New advances in biological preservation technology for aquatic products

Introduction

Aquatic products are known for their delicious taste and rich nutritional value. They contain a significant amount of protein, various vitamins, minerals, and essential organic compounds that humans cannot synthesize on their own, such as docosahexaenoic acid (DHA) and eicosatetraenoic acid (EPA) found in unsaturated fatty acids1. However, aquatic products are highly susceptible to spoilage and deterioration during storage. This not only affects the stability and sustainability of the supply chain for aquatic products but also has a negative environmental impact, including pollution and resource wastage2,3. The proliferation of microorganisms is one of the primary causes of spoilage in aquatic products. Spoilage bacteria, such as Pseudomonas, Shewanella, and Enterobacter, produce metabolites like ammonia and hydrogen sulfide by breaking down proteins and fats, leading to tissue degradation and the development of off-odors4,5. Specific spoilage microorganisms and compounds that negatively impact aquatic products are presented in Table 1. Lipid oxidation in also occurs in aquatic products under aerobic conditions, generating aldehydes and ketones that contribute to off-odors and a reduction in nutritional value6,7. Additionally, the autolytic action of endogenous enzymes, particularly proteases that degrade myofibrillar proteins, further accelerates the softening and spoilage of aquatic products, even under frozen conditions, where enzymatic degradation continues at a slower rate8,9. Enzymes that accelerate the process of deterioration are presented in Table 2. Therefore, safe and effective preservation technologies that extend the shelf life of aquatic products are required to maximize the retention of their nutritional and monetary value. When the bacterial counts reach or exceed 107/g, fish will begin to exhibit signs of spoilage, manifested as off-odors and off-flavors10,11. Specific compounds that negatively impact safety and quality also begin to emerge in spoiled fish11. A linear regression model has been previously publish provided an accurate prediction of the shelf life of fish and is presented below12.

In the model, DT represents detection time, DT0 represents the DT value at the cut-off quality threshold (the rejection phase) and dDT/dt0°C is the daily rate of change in DT for fish stored at 0 °C.

Low-temperature refrigeration is the most common method for preserving aquatic products due to its simplicity and low cost13. Refrigeration can largely maintain the integrity of the appearance of aquatic products but may lead to some degree of reduction in the level nutritional components and a decline in quality when the product is thawed14. Chemical preservation extends the shelf life of food utilizing chemical preservatives, and is the most common method used for aquatic product preservation. The use of chemical preservatives effectively inhibits the growth of microorganisms and both exogenous and endogenous enzymes, thereby prolonging the shelf life of aquatic products. However, long-term or excessive consumption of chemical preservatives may adversely affect human health15. Traditional preservation methods, such as salting and drying, are cost-effective and simple to utilize, and can effectively extend the storage period of aquatic products16. However, harmful substances such as nitrates or nitrites may be produced during processing. The chemical reaction that occurs between nitrites and secondary amines can form carcinogenic nitrosamines, which pose a threat to human health17. Additionally, current preservation methods do not completely inhibit the growth of microorganisms and the occurrence of lipid oxidation18.

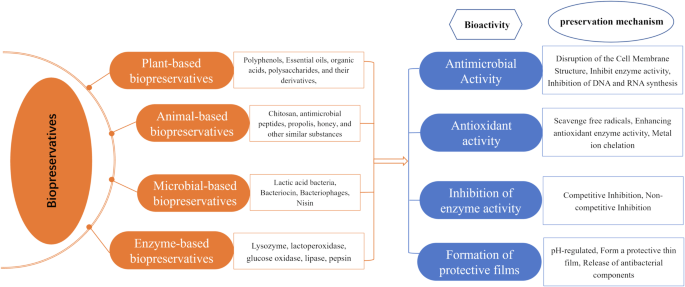

Consumers have become more aware of the potential adverse health effects of chemical preservatives, and so bio-preservation techniques have garnered increased attention. Bio-preservation techniques typically employ natural or microbial-derived preservatives, such as lactic acid bacteria (LAB), bacteriocins, and enzyme preparations19. Relative to traditional preservation methods, bio-preservation avoids the texture degradation associated with low-temperature storage and also inhibits the growth of spoilage bacteria. Consequently, bio-preservation, relative to current methods, better preserves the natural flavor, texture, and nutritional content of aquatic products, extending their shelf life20. Additionally, reducing the use of chemical substances lowers the potential risk of environmental pollution. Animals, plants, and microorganisms are common sources of bio-preservatives that exhibit good antibacterial and antioxidant properties, and which can be used to maintain the freshness of aquatic products and extend their shelf life21. Essential oils (EOs) obtained from plants effectively delay spoilage, reduce nutrient loss, and extend the shelf life of aquatic products22. Bio-preservatives such as LAB, bacteriocins, and bioactive peptides also have also been demonstrated to be effective for the preservation of fish and seafood23. Notably, different types of aquatic products (brackish and freshwater species) exhibit significantly different responses to bio-preservatives due to their inherent characteristics and ecology. However, the knowledgeable selection and combination of bio-preservatives can address these differences and be used to enhance the preservation and maintain the quality and safety of aquatic products24,25.

The present review summarizes the latest advancements in using essential oils, polyphenols, chitosan, bacteriocins, and other bio-preservatives to maintain the quality and extend the shelf life of different types of aquatic products. The review discusses the mechanisms underlying the antimicrobial, antioxidant, and enzyme-inhibitory effects of bio-preservatives. The synergistic effect between bio-preservation techniques and other preservation methods is also discussed, as are the main issues and solutions associated with current bio-preservation technologies. The aim of the review is to provide a factual reference for the application of bio-preservation technologies for the storage and preservation of different types of aquatic products.

Commonly employed bio-preservatives and their utilization in the preservation of aquatic products

Bio-preservatives are bioactive substances obtained from other organisms, including LAB, as well as lysozyme, essential oils, plant polyphenols, and chitosan, that effectively inhibit microbial growth, delay spoilage, and maintain the freshness of aquatic products26. Aquatic products, especially those derived from brackish vs. freshwater species, vary in their response to bio-preservatives.

