums as an insect deterrent, such use was not applicable in this instance. Moreover, when camphor is utilized in museum settings, it is typically placed at a safe distance from artifacts, ensuring that no residue comes into contact with the objects. Consequently, we assert that the presence of camphor in this case is more plausibly intrinsic to the sample itself rather than an external contamination.

Lacquer ash

The TIC of Layer B is shown in Fig. 9, with the corresponding gestalt graph presented in Fig. 10. Analysis of the lacquer ash layer revealed the presence of alkylbenzenes, hydrocarbons, and catechols. Notably, pentadecyl catechol and pentadecenyl catechol were detected, indicating the use of urushi8,9. Urushi is derived from Toxicodendron vernicifluum, which is predominantly found in China, Japan, and South Korea1, and is the most widely used type of raw lacquer in East Asia.

TIC profile of Layer B.

Anacard gestalt graph of Layer B.

Acid catechols, commonly used as significant markers for identifying different types of lacquer33, were notably absent in this sample. This could be attributed to the oxidation state of urushi in the lacquer ash layer. Acid catechols are oxidation products of substituted catechols6,53, typically generated under exposure to light. In this case, the black lacquer film covering the lacquer ash layer likely prevented light penetration, potentially inhibiting the production of urushi oxidation products.

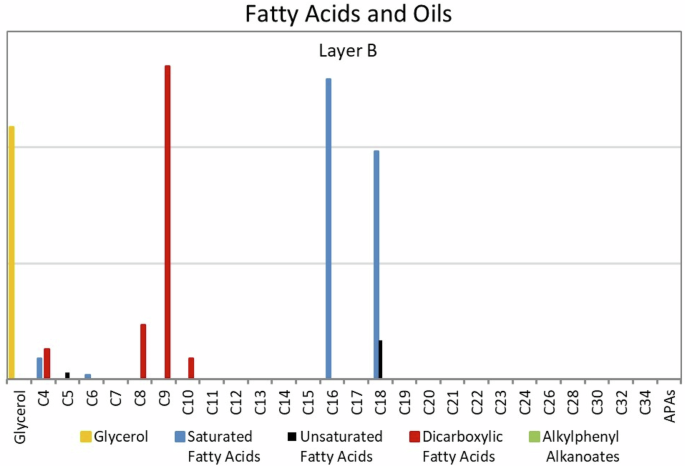

Furthermore, saturated and unsaturated (Fig. 11) methyl monocarboxylates, methyl dicarboxylates, and methyl glycerides were detected, indicating the presence of drying oil6. The P/S value (1.3) and A/P value (1.0) of the lacquer ash are consistent with those of tung oil10,33.

Bar graph of fatty acids and oils in Layer B.

The THM-Py-GC/MS analysis identifies several diagnostic protein marker compounds, including Blood – unverified 5, Blood – unverified 6, Blood – unverified 7, and Blood – unverified 9 (B1-B4 in Fig. 12)33. Additionally, a high degree of correlation (0.97) has been observed between Layer B and the blood reference sample, where a correlation value of 1.0 represents a perfect match and 0.0 indicates no correlation20. This strong correlation may suggest the potential use of blood-based materials in the lacquer ash layer.

TIC profile of Layer B within the 5-15 minute retention time range.

The ancient Chinese text Ge Gu Yao Lun (格古要论) records the frequent use of porcine blood as an adhesive in lacquer ash layers20. Wang’s Xiu Shi Lu Jie Shuo (髹饰录解说) mentions that the ash layer in Coromandel lacquerware must be kept from becoming too hard to facilitate engraving, and is often composed of brick powder, porcine blood, and small amounts of raw lacquer54. Porcine blood, being a low-cost material, provides excellent adhesive and waterproofing properties, and has been used in Chinese lacquer production for over 2000 years55. Its use in Coromandel lacquerware ash layers not only reduces costs but also creates an ideal consistency for engraving, enhancing the functionality and craftsmanship of these artifacts.

While THM-Py-GC/MS provided valuable insights into the potential presence of blood-based materials in the lacquer artifact, the limitations must be considered. Although the correlation coefficient analysis offers an indication of material composition, it lacks the specificity necessary for definitive identification. Despite the relatively high degree of match (0.97) observed between the lacquer sample and the blood reference sample, an outcome notably higher than those reported in the literature (e.g., 0.8, which has been considered sufficient for effective identification)20, this correlation alone is not sufficient to conclusively confirm the presence of blood.

