The implementation of blockchain adoption in China’s manufacturing industry: the technology organization environment (TOE) method

Introduction

Blockchain technology allows for the decentralization of transaction data storage while maintaining consistency. It also develops a shared and distributed database of transactions between the related parties to increase transparency, safety, and effectiveness (Goldman Sachs, 2016). According to a survey report on blockchain technology compiled by Deloitte, respondents showed a high degree of positivity regarding blockchain technology’s capacity. Subsequently, 83% of the respondents opined that not adopting blockchain technology would put their employers’ competitive interests at risk. In spite of these significant expectations, 54% of respondents described blockchain technology as “overhyped” (Pawczuk et al., 2020). Regardless of the industry’s high expectations for blockchain technology, the issue of an inadequate understanding of the subject should not be avoided. Therefore, the methods for shifting this technology from the “hype” to practical architecture should be a significant concern in the future (Mulligan et al., 2018).

In the manufacturing industry, blockchain technology can create new value, as reflected by increased collaboration between competing companies, information sharing within large networks, secure storage location for critical information, improved trust and efficiency through smart contracts, and faster and more cost-efficient product delivery. All of these make products more traceable while streamlining the financing process, and enhancing coordination among buyers, suppliers, and banks (Gillai & Mendelson, 2020; Gaur & Gaiha, 2020).

In particular, the majority of research works have emphasized a noticeable improvement in the limited blockchain technology from the privacy or security viewpoint (Han & Fang, 2024). However, many of the suggested solutions have revealed the inadequacy of a thorough assessment of its efficacy as well as obstacles associated with blockchain scalability. In the case of the current manufacturing and supply chain management sector, the majority of the research on blockchain technology has highlighted the descriptive or theoretical hypotheses (Treiblmaier, 2018; Saberi et al., 2018; Schuetz & Venkatesh, 2020; Janssen et al., 2020; Pu & Lam, 2021; Liu et al., 2023), case analysis (Kshetri, 2018; Perboli et al., 2018), interviews (Di Gregorio et al., 2017; Caldarelli et al., 2021; Toufaily et al., 2021), and the quantitative analysis of causality (Queiroz & Wamba, 2019; Kamble et al., 2019; Queiroz et al., 2020; Wamba et al., 2020; Karamchandani et al., 2020; Wong et al., 2020a; Wong et al., 2020b; Abed, 2020; Khalil et al., 2021; Liang et al., 2021; Li et al., 2021; Yousefi & Tosarkani, 2022). It can thus be seen that the blockchain remains in the phase of development, in which a wide range of behavioral, organizational, and technical challenges take place (Karakas et al., 2021). Policy orientation issues may also arise as it progresses towards the application phase (Crosby et al., 2016; Lemieux, 2016). Therefore, this research was established as an empirical analysis of blockchain’s implementation in the manufacturing sector. A causality questionnaire was also employed to help fill the gap in the literature.

An increasing quantity of research work addressing the acceptance, choice, dissemination, or implementation of new technologies (e.g., information technology and associated systems) has become associated with information management (Salahshour Rad et al., 2018). Such research work has also featured the Theory of Reasoned Action (TRA) (Ajzen & Fishbein, 1980), the Theory of Planned Behavior (TPB) (Ajzen, 1991), the Technology Acceptance Model (TAM) (Davis, 1989), the Unified Theory of Acceptance and Use of Technology (UTAUT) (Venkatesh et al., 2003), the Diffusion of Innovation (DOI) Theory (Rogers, 1983), and the Technology-Organization-Environment (TOE) Framework (Tornatzky & Fleischer, 1990) among others.

Theories including the TRA, TPB, TAM, and UTAUT to a certain degree emphasize the cognitive and attitudinal acceptance or selection behavior of individual decision-makers toward new technologies. Furthermore, DOI theory and TOE investigate the implementation of new technologies from an organization’s viewpoint at the organizational level (Martins & Oliveira, 2010; Oliveira et al., 2014; Haneem et al., 2019). Several studies on the implementation of blockchain technology adopt the TAM model (Liu & Ye, 2021) or the UTAUT model (Wong et al., 2020b), while other studies adopt the TAM and TOE models (Kamble et al., 2021). Several other studies have applied the TOE model (Wong et al., 2020a; Ganguly, 2024). In this research, the implementation of blockchain technology is highlighted based on the viewpoint of the manufacturing industry at the individual level. For this reason, the TOE model has been implemented on a theoretical basis (Orji et al., 2020; Wong et al., 2020a). To illustrate, the TOE has been widely used at the organizational level to investigate the motives and results from the organizations’ adoption of new technologies, including information technology and systems, e-business systems (Awa et al., 2015), radio frequency identification (RFID) (Wang et al., 2010), and enterprise resource planning (ERP) (Awa & Ojiabo, 2016).