Plant-based bio-preservatives

Plant-based bio-preservatives are increasingly used in food preservation and processing industries, driven by consumer demand for natural products and environmentally-friendly processing. Commonly utilized plant-based bio-preservatives include EOs, polyphenols, and other plant extracts that vary in their bioactive activity, which include antioxidant, anti-microbial, anti-autolysis, and other types of activity. Several studies have demonstrated that EOs exhibit antioxidant, antiseptic, antimicrobial, antiviral, antifungal, and insecticide activity27. Major components of EOs, such as cinnamaldehyde and thymol, have shown inhibitory effects against a wide range of bacteria and fungi, thus, indicating that EOs represent an effective bio-preservative28. Notably, bacteria in saline environments are difficult to control with conventional chemical preservatives. However, the volatile components of essential oils can penetrate bacterial cell membranes due to their lipophilic nature and exhibit a strong inhibitory effect against salt-tolerant bacteria29. Huang et al.30 reported that treatment of Lateolabrax japonicus fillets with basil essential oil at 4 °C significantly reduced colony counts, and the level of total volatile basic nitrogen (TVB-N) and thiobarbituric acid (TBA), extending the shelf life of filets from 6.0 days to 12.8 days (113% increase). Additionally, Wang et al.31 demonstrated that 0.025% oregano essential oil effectively inhibited the growth of cold-tolerant Mycobacterium species in tuna, thereby extending its shelf life. The level of effectiveness of EOs varies in different types of aquatic products, with greater antibacterial activity observed in marine fish relative to freshwater fish. Huang et al.32 demonstrated that the use of a 2% oregano EO film for the preservation of grass carp slices stored at 4 °C significantly inhibited the growth of Aeromonas and Shewanella bacteria, extending the shelf life of the carp slices from 6 days to 8 days (33% increase). This result is consistent with previous research findings33. The variable effect on EOs may potentially be explained by the high microbial diversity found in freshwater fish, relative to saltwater fish. Although EOs have strong antibacterial properties, they often need to be used in combination with other preservatives to achieve the highest level of effective preservation.

Polyphenols are another a class of plant secondary metabolites that exhibit bio-preservation activity. Polyphenols have been generally shown to inhibit the proliferation of pathogenic bacteria while enhancing the growth of probiotic bacteria34,35. Polyphenols are antioxidant metabolites that are commonly found in many plants, where they effectively scavenge reactive oxygen species (ROS) and prevent lipid oxidation. Due to their antioxidant properties, polyphenols can inhibit the oxidative spoilage of aquatic products36,37. Notably, the treatment of saltwater fish with polyphenols can significantly delay the oxidation of fats due to the higher content of unsaturated fatty acids in the muscle tissue of saltwater fish, relative to freshwater fish, thereby protecting the quality of the fish meat38. Radhalakshmi et al.39 found that application of 5% and 10% concentrations of Piper betel (Piper betle) leaf extract effectively reduced the rate of lipid oxidation in tuna meat and inhibited the growth of Staphylococcus aureus and Escherichia coli, thus extending tuna shelf life. However, the composition and content of fatty acids in freshwater fish differ from saltwater fish, rendering the antioxidant effect of polyphenols less of a major component of bio-preservation activity, than the direct inhibition of microbial growth. Therefore, the application of polyphenols for the preservation of freshwater fish is typically combined with the use of other bio-preservatives, such as nisin, to enhance the level of bio-preservation40.

Other plant extracts, including organic acids and polysaccharides, also exhibit a level of bio-preservation activity against bacteria, as well as antioxidant properties41,42,43. Organic acids are naturally present in various fruits, including ascorbic acid in oranges, tartaric acid in grapes, malic acid in apples, and citric acid in lemons23. Pickling of aquatic products with acetic, lactic, malic, and tartaric acids at pH levels ranging from 3.7 to 4.2 resulting in Baltic herring products exhibiting varying degrees of shelf life and quality44. Ascorbic acid is commonly used for the preservation of freshwater aquatic products, such as rainbow trout, silver carp, and freshwater shrimp (Macrobrachium rosenbergii). Its use extends the shelf life of these products by lowering their pH, which inhibits the activity of proteases and lipases produced by microorganisms45,46,47. Polysaccharides are bio-macromolecular carbohydrate polymers composed of >10 monosaccharide units linked together by glycosidic bonds. In addition to serving as a fundamental component of plant cell walls, they also contribute to the normal physiological function of organisms and have antioxidant, antibacterial, and prebiotic activity that are useful for the preservation of food48. In this regard, algal polysaccharides have excellent antibacterial and antioxidant properties that can effectively extend the shelf life of aquatic products. Rainbow trout coated with algal polysaccharides and stored at 4 °C were reported to have a shelf life that was extended from 6 days to 16 days (167% increase)49. Additionally, Xiao et al.50 also reported that polysaccharides inhibit ice crystal growth in frozen mandarin fish (Channa argus) fillets, thereby maintaining the quality of the fish meat. The main applications of plant-based bio-preservatives in prolonging the shelf life of aquatic products are summarized in Table 3.

Animal-based bio-preservatives

Animal based bio-preservatives are defined as natural substances extracted from animal sources that can be used to prevent microbial growth, inhibit spoilage, and extend the shelf life of food products. Indeed, the application of animal-based bio-preservatives on aquatic products has been shown to effectively maintain product quality, prolong storage time, reduce the use of chemical preservatives, and thus enhance food safety and nutritional value51. Chitosan is a natural polysaccharide derived from shellfish, that exhibits significant antioxidant, antibacterial, biocompatible, and enzyme inhibitory properties52. Chitosan is also an excellent film-forming material and can be used to form a protective layer over food products that functions as a physical barrier, effectively reducing food spoilage53. Soares et al.54 utilized 0.5% and 1.5% chitosan coatings on frozen Atlantic salmon (Salmo salar) and found that the 1.5% concentration was more effective in maintaining the color of the fish meat and preventing microbial contamination. Another study reported that treating grouper (Epinephelus spp.) fillets stored at 4 °C with a 0.5% chitosan-poly (lactic acid) (PLA) film extended their shelf life from 7 days to 9 days (28% increase) and reducing the levels of Enterobacteriaceae, Pseudomonas, Aeromonas, and Vibrio bacteria significantly better than a 1% and 2% chitosan-PLA films55. Plant-based bio-preservatives are often combined with chitosan films or coatings as composite preservatives to extend the shelf life of aquatic products. Chitosan is particularly effective in inhibiting the growth of spoilage bacteria, especially Gram-positive bacteria, in marine species, such as tuna and salmon56. Researchers have modified chitosan with various phenolic acids, including hydroxybenzoic, gentisic, protocatechuic, caffeic, and ferulic acids, and found that they effectively preserve the quality of sea bass (Lateolabrax japonicus) during refrigerated storage57. More specifically, a chitosan-gentisic acid copolymer was found to extend the shelf-life of sea bass by up to 9 days58. Treating salmon (Salmo salar) stored at 5 °C with chitosan films containing grape seed extract and carvacrol microcapsules (CMF) effectively inhibited the growth of psychrophilic bacteria and Pseudomonas species. The glossiness of the salmon was well maintained and the shelf life was extended by 4–7 days59. The application of chitosan on freshwater fish needs to consider the lower salinity environment. The muscle of freshwater fish contains a higher fat content, which may reduce the antibacterial efficacy of chitosan and require the use of higher concentrations. Nawaz et al.60 treated slices of South Asian rohu (Labeo rohita) stored at −18 °C with (0.5%, 1%, and 2%) concentrations of chitosan and found that the 1% concentration group was the best in maintaining the quality and sensory properties of fish meat. A previous treatment of grass carp stored at 2 °C with a 1.5% chitosan solution combined with 0.25% concentrations of lemon and thyme EO effectively reduced lipid oxidation, maintained fish meat quality, and extended the shelf life to 16 days61.