In contrast, if sufficient sample material were available for proteomics analysis, it would enable a more accurate identification of the blood component and could potentially offer definitive insights into its biological species origin. Therefore, future research employing proteomics, spanning both fundamental research on protein additives56,57,58,59,60 and their application in cultural heritage samples61,62,63,64,65 would yield more conclusive evidence. Such studies would address the limitations of current analytical methods and make a significant contribution to advancing the field of lacquerware conservation.

Discussion

This scientific analysis of a Coromandel lacquer screen sample from the Jinhua Museum represents the first identification of thitsi in Chinese lacquerware, providing an intriguing case of mixed lacquer usage. While it is important to note that only a single sample was analyzed, which may not fully encapsulate the variety of materials and techniques employed across the entire Coromandel lacquer screen, the findings nonetheless contribute valuable insights into the diversity and complexity of lacquer materials in ancient China. These results offer a novel perspective that may stimulate further research into the intricate composition and regional variations of lacquerware production during this period.

Given that Gluta usitata, the source of thitsi, is primarily found in Southeast Asia, and there is no evidence of its distribution in other regions, it is plausible that thitsi was introduced to China through established trade routes. Historical records indicate that Chinese merchants collaborated with the Dutch to resell thitsi from Southeast Asia, as well as urushi from China, to Japan13. In this context, it is reasonable to infer that Chinese merchants may have also imported thitsi for domestic use66.

The rationale behind the craftsman’s decision to apply thitsi as the surface lacquer film and urushi as the lacquer ash layer in this particular lacquer screen remains unclear and warrants further investigation. One possible explanation could be rooted in considerations of cost and performance. Economically, thitsi is less expensive than urushi and laccol13. Therefore, incorporating thitsi into the production process could have been an effective cost-control strategy, particularly when manufacturing large-scale furniture like lacquer screens.

The specific characteristics of thitsi may also have influenced its selection for this particular lacquer application. Traditionally, urushi has been preferred for surface coatings due to its well-known ability to enhance color vibrancy and provide a smooth finish. However, the use of thitsi for the surface black lacquer film and urushi applied in the lacquer ash layer, may reflect a conscious decision to leverage the properties of thitsi, particularly its potential to produce a deeper black hue13. Previous research has suggested that thitsi can yield a more intense black color24, which could have been advantageous in meeting the aesthetic goals of this Coromandel lacquer screen. This choice underscores the artisan’s understanding of the distinct attributes of different lacquer types and their ability to select materials that best suit the desired artistic effect.

Conclusions

This study offers a detailed analysis of the organic materials in a Qing Dynasty Coromandel lacquer screen sample from the Jinhua Museum in Zhejiang Province, utilizing microscopic cross-sectional observation, layer-by-layer sampling, and THM-Py-GC/MS techniques. While the analysis is based on a single sample, the findings provide valuable scientific insights that contribute to a deeper understanding of the composition and materiality of this lacquer screen. The results may serve as a foundation for future research, encouraging further exploration into the diverse techniques and materials used in Qing Dynasty lacquerware.

The results revealed two primary layers: a lacquer film layer and a lacquer ash layer. In the lacquer film layer, thitsi, tung oil, cedar oil, and camphor were detected. Notably, this represents the first confirmed identification of thitsi in Chinese lacquerware artifacts, suggesting that thitsi may have been introduced to coastal regions of China through trade and later incorporated into lacquer production. The lacquer ash layer contained urushi, tung oil, and a potential blood-based substance, which we cautiously hypothesize may have originated from pigs.

The study also highlights the selective use of different lacquers in the distinct layers of the Coromandel screen, potentially reflecting considerations such as cost control. Unlike the conventional practice of applying urushi to the surface layers, this artifact features thitsi in the lacquer film and urushi in the lacquer ash layer. This choice may have been influenced by the deeper black hue of thitsi, which could have better met the artistic requirements for the black lacquer on the screen. This approach may indicate the craftsman’s careful consideration of the properties of various lacquer types and their adaptive use in Qing Dynasty lacquerware.

The findings suggest a more complex material selection process than previously recognized and may open new avenues for further exploration of lacquer diversity in Chinese artifacts. Ongoing scientific analysis and historical research will be crucial for deepening our understanding of the range of lacquers used in Chinese lacquerware. This could provide valuable insights into the technological sophistication and historical context of these objects, while also offering guidance for their conservation and restoration.

Responses