In recent years, discussion has revolved around new technologies under the TOE framework, including Cloud Computing (Gangwar et al., 2015), Augmented Reality (AR) (Chandra & Kumar, 2018), the Internet of Things (IoT) (Tu, 2018), Big Data Analytics (BDA) (Chen et al., 2015), 3D printing (Yeh & Chen, 2018), Software-as-a-Service (SaaS) (Tomás et al., 2018) and artificial intelligence (AI) (Richey et al., 2023) among others. However, the investigation into blockchain technology in the Chinese manufacturing industry based on the TOE framework is inadequate. Therefore, this research aims to fill this gap by investigating the main elements impacting the implementation of blockchain technology in the manufacturing sector. This approach should help in further understanding the adoption of new technology from the point of view of the Chinese manufacturing industry.

Over the past few decades, China has been rapidly progressing in the development of its inland regions to draw in foreign investment, with Sichuan Province attracting the most foreign direct investment. Prominent multinational organizations including Acer, Cisco, Foxconn, IBM, Intel, Kingfisher, Microsoft, Onsun, and Sony have established factories in Sichuan. Approximately 247 of the world’s top 500 organizations have invested in Sichuan, making it a prominent industrial manufacturing base in the world (HKTDC, 2022).

This research aims to investigate the implementation of blockchain technology by Chinese manufacturers in Sichuan through the TOE model. Following this Introduction, Section 2 highlights the available literature, and presents the research hypotheses. Section 3 illustrates the research methodology, and Section 4 provides the outcomes from the empirical analysis. Section 5 discusses the results of the study, as well as its theoretical contributions, implications, and limitations for future reference. The article ends with the conclusions of the study in the final section.

Theoretical model and hypotheses

The adoption of blockchain technology

Salahshour Rad et al., 2018 combined five variables that were widely employed in the literature following 330 research works on the implementation of IT from 2006 to 2015. These variables were the Intention to Use, Adoption, Actual System Use, Continuance of Use, and Mixed Use of Variables. Most notably, the Intention to Use was the variable most frequently used in research works, as reflected in 199 out of the aforementioned 330 studies. Furthermore, several researchers pointed out that the factors determining the intention to use are distinct from the actual behavior in most cases, which has led to further distinctions.

Adoption was second in terms of being the variable most emphasized, as indicated in 53 of the 330 research works. In this research, blockchain technology adoption was highlighted as one of the primary variables related to organizations instead of people (Wamba et al., 2020). In general, the rate of blockchain technology implementation in China’s manufacturing industry has been insignificant. Numerous organizations, however, will have the opportunity to engage with blockchain technology in the future. In measuring the implementation of blockchain technology in the manufacturing industry, the covariate selected in this research denotes the question of adoption employed by Thiesse et al. (2011) and Oliveira et al. (2014).

Technology-organization-environment (TOE) framework

The Technology-Organization-Environment (TOE) framework is an organization-level theory illustrating the impact of the Technological, Organizational, and Environmental dimensions on the application and procedures of technology innovation implementation (Tornatzky & Fleischer, 1990; Wong et al., 2020a; Orji et al., 2020). The technology dimensions denote the internal and external technologies employed in the organization. Several technologies are present in the market, with some being employed (Baker, 2012). On the one hand, the organizational dimensions denote the factors reflecting a company, including the size and scope of the organization, formalization, centralization, and complexity of the management structure, the number of redundant internal resources, and the standard of human resources. On the other hand, the environmental dimensions reflect an organization’s industries, competitors and partners, and government policies or aims (Tornatzky & Fleischer, 1990). Accordingly, We further discuss these in the following three subsections.

Technology

Tornatzky and Klein (1982) investigated the association of innovation attributes with implementation in a 75-paper meta-analysis. As a result, compatibility, relative advantage, and complexity were recorded with the strongest association with innovation implementation (Tornatzky & Klein, 1982). Wang et al.’s (2010) investigation into the factors of RFID implementation among the top 1000 manufacturing organizations in Taiwan brought to light the complexity and compatibility of the technology dimensions as the primary elements that strongly impact RFID adoption.