In addition to chitosan, lactoferrin, antimicrobial peptides (AMPs), propolis, and other substances of animal origin have also been utilized as antimicrobial agents62. These substances have been recognized as safe bio-preservatives. Lactoferrin, a member of the transferrin family with an average molecular weight of approximately 80 kDa, is present in most mammalian secretions, including tears, milk, and saliva63. The ability of lactoferrin to reduce iron content in its surrounding environment provides potent antimicrobial activity, effectively inhibiting a broad spectrum of Gram-negative and Gram-positive bacteria, fungi, and parasites under neutral pH and refrigeration conditions62. The application of propolis and its extracts in the preservation of aquatic products primarily focuses on freshwater species such as catfish and rainbow trout. Propolis contains various antibacterial compounds, including hydrogen peroxide and phenolic compounds, which inhibit the growth of many species of microorganisms, prevent lipid oxidation in aquatic products, and thus help to maintain their flavor and nutritional value64,65. Ucak et al.66 investigated the preservative effect of 2%, 8%, and 16% concentrations of propolis extract in a gelatin film on refrigerated rainbow trout fillets. Results demonstrated that a 16% propolis extract significantly inhibited the growth of Gram-negative psychrophilic bacteria and Enterobacteriaceae, and effectively reduced the rate of lipid oxidation, compared to the untreated group. In that study, the shelf life of rainbow trout fillets was extended from 6 days to 12 days (100% increase), relative to the untreated control. AMPs are generally considered safe and effective bio-preservatives that can be incorporated into packaging materials. A MOp2-loaded thiolated chitosan-stabilized Pickering emulsion had a significant inhibitory effect on the growth of Escherichia coli and Staphylococcus aureus, as well as a reduction in pH, TVB-N, and color values67. The combination of the AMP with chitosan extended the shelf life of grass carp (Ctenopharyngodon idella) to 9 days when stored at 4 °C67. Recent applications of animal-based bio-preservatives in prolonging the shelf life of aquatic products are summarized in Table 4.

Microbial-based bio-preservatives

Microbial-based bio-preservatives refer to technologies that utilize microorganisms or their metabolic products to enhance the safety and quality of aquatic products and extend their shelf life. Microbial-based or derived bio-preservatives have received considerable attention in recent years. Researchers are utilizing antimicrobial compounds produced during fermentation to identify and produce bioactive compounds that not only extend the shelf life of food but also maintain their freshness and color68. Microbial preservatives reduce pathogen establishment and growth by producing inhibitory compounds, organic acids, and carbon dioxide, etc.69. Bacteriocins constitute a heterogeneous category of AMPs, typically consisting of 20-60 amino acids, that are ribosomally, synthesized They are protein-based toxins that inhibit the growth of other bacteria and can be absorbed by the human body70,71. Freshwater fish species, such as carp, grass carp, and silver carp, harbor common spoilage bacteria, including Pseudomonas, and Enterobacteriaceae72. Most of these bacteria are prefer a neutral or slightly alkaline pH and are are also sensitive to bacteriocins. The treatment of vacuum-packed rainbow trout stored at 4 °C with nisin (100 μg/g) significantly inhibited the growth of Gram-positive bacteria, preserved the nutritional quality of fish lipids, and extended the shelf life of the trout from 12 days to 16 days (33% increase)73. Some studies have shown that nisin has reduced activity under high-salt conditions, while other halophilic bacteriocins, such as pediocin, exhibit higher activity in high-salt environments and can effectively inhibit the growth of halophilic bacteria on the surface of saltwater fish74,75,76. Yin et al.74 reported a pediocin ACCEL treatment was more effective in inhibiting the growth of Listeria monocytogenes than nisin in seafood stored at 4 °C storage. Bacteriocins also exhibit strong antibacterial activity against Staphylococcus putrefaciens in raw fish slices, inhibiting their growth, reducing muscle degradation, and extending their shelf life76.

Bacteriophages, also known as bacterial viruses, are widely present in ocean water, soils, potable water, and food77. The genetic material of these bacterial viruses comprises either DNA or RNA that is encapsulated within a protein capsid78. Bacteriophages are divided into two categories, namely lytic and lysogenic bacteriophages, with lytic bacteriophages being the most commonly used in preservation79. Bacteriophages exhibit a high level of species specificity, enabling them to potentially target specific microbes without interfering with the composition of the overall microbial community and without altering food sensory characteristics. Bacteriophages attach to specific target bacteria, inject their DNA or RNA into the host cell cytoplasm through their molecular tails, replicate, and utilize the ribosomal lytic enzymes (endolysins) produced by host cells to induce cell lysis and ultimately inhibit the growth of specific bacteria80,81,82,83. Moreover, bacteriophages are stable under a wide range of temperature and pH conditions, making them suitable for use in diverse food processing environments77,84. Hernández85 reported that treating fresh mackerel fillets stored at 6 °C (with a maximum storage time of 6 days) with a high concentration of phage AZT6 (multiplicity of infection (MOI) of 350:1) effectively killed 90% of the Serratia population, demonstrating their significant antibacterial effect. Notably, the antibacterial efficacy was positively correlated with phage dose with low MOI phage treatments had no significant effect on the Serratia population. Phages used in freshwater aquatic products require strong adaptability and the ability to maintain good activity under the conditions present in a freshwater environment. Yang et al.86 isolated and characterized a new lytic phage (SPMIX3-156) that was found to significantly inhibit the growth of Shewanella baltica and Streptococcus gallolyticus in catfish at 4 °C. This indicates that SPMIX3-156 has broad potential application for use in the preservation of freshwater aquatic products. Gram-negative bacteria are common spoilage bacteria in freshwater fish. In this regard, the phage PD1 has been shown to significantly inhibit the growth of Pseudomonas fluorescens in refrigerated grass carp, effectively extending its shelf life87.

Reuterin is an antibacterial compound produced by lactic acid bacteria88. It reacts with fungal and bacterial proteins and nucleic acids resulting in the disruption of cellular structure and function. Reuterin also compromises the integrity of microbial cell membranes, inducing electrolyte leakage and thereby inhibiting microbial growth89. Montiel et al.90 demonstrated that reuterin (10 AU/g) significantly inhibits the growth of Listeria monocytogenes in cold-smoked salmon stored at 8 °C, thereby enhancing the safety of this product. Additionally, the application of reuterin on cold-smoked salmon subjected to high hydrostatic pressure (HHP) treatment at 450 MPa for 5 minutes, enhanced its level of food safety and prolonged its shelf life91. The use of reuterin in the preservation of aquatic products is expected to increase with further research into its mechanisms of action and application. Recent studies on the use of microbial-based bio-preservatives to prolong the shelf life of aquatic products are summarized in Table 5.

Enzyme-based bio-preservatives

Enzymes are produced and found in the tissues of all living organisms and in some cases secreted outside of cells. Therefore, this review presents an overview of enzymes as a biological preservative separately in a distinct section, despite playing a role in the activity of other bio-preservatives, especially microbial-based bio preservatives. Given the well-documented antibacterial, and antifungal activity of different enzymes, they have the potential to be used to inhibit the growth of microorganisms that degrade aquatic products and prevent spoilage92. Numerous enzymes are currently available for use in food preservation, including lysozyme, peroxidases, oxidases, lipases, pepsin, and others93. Aquatic products from saline environments, such as fish, mollusks, and crustaceans, have evolved salinity tolerance. The types and concentrations of free amino acids in their muscle tissues differ significantly from freshwater aquatic products and can affect the efficacy of enzymatic bio-preservatives.

Lysozyme, a food-grade antimicrobial enzyme, possesses bacteriostatic, bacteriolytic, and bactericidal properties92. It is particularly effective against Gram-positive bacteria due to its ability to hydrolyze the β-1,4-glycosidic bonds found in the polysaccharide layer of the cell walls of Gram-positive bacteria94. However, the efficacy of lysosyme against Gram-negative bacteria is significantly reduced due to the presence of a protective lipopolysaccharide layer94. Even so, lysozyme can effectively control the growth of a wide range of food pathogens. Notably, a range of environmental factors, including pH, temperature, salt concentration, and osmotic strength, can affect the stability and antimicrobial activity of lysozyme. These limitations constrain the use of lysozyme in food preservation. Therefore, lysozyme is frequently utilized in conjunction with other bio-preservatives and/or novel preservation techniques to enhance its ability to maintain food quality during storage. Lysozyme conjugated with perilla leaf oil and packaged in nanoparticles to form an emulsion was shown to exhibit effective bactericidal activity, and reduce the pH, total viable count (TVC), and TVB-N in salmon (Salmo salar) stored at 4 °C, extending the shelf life of salmon by at least 6 days95. An active coating of gum tragacanth (GT) and sodium alginate (SA) infused with epigallocatechin gallate and lysozyme, was shown to be effective as a fish preservative. This formulation improved the quality and extended the shelf life of large yellow croaker (Larimichthys crocea) stored at −3 °C for at least seven days96. Additionally, an appropriate concentration of transglutaminase was reported to promote protein cross-linking in aquatic products, enhancing their structural stability97. Spraying slices of refrigerated mackerel (Scomber scombrus) with different concentrations of transglutaminase (1, 4, 7, and 10 units/gram) revealed that a concentration of 7 units/gram provided the best inhibition of coliform bacteria and yeast-mold, helping to maintain the texture and flavor of the fish slices98. Recent applications of enzymes-based bio-preservatives in prolonging the shelf life of aquatic products are summarized in Table 6.

Notably, the combined use of different biological preservatives can have unexpected effects. Research has demonstrated that when chitosan is utilized as an edible film for preservation, the incorporation of plant extracts (such as cinnamon and tea polyphenols) can enhance the preservative properties of the chitosan film (CS)99. Green tea extract (GTE) infused into a chitosan film enhances the antioxidant capacity of the film and also improves its capacity to prevent water loss100. Another study also reported that the addition of tomato extract to chitosan films extended the shelf life of Sierra fish fillets by at least five days (33% increase)101. The combination of chitosan and essential oils has been shown to reduce surface oxidation in aquatic products and inhibit microbial growth, thereby prolonging shelf life and maintaining sensory properties102. Notably, chitosan nanoparticles (CNP) loaded with fennel (Foeniculum vulgare) EO were reported to extend the shelf life of Huso huso fish fillets from 9 days to 18 days (100% increase)103. Similarly, when bacterial extracts are infused in chitosan film, it serve as a protective barrier that helps to maintain the sensory characteristics of aquatic products and extend their shelf life. Other studies have reported that chitosan films infused with nisin can prolong the shelf life of carp fillets by 8 days (50% increase)104 and the shelf life of large yellow croaker (Pseudosciaena crocea) by 8 days (50% increase)105, by its ability to inhibit microbial proliferation and maintain sensory properties. Research has also demonstrated that the incorporation of lactoperoxidase into chitosan solutions can extend the shelf life of trout fillets by at least 4 days (33% increase)106.

The mechanisms underlying the preservation of aquatic products by bio-preservatives

Inhibition or eradication of spoilage microorganisms

Bio-preservatives have excellent antimicrobial activity. The available space for spoilage bacteria is reduced when the structure of the microbial communities is optimized for healthy species of microbes, which inhibits the growth and reproduction of pathogenic species. Bio-preservatives also affect the structure and function of cell membranes of spoilage bacteria, increasing membrane permeability and thus compromising the integrity and functionality of bacterial cells. Plant-derived EOs are composed of a variety of chemical compounds, including phenols, alcohols, ketones, and ethers107. EOs can significantly inhibit the growth of spoilage bacteria in aquatic products due to their antimicrobial and antioxidant properties108. EOs can disrupt cell walls and cytoplasmic membranes by releasing lipopolysaccharides, resulting in the breakdown and leakage of intracellular compounds, effectively suppressing the activity of most Gram-negative and Gram-positive bacteria109,110. EOs also inhibit bacterial enzyme systems, such as ATPase and protein synthesis enzymes, thereby interfering with normal bacterial metabolism. Studies have shown that thyme and cinnamon EOs effectively inhibit the growth of Escherichia coli and Staphylococcus aureus. They also exhibit an inhibitory effect against Pseudomonas aeruginosa and Salmonella Typhimurium111,112. EOs also interfere with ion transport processes and interact with membrane proteins and other intracellular compounds, which inhibits the growth of spoilage bacteria113,114. Nisin is a naturally occurring antimicrobial peptide that effectively kills or inhibits Gram-positive bacteria, such as Clostridium botulinum and Listeria, that cause food spoilage, and also has a strong inhibitory effect on Bacillus species115. Nisin inhibits oxidative rancidity and microbial growth in refrigerated sea bass fillets by interfering with bacterial nucleic acid and protein synthesis, extending their shelf life by three days116. Nisin can also interact with lipopolysaccharides on the bacterial cell membrane surface, causing membrane disruption and increased permeability, ultimately leading to cell lysis117. A combination of 0.6% nisin and 1% chitosan was shown to inhibit the growth and biofilm formation of Shewanella putrefaciens and Shewanella algae, thereby reducing the accumulation of TVB-N, cadaverine, and other spoilage products in aquatic products118. In summary, plant-derived EOs and nisin inhibit the growth of spoilage bacteria such as Shewanella putrefaciens, Bacillus, and Pseudomonas by disrupting cell membranes and interfering with the synthesis of nucleic acids and proteins.