In terms of the technology dimensions, Ahmadi et al. (2017) stated that comparative advantages, compatibility, and security concerns have a significant impact on a hospital’s implementation of its Hospital Information System (HIS). Many adopters exhibited their awareness of the advantages of this technology. Apart from that, innovative technologies with higher suitability had a higher possibility of being embraced by potential adopters. Meanwhile, security concerns were perceived as a major barrier to HIS implementation, considering that information security and privacy account for the common issues in the healthcare industry. Overall, this research reached the conclusion that the technology dimensions comprised three primary factors influencing the implementation of innovative technologies, namely, relative advantage (RA), compatibility (CB), and security concern (SC).

Rogers (1983) highlighted the direct and indirect advantages to an organization that introduces new technology. Specifically, the direct advantages comprise increased operational effectiveness, improved data precision and safety, stronger yields, and higher product quality. Meanwhile, the indirect advantages comprise higher customer fulfillment, enhanced corporate image and business partnerships, and a stronger competitive advantage of the organization. In the adoption of blockchain as an innovative technology, benefits including a higher transaction speed, enhanced safety of transaction records, reduced costs of decentralized management, and increased effectiveness may increase the organization’s preparedness to implement blockchain technology (Clohessy et al., 2019; Agi & Jha, 2022). Blockchain technology also offers a secure platform for distributing product sources and data with trading partners and customers, offering product excellence, and strengthening customer loyalty. Blockchain applications including digital bills of lading and smart contracts are able to remove or decrease the paperwork related to today’s business (Dobrovnik et al., 2018). Accordingly, the following hypothesis was proposed:

H1: Technological dimensions positively increase a manufacturer’s adoption of blockchain technology.

Organization

Organizational dimensions are described based on the resources present to support the implementation of innovation. An organization either aids or restricts the implementation of innovation through specific factors: firm size (FS), top management support (TL), and technological competence (TR), which have also been found to be the substantial influencing elements in numerous research works (Oliveira et al., 2014; Wang et al., 2016). Clohessy et al. (2019) demonstrated that an organization’s size and top management support are the substantial elements in the organizational dimensions that impact the implementation of modern communication technologies by small and medium-sized enterprises in rural regions of the United States. To illustrate, abundant resources are available in larger organizations for investment in technology. Meanwhile, top management’s inspiration and dedication to innovation in small organizations are crucial for obtaining adequate resources and support for implementing innovation. Organization size is also considered to be a crucial determinant of blockchain implementation. Extant research works and industry reports have indicated that large firms are more likely to implement blockchain technology compared to small or medium-sized firms (Clohessy et al., 2019).

According to Gutierrez et al. (2015), technology competence has significantly impacted the decision to adopt cloud computing in the organizational dimensions. Of particular note, top management support is highly important for the provision of resources needed for the development of cloud services. In this case, senior managers are responsible for the application of cloud computing (Gutierrez et al., 2015). Top management support is also responsible for blockchain implementation. Furthermore, the implementation of blockchain technology possibly requires new regulatory rules, and is significantly complex, as it involves acquiring new resources, the incorporation of resources, transactions between firms, information exchange, and the advancement of new expertize and capabilities. Accordingly, it could be indicated that decision-making by the top management is required in the operational approaches to the implementation of this technology (Clohessy et al., 2019).

Technology competence denotes the technology infrastructure supporting the business related to the innovative technology, while IT human resources refers to the IT professionals with the understanding, experience, and expertize in the implementation of innovative technology. In general, organizations with higher technical knowledge and expertize show more possibilities of considering the adoption of technological innovations (Wang & Wang, 2016). Accordingly, the following hypothesis is suggested:

H2: Organisational dimensions positively increase a manufacturer’s adoption of blockchain technology.

Environment

The environmental dimensions are represented by the environment where an organization carries out its business. They involve the stakeholders, including the industry members, suppliers, customers, competitors, and the government among others. It is worth noting that these stakeholders impact the organization’s awareness and decisions related to the need for innovation and may reinforce or disrupt technological innovation (Angeles, 2015). In general, external pressures have led to organizations’ obligations to accept technology (Leung et al., 2015). Furthermore, the dynamic environmental and competitive situations have encouraged organizations to implement a wide range of innovation types (Angeles, 2015). Pressure from competitors and partners, external support, government policy support or disruptions, and the regulatory environment are the commonly impacting elements recorded in numerous previous research works, which were also found to be substantial (Hoti, 2015; Clohessy et al., 2019). In addition, the concept of government policy is identical to the concept of a regulatory environment.