Antioxidant activity

Some bio-preservatives also have antioxidant properties that through various mechanisms, such as scavenging reactive oxygen species (ROS), slowing down free radical chain reactions, enhancing the activity of antioxidant enzymes, and chelating metal ions, help to maintain the quality of aquatic products. Tea polyphenols are a group of phenolic compounds extracted from tea leaves that possess abundant phenolic hydroxyl groups, rendering them excellent hydrogen or electron donors. They effectively bind free radicals and form stable phenoxyl radicals, which slows free radical chain reactions and inhibits oxidative enzyme activity119. Tea polyphenols also enhance antioxidant enzyme activity in cells and form complexes with metal ions, thus inhibiting oxidative processes120. the addition of 1% tea polyphenols to a high-fat diet increases the activity of antioxidant enzymes such as superoxide dismutase (SOD), catalase (CAT), and GSH-Px in the serum and liver of hybrid groupers, thereby enhancing their antioxidant capacity121. Tea polyphenols also increase antioxidant capacity by regulating the Nrf2 signaling pathway and simultaneously stimulating the NF-κB and MAPK pathways122. The addition of 50 mg/kg of tea polyphenols to the diet of juvenile tilapia (Oreochromis niloticus) significantly increased serum acid phosphatase (ACP) and T-AOC activity, elevated the expression of CPT1α in liver tissues and achieved a survival rate to approximately 90%123. Chitosan chelates ferrous ions in fish, preventing their conversion to ferric ions and thereby preventing their ability to catalyze the generation of free radicals, which diminishes oxidative processes124. One study demonstrated that high molecular weight chitosan and its flavonoid derivatives act as scavengers of 1,1-diphenyl-2-picrylhydrazyl (DPPH) radicals, effectively increasing antioxidant capacity125. Chitosan has all been shown to increase the concentration of non-enzymatic antioxidants, such as vitamin C and vitamin E, which increase the antioxidant capacity of cells126. Chitosan also reduces serum-free fatty acids and malondialdehyde concentrations, while enhancing the activity of antioxidant enzymes such as SOD and CAT127. In summary, tea polyphenols and chitosan function as antioxidants that scavenge free radicals, enhance antioxidant enzyme activity and regulate antioxidant-related metabolic pathways.

Inhibition of enzyme activity

Bio-preservatives inhibit enzyme activity through competitive inhibition and non-competitive inhibition. Polyphenolic compounds that are present in many plants have the ability to form stable complexes with enzyme substrates and metal ions128. This interaction alters the active state of the enzyme which affects its function and activity. Anthocyanins are as a plant-derived extract that reversibly binds to tyrosinase, α-glucosidase, and dipeptidyl peptidase-4 even in the absence of an appropriate substrate, which inhibits enzyme activity129,130. Research has shown that bilberry anthocyanins, alter the structure of α-glucosidase and α-amylase through non-competitive inhibition, thereby affecting their catalytic activity131. Catechins regulate MAPK and COMT pathways and inhibit receptor tyrosine kinase activity, thereby altering their function and altering cellular metabolism132. Sae-Leaw et al.133 reported that catechins and their derivatives inhibit polyphenol oxidase activity, which prevents melanosis in refrigerated Pacific white shrimp. Catechins also inhibit the activity of trimethylamine-N-oxide demethylase, which extends the shelf life of frozen squid134. Quercetin, a plant-derived extract, effectively inhibits DNA gyrase135. It also suppresses the activity of two enzymes crucially linked to oxidative processes, namely, acetylcholinesterase (AChE) and butyrylcholinesterase (BChE)136. In summary, polyphenolic compounds, such as anthocyanins, significantly inhibit the activity of several enzymes, including α-glucosidase, AChE, and BChE, and regulate related metabolic pathways. The properties of antioxidant compounds effectively extend the shelf life of aquatic products.

Formation of protective films

Bio-preservatives play a crucial role in maintaining the quality and extending the shelf life of aquatic products. This is achieved through mechanisms such as pH regulation, inhibition of microbial growth, and the formation of protective films. Citric acid lowers the pH of aquatic products, creating an acidic environment unfavorable to microorganisms137. The low pH environment inhibits the growth of spoilage bacteria, which extends the shelf life of aquatic products138. Combining electrolyzed water with 1% citric acid significantly reduced Aeromonas counts in Largemouth bass fillets, thus extending their shelf life139. Citric acid also coagulates proteins on the surface of aquatic products resulting in the formation of a protective film. The film prevents the free exchange of air and moisture, which inhibits the growth of spoilage bacteria140. Grapefruit seed extract contains naringenin, a natural compound with antibacterial activity that inhibits the growth of spoilage bacteria in aquatic products141. Grapefruit seed extract forms a protective film on the surface of aquatic products. The active compounds in grapefruit seed extract interact with the surface microbial cells which inhibits their growth and reproduction. Sodium alginate is a polysaccharide derived from algae that has a unique gel-like structure that can form a protective film on the surface of aquatic products142. The alginate film effectively blocks the free movement of air and moisture, which inhibits the growth of spoilage bacteria143. The strong water solubility and gel-forming properties of sodium alginate effectively inhibit bacterial growth and contribute to the quality maintenance of rainbow trout fillets and refrigerated Megalobrama amblycephala144. In summary, citric acid, grapefruit seed extract, and sodium alginate inhibit the growth of spoilage bacteria and maintain product quality forming a protective film on the surface of aquatic products. The mechanisms underlying the activity of bio-preservatives in aquatic products are shown in Fig. 1.

Mechanisms underlying the preservation of aquatic products by bio-preservatives.

Integration of bio-preservation techniques with other preservation methods

Combining bio-preservatives with nanotechnology

Nanostructures of edible materials are fabricated using non-toxic, economical, and readily available natural polymers that combine both hydrophilic and lipophilic substances with antibacterial and antioxidant properties. Such materials include nanoparticles, nanoemulsions, and nanocomposites, which have been shown to enhance product shelf life145. The use of nanostructured antibacterial agents includes polymeric nanoparticles, nano-liposomes, nanofibers, etc.146.

Chitosan nanoparticles(Cht-NP), as a polymer-nanoparticle with both surface and interface effects, quantum size effect, and small size147, exhibit outstanding structural, physicochemical, and biological characteristics148,149. The antimicrobial properties of Cht-NP are significantly greater than natural chitosan. This is primarily attributed to their increased positive charge, which enables interaction with microbial surfaces and internal components (DNA, RNA enzymes, etc.), which negatively impact growth and survival147,150. The positive charge of Cht-NP interacts with the negative surface charge of S. typhimurium, altering cell membrane structure and negatively impacting cell functions151,152. Meanwhile, chitosan-loaded EOs at 150 µg/mL completely degrade biofilm structure and formation in Acinetobacter baumannii and effectively eradicates it153. Nano-liposomes are a nanoscale phospholipid vesicle bilayers154. They have high wrapping efficiency, stability and biocompatibility. Nano-liposomes are used to manufacture nanocapsules, which can then be loaded with antiseptics, antioxidants, and surfactants155. Nanocapsules loaded with EOs significantly reduce microbial community growth of thermophilic bacteria, which extends the shelf life of meat from 13 to 15 days156. Soy lecithin encapsulation of nisin was reported to have good physical stability and antimicrobial efficacy157. Nisin significantly inhibits the initial exponential growth of bacteria. Nano-liposomes adsorbed on the cell surface slowly release nisin into microbial cell through endocytosis, significantly extending the inhibitory effect of nisin against Listeria monocytogenes ATCC 7644158. Nisin, as a positively charged polypeptide, neutralizes the charge of nano-liposomes, fostering the binding of nano-liposomes and the uptake of nisin into bacteria cells, thus enhancing the antimicrobial effect of nisin159. Cellulose is produced by plants and represents a natural, renewable biopolymer160. Cellulose microcrystals isolated from various types of natural cellulose are referred to as nanocellulose (CNC)161. Thin films made of chitosan and CNC are used to package meat162. CNC improves the thermal stability of chitosan films. The positive charge of chitosan interacts with the negative charge on the surface of microbial cell membranes, altering the permeability of microbial cell membranes, and resulting in microbial death and the extension of the shelf life of aquatic products.