In examining the growth of e-business in developing and developed nations, Xu et al. (2004) identified the crucial elements impacting its implementation in the TOE framework. It was found that “competitive intensity” and “regulatory environment” were substantial elements impacting its implementation in light of the environmental dimensions. Therefore, the regulatory environment has more of an impact on developing nations compared to developed nations due to the information asymmetry and immaturity of the market.

A study by Li (2008) examined the key elements for the implementation of e-procurement in the Chinese manufacturing industry. It was found that external pressure and external support were the primary factors determining e-procurement implementation in this industry. In this study, external pressure comprised two aspects: 1) pressure from competitors, and 2) pressure from suppliers or trading partners. Moreover, numerous Chinese manufacturing organizations lacked the willingness to utilize e-marketplaces or third-party trading platforms for e-procurement. Their urgency to build their e-procurement platforms led to a greater need for external support.

In the environmental dimensions, the study stated that “competitive pressures” and external support were the crucial elements impacting the implementation of modern communication technologies by small and medium-sized enterprises in rural communities in the United States. Considering that the acknowledgement of the merits of communication technology could be achieved solely with a high quantity of adopters, numerous organizations need their trading partners to use electronic means of making contact to gain the full advantages of technology.

It was found by Wang et al. (2010) that “information intensity,” “competitive pressure,” and “trading partner pressure” in the environmental dimensions were the substantial elements impacting the implementation. This was followed by the suggestion that organizations that implemented RFID faced notably less competitive pressure compared to organizations without this implementation. Furthermore, the organizations that faced higher competitive pressure had a higher possibility of accepting and adopting RFID as their competitors used it as a competitive weapon for profitability. In the same dimension, Gutierrez et al. (2015) also demonstrated that “competitive pressure” and “trading partner pressure” were the most crucial elements impacting the decision as to whether to implement cloud computing or vice versa.

Hwang et al. (2016) investigated the elements impacting the implementation of green supply chains in the semiconductor industry. For a long period, this industry has been represented by the utilization of a high volume of resources and has proved from very early on to support green supply chains. Besides the environmental regulations from the Taiwan Environmental Protection Department, it was found that the semiconductor industry in Taiwan faced strong pressure from government and community groups. In this case, Taiwanese companies should demonstrate compliance with the environmental rules established by foreign governments. However, failure to carry out this action may put the organization at the risk of sanctions, which include a prohibition on product creation and the revocation of export licenses (Hwang et al., 2016).

Ahmadi et al. (2017) elaborated that in the environmental dimensions, external pressures and vendor support have a significant influence on the implementation of a Hospital Information System (HIS) in hospitals. The pressures from competitors have led to the belief in many hospitals that the implementation of an HIS would not only assist them in preventing the loss of competitive advantage in the healthcare industry but would also enhance the image and reputation of hospitals through the improvement in healthcare services. The adequate knowledge and experience possessed by the staff members in adopting HIS would increase the hospitals’ confidence in the entire procedure of adopting the system. Thus, it is important for vendors to equip the staff with training and other supportive measures.

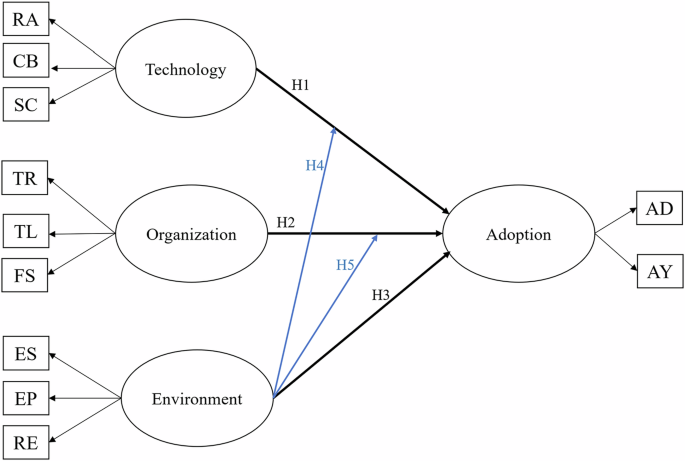

The environmental dimensions comprise three primary elements affecting the implementation of innovative technologies: external pressure, external support, and the regulatory environment. Following the above review of the literature, the following hypothesis was suggested. This is followed by the conceptual research model presented in Fig. 1.

Note: RA, relative advantage; CB, compatibility; SC, security concern; TR, management support; TL, top management support; FS, firm size; ES, external support; EP, external pressure; RE, regulatory environment; AD, adoption situation; AY, adoption year.

H3: Environmental dimensions positively increase a manufacturer’s adoption of blockchain technology.

The moderating role of the environmental dimensions

As previously stated, the environmental dimension comprises external support, external pressure, and the regulatory environment. The environmental dimension denotes the environment where the organization carries out business and involves multiple stakeholders. The pressure and assistance from these stakeholders impact the organization’s decision whether to implement blockchain technology or vice versa. Moreover, the regulatory environment is represented by the government’s provision of business-friendly laws and regulations, encouraging the adoption of blockchain technology by organizations.

Organizational dimensions comprise the organization’s size, top management support, and technological competence. Specifically, the organization’s size is represented by the quantity of workers, capital, and turnover of the organization. The assistance of senior management denotes the promotion and involvement of the organization’s senior executives in the implementation of blockchain technology. The level of technical readiness is described as the organization’s essence associated with blockchain technology, which includes the level of facilities and knowledge.

The technology dimension comprises relative advantage, compatibility, and security concerns. To be specific, relative advantage represents the extent to which blockchain technology is considered to be advantageous to the organization. Furthermore, compatibility denotes the extent to which blockchain technology is compatible with the organization’s operating systems, values, and operations. In addressing the level of conformity with the approach, security denotes the extent of the organization’s belief that the utilization of blockchain technology could achieve adequate security at different levels.

While the TOE framework encompasses the technology, organizational, and environmental dimensions, the environmental dimensions have proved to be the most crucial context that impacts the technology and organizational dimensions (Lu et al., 2021). To illustrate, the Ministry of Industry and Information Technology of the People’s Republic of China (2021) published the “Guiding Opinions on Accelerating the Application of Blockchain Technology and Industrial Development” policy. This policy indicates that the government supports the regional chain and local governments and firms’ investments in the implementation and establishment of blockchain technology. This situation influences the extent to which the firm considers that the implementation of blockchain technology is able to comply with the organization’s current operating system, security mechanism, and mode of operation. It also impacts the promotion and involvement of the senior executives of the firm in the implementation of blockchain technology, followed by the extent of the organization’s ownership of infrastructure and knowledge associated with blockchain technology.

The study by Oliveira et al. (2019) on blockchain and SaaS implementation argued that the environmental dimensions hold higher importance compared to technology competence, SaaS implementation, top management support, and SaaS implementation. By contrast, in Lai et al.’s (2018) study on the elements impacting the enterprise’s attempts to adopt big data analytics (BDA), it was argued that more importance is attached to the environmental dimensions, government policy and rule, and the BDA implementation of competitors. These elements obstruct the technology complexity and top management in terms of supporting attempts to adopt BDA.

It is highlighted in this study that the environmental dimensions moderate the association of technology with the organizational dimensions, including the implementation of blockchain technology. To be specific, the significance of the positive association of the technology dimensions with the implementation of blockchain technology is considered to be relatively more important than the environmental dimensions. Similarly, the significance of the positive association of the organizational dimensions with the implementation of blockchain technology is greater than the crucial part played by the environmental dimensions. Therefore, the following hypotheses have been established:

H4: The association of the technology dimensions with a manufacturer’s adoption of blockchain technology is moderated by the environmental dimensions.

H5: The association of the organizational dimensions with a manufacturer’s adoption of blockchain technology is moderated by the environmental dimensions.

From the above literature review, the TOE model, with its technology dimensions, organizational dimensions, and environmental dimensions being equally important, will positively affect the adoption of related technologies (Kamble et al., 2021; Chaudhuri et al., 2024; Lin, 2024). However, this study puts forward a new view and fills a gap in the literature, believing that environmental dimensions are more important than both technology dimensions and organizational dimensions.

It is then proposed that the environmental dimensions have a positive mediating effect on the relationship between the technology dimensions and their adoption and the relationship between the environmental dimensions and their adoption. (Fig. 1).

Research methodology

Design and sample

The testing of the hypotheses was conducted on 800 manufacturing organizations, followed by their extraction from the database compiled by the Sichuan Provincial Enterprise Technology Center. It is a status granted to particular Sichuan-based firms with solid requirements and capabilities for innovation, including a significant contribution to local innovation and economic growth. Subsequently, of the 511 returned questionnaires, 93 of them showed missing values in several fields. Overall, the collection of 362 valid questionnaires was achieved with a 45.25% response rate, which was similar to that of previous studies conducted in the Chinese context (Li et al., 2020; Subramanian et al., 2015).