Combining bio-preservatives with ozone technology

Ozone technology is used to extend the shelf life of foods163. Ozone kills bacteria, viruses, yeasts, fungi, and insect larvae through its ability to oxidize essential components of cells164. The shelf life of Pacific oysters treated solely with chitosan is 14–15 days, however, the combined treatment of chitosan and ozonated water extends the shelf life to 20–21 days165. Washing food products with ozonated water followed by the application of a chitosan coating significantly reduced microbial counts in raw shrimp, compared to treatment with ozone or chitosan coating alone. The combined treatment was reported to inactivate 6-log CFU/g of L. innocua and natural bacteria on the surface of raw shrimp166. Tea polyphenols are used to preserve meat and fish due to their strong antibacterial and antioxidant properties167. Combining a prewash with ozonated water followed by a tea polyphenol coating significantly improved the sensory attributes of black sea bream, including muscle color. which is the primary determining factor in consumer acceptance of the product168. A combined prewashing with ozonated water and a tea polyphenol coating significantly reduced microbial community populations, lipid oxidation, and protein decomposition in black sea bream, which extended their shelf life169. S. putrefaciens is a major bacteria responsible for the degradation of sarcoplasmic and myofibrillar proteins in bighead carp (Aristichthys nobilis)170. S. putrefaciens has also been reported to play a predominant role in the spoilage of large yellow croaker171. Ozonated water combined with tea polyphenols inhibited the growth S. putrefaciens, reducing its ability to induce endogenous oxidative stress172. The high antimicrobial activity of EOs can be partially attributed to their hydrophobic or hydrophilic properties173. However, the strong flavors and odors associated with EOs have prevented their widespread acceptance and use as bio-preservatives174. However, EOs combined with an ozone treatment decreased processing time, and contributed to maintaining the sensory characteristics of products175. Exposure to 10 ppm ozone for 15 min) combined with a mixture of EOs and 1.6% citrus extracts extended the shelf life of fish fillets from 7 to 21 days by reducing microbial growth176. Additionally, the combined treatment of ozone and 0.1, 0.3, or 0.5% carvacrol significantly reduced the population of S. enterica from 6 log CFU/g to <10 CFU/g without altering sensory characteristics177.

Combining bio-preservatives with irradiation technology

Irradiation (IR) is a method that involves exposing food to ionizing radiation to inactivate microorganisms178. The main source of ionizing radiation used for food treatment is the radioisotope cobalt-60 (Gamma radiation). IR destroys DNA chemical bonds and alters cell membrane permeability, which negatively impacts a wide range of cellular functions179. IR combined with EOs improves the antibacterial efficacy because IR enhances the infiltration of EOs into cells180. Gamma irradiation (1 kGy) combined with a mixture of EOs and citrus extract (1.6%) improved the shelf life of fish fillets from 7 days to > 28 days by reducing microbial growth, which improved product quality and safety176. Combining IR (1 kGy) and a 0.5% coating of rosemary EO significantly decreased the population of S. aureus, Enterobacteriaceae, and B. cereus in fish fillets, extending their shelf life181. IR (3 kGy) combined with rosemary EO completely eliminated the microflora present in fish fillets181. Gamma irradiation decreases the fiber curvature of chitosan derived from horseshoe crabs, resulting in chitosan with a more compact crystalline structure182. Notably, after gamma irradiation, chitosan possesses more alkyl (-NH) and hydroxyl (-OH) groups than prior to irradiation182. The additional -NH and -OH groups creates bonds that require a greater amount of microbial metabolic energy to degrade183. High dose (20 kGy) irradiation combined with horseshoe crab chitosan extended the shelf life of marine meats to at least 15 days184. Similarly, IR combined with nisin had a greater antibacterial effect than the use of nisin alone185. Nisin has been reported to have no significant antimicrobial activity against Gram-negative Escherichia coli in beef186. However, γ-irradiation (3 kGy) alone significantly decreased the population of Escherichia coli187. Notably, the antimicrobial effect of γ-irradiation (1 kGy) is significantly enhanced when combined with nisin188. Combining γ-irradiation and nisin significantly reduced the total bacterial count in chicken meat and inhibited the mold and yeast growth. The combined treatment also increases the level of antimicrobial activity against Bacillus cereus and Escherichia coli189.

Combining bio-preservatives with low-temperature technology

Low-temperature storage has always been considered the most effective method for the long-term preservation of food, including fish and other seafood. Although low temperature arrests chemical reactions and microbial proliferation, enzymatic and non-enzymatic reactions still occur at low rates. Food stored at freezing temperatures may also damage the texture of the food product due to the loss of tissue water caused by the formation of ice crystals190. Most carnobacteria species are psychrophilic, which means they can grow and reproduce at temperatures ranging from −10 °C to 20 °C. LAB increase their production of bacteriocins under low-temperatures. Bacteriocins exhibit the highest level of antibacterial activity against Escherichia at temperatures below −20 °C, and their lowest activity at ambient temperatures (28 ± 2 °C)191. The reduction of lactic acid production at low-temperatures also increases the pH of the environment while a low pH reduces protease activity, which improves the shelf life of food products. Different bacteriophages were shown to effectively lyse Salmonella, Clostridium difficile and diarrheagenic E. coli192. Bacteriophages can coexist with fermenting microorganisms during biological preservation processes193. They utilize endolysins to break down the peptidoglycan layer of specific bacteria, leading to the lysis and death of those targeted bacteria193. Bacteriophages can survive under low-temperatures194. In this regard, the ability of bacteriophages to lyse Salmonella cells was demonstrated at low-temperatures195. Wang et al.196 conducted experiments using a single phage with multiplicities of infection (MOIs) of 104 and 105 at 4 °C, targeting four Salmonella serotypes, achieving reductions of up to 1.3 and 2.3 log10 units, respectively. In summary, low temperatures improve the antimicrobial activity of LAB and bacteriophages. Low temperatures also increase the production of bacteriocins in LAB, as well as the ability of bacteriophages to lyse Salmonella cells. Combining bio-preservatives with low-temperature technology significantly extends the quality and shelf life of aquatic products.