Approximately 30% of the respondents held the position of director or deputy manager or higher positions. The remaining 70% of the respondents consisted of operators, administrative staff, and general staff whose responsibilities may include the utilization of blockchain technology in the future. This condition allowed the respondents to possess general knowledge in areas associated with blockchain technology. In the case of the respondents’ personal work experience, more than 60% of them had gained 10 years of experience. Meanwhile, almost 50% of organizations had been operating for more than 20 years, implying that they possessed adequate information to respond to the questionnaire used in this research (Table 1).

Non-response bias

This study evaluated non-response bias by comparing the data from the initial respondents (N = 217) with those who responded after a one-month delay (N = 145), employing the Armstrong and Overton (1977) method to check whether the sample accurately represented the population. An independent t-test revealed that only one factor was significant at the 0.05 level, indicating that non-response bias was negligible and the sample accurately mirrored the population.

Common-method variance

Considering that the data were gathered from a single respondent, perceptual scales were employed to test the hypotheses, and the common method variance (CMV) of the scales was investigated. Several tasks were carried out for the mitigation of the CMV in the survey design phase, followed by the processing of two tests. First, Harman’s one-factor test was performed to test the CMV. Of a total of 31 items, eight factors that accounted for 79.99% of the variance (eigenvalue > 1) were withdrawn. The first factor was represented by 12.08%, which was higher than the 10% cut-off. Confirmatory factor analysis (CFA) was the second factor applied to determine the presence of the CMV (Podsakoff et al., 2003) following the presumption that the CMV was not a cause when the single-factor model was found to have a bad fit with this research data. The findings implied that the model was a poor fit with the data (χ2 = 2209.403, df = 425; CFI = 0.824; GFI = 0.640; AGFI = 0.580; RMR = 0.318; RMSEA = 0.108) in comparison to the measurement model fit index. For this reason, the significance of the CMV was not sufficient to distort the findings.

Measures

The survey conducted in this research involved multiple-item measures for all of the constructs. Subsequently, the conceptual model and questionnaires were found to follow past studies and interviews with a number of blockchain experts. In the case of the multi-item scales, respondents were required to specify the extent of their agreement with the statement on a Likert scale, while the scores influenced the Increases in the underlying constructs. The individual items for each scale are included in the Appendix.

Dependent variables

Adoption involves two items constructed by Thiesse et al. (2011) and Oliveira et al. (2014). These two items are used in this study to develop an understanding of the present state of the respondents’ organizations and their preparedness to implement upcoming blockchain technology. A five-point Likert scale was employed to create an understanding of the implementation of industrial blockchain technology for various measures.

Independent variables

Technology was obtained from 11 items with three dimensions, including relative advantage (RA), compatibility (CB), and security concern (SC). The above-mentioned items were also referred to in Ahmadi et al. (2017), Ghobakhloo et al. (2011), Li (2008), Ifinedo (2011), Pearson and Grandon (2005), Oliveira et al. (2014), Thiesse et al. (2011), Wang et al. (2016), Wang and Wang (2016), and Zhu et al. (2006). A seven-point Likert scale ranging from 1 (strongly disagree) to 7 (strongly agree) was employed to assess the implementation of blockchain technology.

The measurement of organization was carried out using nine items with three dimensions, namely, firm size (FS), top management support (TL), and technology competence (TR). The measurements were developed by Ahmadi et al. (2017), Bhattacharya and Wamba (2018), Chandra and Kumar (2018), Haneem et al. (2019), Li (2008), Lin (2014), Wang et al. (2010), Wang et al. (2016), and Wang and Wang (2016). The respondents were required to present ratings for their firm’s size, top management support, and technological competence. A seven-point Likert scale that ranged from 1 (strongly disagree) to 7 (strongly agree) was employed to illustrate the firm’s profile.

Environment followed a 9-item scale measure with three dimensions, namely, external pressure (EP), external support (ES), and the regulatory environment (RE). The measure was in accordance with Bhattacharya and Wamba (2018), Ghobakhloo et al. (2011), Ifinedo (2011), Li (2008), Lin (2014), Pudjianto et al. (2011), Wang et al. (2016), Wang and Wang (2016), and Zhu et al. (2004). A seven-point Likert scale was applied to present ratings for the blockchain environment, which ranged from 1 (strongly disagree) to 7 (strongly agree).

Research method

Confirmatory factor analysis (CFA) was performed in this research to test the convergent and discriminant validity of every construct and guarantee the reliability of the constructs. The antecedents of the association of technology, the firm, and the environment with the decision to adopt were assessed through structural equation modeling (SEM) (Hair et al., 2013). Subsequently, a hierarchical regression was applied to study the paths of moderation between the model constructs. It was predicted that the moderating impacts of the environmental factor on the manufacturer’s implementation of blockchain technology would be examined. The SPSS 25.0 and AMOS 25.0 statistical packages were employed in this research.