Combining bio-preservatives with coating technology

Edible coatings (EC) are defined as thin layers of edible materials covering food surfaces that are considered part of the food product. The major benefits of EC include the ability to provide extra nutrients, and waste reduction, as the film is consumed with the food product197. EC can exhibit antimicrobial activity, enhance the sensory properties, act as a barrier to external elements (including moisture and air), physically protect food, prevent dehydration, and extend product shelf life198. Early studies focused on the use of EC (such as alginate) to support the growth of yeasts used to prevent food decay199. The survival rate of probiotic bacteria is enhanced in edible films, and the combined use of ECs with beneficial bacterial strains that have antimicrobial properties, extends the shelf life of food products200. Adding probiotic bacteria and green tea to films provides an additive effect in the control of spoilage microbes and extends the shelf life of hake to more than a week201. LAB can also be added to edible coatings to control pathogens in foods systems197. LAB inhibit the growth of pathogens through competition for space and nutrients, or by producing antimicrobial compounds202. Notably, new properties of edible coatings are being discovered as the development of nanotechnology progresses145. The addition of clove extract to Cht-NP significantly decreased the abundance of S. typhimurium in shrimp198. Carvacrol-loaded chitosan-tripolyphosphate nanoparticles (Np-EO) also controlled microbial growth in carrots, and extended their shelf life203. Encapsulating betasitosterol in nanostructured lipid carriers (NLCs) provided a significant enhancement of antioxidant properties in the film and the nutritional quality of butter204. Importantly, ECs significantly reduce the negative impact of EOs on product flavor and allow for the slow time release of EOs which extends their bio-preservative activity and extends the shelf life of the food product205.

Principal issues and countermeasures concerning the use of bio-preservatives for aquatic products

Although bio-preservation methods are considered more advantageous than traditional preservation methods, there are still issues that need to be addressed. Regarding plant-based bio-preservatives, plant extracts and EOs are usually used for the preservation of meats206. However, higher concentrations or longer treatment times are required for seafood and this can affect sensory qualities, including color, odor, flavor, and taste207. EOs extracted from herbs and spices have an especially strong aroma even at low concentrations208. The potential alteration of sensory qualities by these compounds limits their application in seafood209. Importantly, combining EOs with an ozone treatment can reduce the concentration needed and shorten treatment time, mitigating negative impacts and enhancing consumer acceptance175. EOs also possess unique flavors (spicy, floral, and herbal tastes). For example, jasmine EO has a strong spicy aroma210. Therefore, high concentrations of EOs can alter the original flavor and taste of the target food product, adversely affecting the sensory attributes of the food and making it less acceptable to consumers. However, different essential oils vary in their effect on different foods. For example, thymol is more suitable for use on spice-added foods211, as it does not alter the sensory characteristics of the food while extending its shelf life. Overall, it is important to select essential oils that do not affect the sensory quality of the targeted food product and control their concentration in food products. In contrast to EOs, chitosan does not promote changes in the sensory characteristics of aquatic products. In fact, chitosan generally enhances the sensory attributes of seafood, including appearance, color, texture, taste212,213, and especially odor and flavor214. This is accomplished by chitosan preventing the growth of spoilage and pathogenic microorganisms, reducing lipid oxidation, and moisture loss in seafood. Chitosan can also reduce the negative alterations of food quality in fish by microorganisms by inhibiting the formation of by-product compounds and stabilizing the pH of fish products215. Its application in seafood preservation also helps reduce total volatile basic nitrogen (TVB-N) levels by inhibiting microbial growth215,216, and in general improves the texture profile of fish, including attributes such as hardness, whiteness, and cohesiveness217.

Traditional methods used to extract plant compounds are time-consuming and often use large amounts of solvents, which increases production costs218. Additionally, phenolic compounds in plants are present in relatively low concentrations and easily degraded by light and heat, which reduces their bioactivity219. New technologies, such as enzyme-assisted extraction (EAE), supercritical CO2, and ultrasound-assisted extraction (UAE), have the potential to increase the yield of extract while reducing costs and should be explored220,221. EAE, utilizes enzymes to break down plant cell walls, promoting the release of phytochemicals222,223.

Despite the notable advantages of the various bio-preservation methods discussed in this review, pressing issues remain that will require a resolution. Some plant-based preservatives, such as EOs, while exhibiting significant potential as a bio-preservative, are significantly constrained from industrial applications due to their distinctive aromatic profiles224. From a practical standpoint, this problem necessitates the selection of specific EOs for specific food products, with the objective of mitigating any undesirable aromatic influences imparted by the EO. It is also imperative to strictly regulate the concentration of the EO utilized to minimize the potential for eliciting allergic reactions when the product is consumed Chitosan, distinguished by its exceptional film-forming capabilities and its status as an edible and biodegradable material, has found widespread application in food preservation. However, the efficacy of utilizing chitosan alone, either in the form of a film or a coating, remains limited225. Furthermore, the poor solubility of chitosan in water and most organic solvents limits its application in the food industry, biomedicine, and agriculture226. Consequently, it is customary to incorporate nanocomposites or other bio-extracts in chitosan-based coatings or films used for bio-preservation, to enhance the efficacy of the chitosan coating or film.

Chitosan is widely used as an external coating for the preservation of aquatic products due to its strong film-forming ability2. However, chitosan is easily dissolved in acidic solutions, which may lead to protein precipitation, loss of water-holding capacity, and the generation of a sour taste2. Compounds present in seafood, such as fats and proteins, may interact with chitosan, reducing its antioxidant and antibacterial properties227. To address this problem, the use of ozone to prepare chitosan reduces the use of acetone and NaOCl, and eliminates chemical waste228. Chitosan can be industrially manufactured from shellfish by-products to control costs229,230.

Bacteriocin is one of the most commonly used microbial-based bio-preservatives that is recognized as safe for human consumption231. The main factors limiting the application of bacteriocin as a preservative in food are its low yield and high production cost232. The high cost of production is mainly due to the expense of the nitrogen nutrient, obtained from beef, yeast, and peptone extracts, required for the fermentation process233. Importantly, protein residues are present at the end of fermentation and need to removed in the subsequent extraction and purification processes. The concentration of the culture medium also affects the yield of bacteriocins. A lower concentration leads to rapid nutrient depletion, while a higher concentration inhibits bacterial growth, resulting in reduced yield234. Collectively, the data indicate that the growth activity of LAB that produce bacteriocins can be enhanced by optimizing the culture medium formula, including adjusting the carbon to nitrogen ratio, to optimize the production of bacteriocin234,235. Importantly, industrial waste materials, such as molasses, soy, and hydrolyzed wheat flour, can be utilized as low-cost nitrogen sources to reduce production costs236,237. Bacteriocins are also affected by pH238. Introducing acid-tolerant genes or over-expressing genes in the lactic acid synthesis pathway may also enhance bacteriocin production by increasing the tolerance of LAB strains to acidic conditions239. The primary limitation in using bacteriophages in food preservation is the lack of understanding of their genetic mechanisms. Some strains may possess toxicity, and there use may also foster the emergence of phage-resistant strains of pathogenic and spoilage bacteria193. Therefore, it is essential to thoroughly understand the underlying mechanisms (genetics and toxicity) used by bacteriophages to lyse bacterial cells to assure their safe use240.

Enzymes can be used for food preservation. However, their antibacterial activity sharply declines under high-temperature conditions241. Most enzymes also exhibit bacterial specificity. For example, lysozyme has a significant antibacterial effect on Gram-positive bacteria, but weak against Gram-negative bacteria242. The short half-life of lysozyme in solution significantly affects its antibacterial efficacy243. Therefore, measures must be found to address these problems. In this regard, combining lysozyme with Cht-NP significantly improved its thermal stability and efficacy under high temperatures244. Loading lysozyme in N-succinyl chitosan (NSC) can enhance its antibacterial activity at low concentrations245. Ionotropic gelation to encapsulate lysozyme in chitosan nanoparticles (LZ-NP) was also reported to increase the half-life of lysozyme246.

Regulations & safety

Among current preservation technologies, biological preservation is considered one of the most reliable, as it can extend the quality and shelf life of food in a hygienic state, and with minimal nutritional loss247. Some plant EEOs and extracts have been listed as Generally Regarded as Safe (GRAS) by the United States Food and Drug Administration (FDA) and can be used to improve food safety and enhance or diversify its aroma, while serving as a food preservative248. While direct application to the skin may cause allergic contact dermatitis in some individuals, low concentration of EOs do not possess skin-sensitizing properties and are therefore considered safe. One study demonstrated249 that the use of a mixture of two herbal essential oils, curry leaves. and cloves, at rates of 0.1 ppm and 0.2 ppm, extend the shelf life of food products without any sensory impact250. Chitosan derived from shellfish, has also been shown to be a biocompatible and non-toxic natural polymer that can be used alone or in combination with other methods for food preservation. No lethal effects were observed when mice were fed chitosan at a high dose of 2000 mg/kg251. Shrimp-derived chitosan was recognized as GRAS by the FDA ss early as 2012, and studies have shown that chitosan extracts do not trigger allergic reactions in individuals with shrimp allergies252. Most bacteriocins used commercially are produced by the fermentation of lactic acid bacteria (LAB), such as Lactobacillus acidophilus. Notably, protease-degradable bacteriocins have also been recognized as a GRAS compound62. Nisin, a type of bacteriocin, has been approved by the European Union for use in food preservation (EU Directive 1129/2011/EC)253. ListexTM P100 and LMP102 bacteriophages were approved by the FDA in 2006 for controlling Listeria monocytogenes contamination and approved in 2010 for use on meat, fish, poultry, vegetables, and some dairy products to extend shelf life254. The SalmofreshTM bacteriophage was approved by Health Canada in 2014, for use on all foods for the control of Salmonella255.

There is little evidence to indicate that enzyme-containing products pose an allergy risk to consumers. Enzymes are not considered to be the direct cause of primary skin sensitization or contact dermatitis256,257. According to the European Union Scientific Committee on Food (SCF) guidelines, enzymes from (edible) plant or animal species do not pose health concerns. Lysozyme (E1105), lactoperoxidase, and thrombin, among others, have been approved for use by the European Union[14]. Approximately 50 enzymes have been approved for use as food additives or recognized as GRAS by the FDA258. Notably, enzymes are listed as processing aids in most countries and cannot be directly added to food as additives to achieve the purpose of extending shelf life. Differences in existing legislation and safety assessment requirements, widespread scientific uncertainty, and the emergence of new production technologies are the main reasons for the varying standards.

Other factors that constrain the industrial application of biological preservatives are closely tied to the regulatory frameworks of various nations. According to the FDA of the United States, EOs are generally regarded as GRAS compounds and can serve as potential substitutes for synthetic additives259. The regulations on the use of bacteriocins also vary between countries. Bacteriocins were classified as GRAS compounds by the United States. FDA in 1988260. In Denmark, bacteria used for the production of food additives must not produce toxins or antibiotics261. However, in the United States, there is no need to specifically consider the type of bacteriocin as long as it is recognized as GRAS262. Importantly, when a purified bacteriocin is utilized as a food preservative in the U.S. A., it is automatically recognized as GRAS260, although the FDA may require justification for this classification.

Summary & outlook

There has been a significant surge in consumer demand for bio-preservatives, i.e. naturally derived compounds sourced from plants, animals, and microorganisms. The growing preference is driven by consumer desire for greater natural, health-conscious, and environmentally sustainable dietary options, which has encouraged the exploration of natural products capable of effectively preserving the safety and quality of aquatic products. The focus on bio-preservatives not only addresses consumer demands but also aligns with broader environmental and sustainability goals, and fostered advancements in the preservation methods used on aquatic products. This review provides information on the wide range of bio-preservatives that are available, derived from diverse sources, and exhibiting a variety of preservation properties. Bio-preservatives have the capacity to inhibit or eliminate spoilage bacteria, reduce degradation resulting from oxidative and enzymatic activity, and form protective films that prevent contamination of food products by spoilage bacteria. The efficacy of individual bio-preservatives, however, is inherently limited. Therefore, enhancing efficacy and reducing any adverse effect of bio-preservatives often necessitates combining complementary technologies, including nanotechnology, ozone technology, and coating technology, among others.

The use of bio-preservatives still faces many industrial and application challenges. Additional research is needed to identify and optimize appropriate combinations of bio-preservatives that will enable the industry to overcome the present barriers that preclude the widespread and effective use of bio-preservatives on aquatic products on a larger scale. Artificial intelligence (AI) should be utilized to construct an intelligent monitoring system for real-time surveillance of various parameters (temperature, humidity, oxygen concentration, etc.) in the product storage environment, and automatically adjust preservation strategies based on real-time data263. Using AI for predicting equipment failure and instigating preventive maintenance measures would ensure the stable operation of preservation equipment and reduce preservation failures and product losses due to equipment malfunctions. Leveraging machine learning algorithms to analyze historical data combined with real-time data would allow the continuous optimization of preservation strategies, and foster improved preservation outcomes and longer extensions of product quality, safety, and shelf life264. The development of intelligent packaging materials used in conjunction with AI would allow for the real-time monitoring of the internal environment of packaged food products and enable adjustments in packaging properties, such as permeability and moisture retention, as needed to meet the optimal requirements of different food products. In this regard, the cross-disciplinary integration of AI and biotechnology is leading to advancements in intelligent packaging.

Large-scale processing of bio-preservatives from raw materials can be problematic. Therefore, it is imperative that research efforts focus on the extraction of these substances at an industrial scale. Research should also be conducted to identify new, novel bio-preservatives to diversify available product offerings and enhance the efficacy of bio-preservatives used on aquatic products. Furthermore, research efforts should be designed to find ways to mitigate the minor and major adverse effects associated with the use of bio-preservatives. These factors include nonuniform coating, extended drainage times, and alterations in taste. While bio-preservatives are typically considered safer than chemical preservatives, further empirical research is necessary to rigorously validate these claims. This includes comprehensive investigations into their safety and the feasibility of uniform product standards.

Glossary

The glossary and explanation of key terms in the review are shown in Table 7.

Responses