Empirical results

Measurement model

The CFA was conducted to test the uni-dimensionality, content validity, and structural reliability, as illustrated in Table 2. The maximum likelihood method was implemented to assess the convergent validity of each measurement scale. It was found that all indicators for the respective constructs exhibited statistical standardization for factor loadings higher than 0.05, which indicated the convergent validity of the theoretical constructs (Hair et al., 2013). In line with this, the standardized coefficients for each item were found to be higher compared to twice the amount of their respective standard errors. Moreover, the critical ratios exceeded 2.0 (Hair et al., 2013), which was a further indication of convergent validity.

The CFA tests were conducted in accordance with the fit indices of the adjusted goodness of fit index (AGFI), comparative fit index (CFI), incremental fit index (IFI), the standardized root mean square residual (RMR), and the root mean square error of approximation (RMSEA). As a result, the values of χ2 = 1082.065; df = 419; AGFI = 0.798; CFI = 0.935; IFI = 0.935; RMR = 0.061, and; RMSEA = 0.066 were recorded in the initial analysis. This was followed by the removal of six items, namely, RA1, SC1, TR2, TL2, ES2, and EP2 for the adjustment of the good model fit. It could be seen from the CFA results in Table 2 that the congeneric measurement model produced the values χ2 = 452.319; df = 227; AGFI = 0.873; CFI = 0.964; IFI = 0.964; RMR = 0.050; and RMSEA = 0.052, which indicated good fit indices for the main structural model.

A high degree of composite reliability denotes constructs with a significant degree of internal consistency. As demonstrated in Table 3, the composite reliability of the research constructs ranged from 0.66 to 0.95, which reached the recommended reliability value of between 0.6 and 0.7 that is acceptable provided that the other indicators of a model’s construct validity are good (Hair et al., 2013). Furthermore, the average variances extracted (AVE) for RA, CB, SC, TR, TL, FS, ES, EP, RE, and AD ranged from 0.50 to 0.88. Overall, according to Hair et al. (2013) all values were more significant than the suggested minimum value of 0.50.

To evaluate the discriminant validity, a comparison was made with regard to the association between the constructs and the square root of AVE. When the value of AVE for every construct was higher than the shared variance between the constructs, the presence of discriminant validity was proved. As seen in Table 3 below, the square root of the AVE of every construct was higher compared to the association between any pair, which indicated the presence of discriminant validity (Hair et al., 2013).

Hypothesis tests

The testing of the hypotheses was conducted through hierarchical regression procedures, leading to the analytical findings presented in Table 4. To investigate the primary impacts of TEC, ORG, and ENV on ADD, the hierarchical regression technology in Model 1 was tested. It was found that TEC (standardized coefficient = 0.175 p < 0.05), ORG (standardized coefficient = 0.254, p < 0.05), and ENV (standardized coefficient = 0.127, p < 0.05) were positively correlated with ADD. Therefore, H1, H2, and H3 gained support.

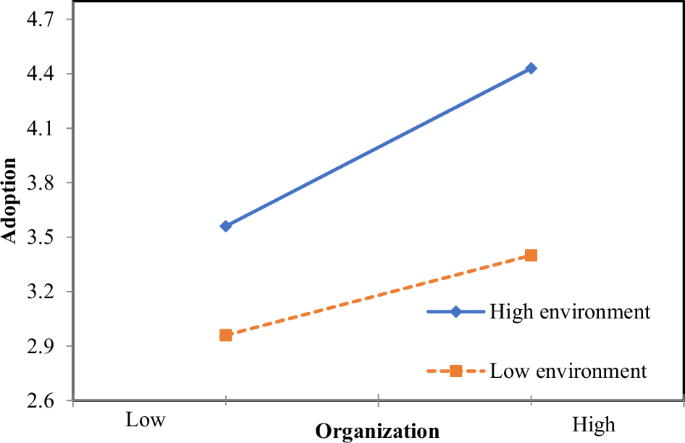

The environment was applied in this study as the moderating variable in Models 2 and 3 to test H4 and H5, respectively. Despite the absence of an interaction impact between TEG and ENV on ADD (standardized coefficient = 0.017, p > 0.05) in Model 2, the interaction impacts between ORG and ENV on ADD (standardized coefficient = 0.123, p < 0.05) were observed when using Model 3. Through this result, it was indicated that H5 was supported instead of H4. Subsequently, both moderating variables were incorporated into Model 4 for investigation. It was implied from the findings that the interaction impacts between TEC and ENV on ADD were insignificant (standardized coefficient = −0.067, p > 0.05). However, a significant interaction was present between ORG and ENV on ADD (standardized coefficient = 0.158, p < 0.05), which proved the outcomes from Model 2 and Model 3. Overall, it was indicated that stronger environmental factors would increase the impact of the company on the application of blockchain technology (Fig. 2).

The moderating effect of the environment on the organization and its implementation.

Discussion

This article has conducted an empirical investigation and has tested the implementation of blockchain technology following the TOE framework. The results provide crucial implications for both theory and practice.

Theoretical contributions

This article makes several contributions to available theories on the implementation of technology. To be specific, this research provides a comprehensive view of the implementation of blockchain technology using a holistic model that includes the company, technology, and the environment as the precedents, while the implementation is included as the result. The studies by Tornatzky and Fleischer (1990), Wang et al. (2016), Ahmadi et al. (2017), and Bhattacharya and Wamba (2018) have been elaborated, followed by the conceptualization of the technological dimensions (e.g., relative advantage, security concern, and compatibility), organizational dimensions (e.g., the organization’s size, top management support, and technology competence), and environmental dimensions (e.g., external pressure, external support, and the regulatory environment) that are pertinent in the implementation of blockchain technology. To be specific, it has been suggested that the elements impacting the implementation of blockchain technology are not mutually exclusive due to the importance of manufacturing organizations taking a range of factors into account when a new technology is implemented.

The implementation of blockchain technology is dependent on the firm’s perceived technological and organizational elements. Most notably, it has also been found that technology, the company, and the environment have directly impacted the implementation of blockchain technology. This condition indicates that the organizations’ viewpoints regarding technological factors, including relative advantage, compatibility, and security concerns, are considered to be the precedents of blockchain implementation. In addition, the organizational elements (e.g., top management support, the firm’s size, and technology competence) have been regarded as the crucial elements impacting the manufacturing organizations’ implementation of blockchain technology. The technology could contribute to relative advantage and has exhibited high compatibility. Therefore, the respondents stated that organizations may implement blockchain technology if it is supported by top management.

The effect of the environment on the implementation of blockchain technology was also examined in this study. It was demonstrated that the implementation of blockchain technology in the manufacturing sector was attributed to environmental elements, including external pressure, external support, and the regulatory environment. Furthermore, there was an expectation that the support granted by the government and external companies would have a positive relationship with the implementation of blockchain technology. In addition, the pressures from partners and customers assisted the manufacturing organizations in adopting and employing the technology. To illustrate, it was observed that the environment played a moderating role in the association between the company and its implementation of blockchain technology. The environment enhanced the impact of the company on the implementation of blockchain technology in the manufacturing sector.

Practical implications

This study has provided three crucial implications for manufacturing organizations. Despite the possibility that blockchain technology and its implications could become significant in business, there have been very few studies on this issue. The results of this study are able to guide IT suppliers, top management, and other suppliers in the development of successful methods to assess the implementation of new technology (e.g., blockchain technology). Based on these results, manufacturing organizations are able to employ the model presented in this research in their assessment of blockchain’s implementation. Besides, when choosing to implement blockchain technology, manufacturing organizations should consider various elements. This research model also provides a thorough overview and discusses the factors influencing the manufacturing organizations’ assessment of blockchain adoption.

In terms of the perceived relative advantages and compatibility, the technological dimensions have been observed to have the most significant positive impacts on an organization’s implementation of blockchain technology. However, the respondents stated that maintaining a high degree of safety and security was the primary factor being considered in the implementation of blockchain technology. This study also found that the organizational dimensions positively impacted blockchain implementation in terms of top management support, the organization’s size, and competence. For blockchain technology to be effectively implemented, manufacturing organizations need to invest in IT-related infrastructure and the reinforcement of their technological capabilities. Moreover, the distribution of resources and adequate education and training are essential in optimizing workers’ and managers’ blockchain expertize, which helps further their understanding of the procedures. The workers and managers could also achieve success in the implementation of blockchain technology.

Finally, the results of this study present the implications for blockchain suppliers that establish and provide services for their clients (e.g., manufacturing organizations). It is suggested that blockchain suppliers formulate successful methods incorporating the mechanisms to boost the organizations’ customers’ viewpoints regarding the relative benefits of blockchain implementation and technology compatibility. In addition, one potential mechanism that enables blockchain technology to be positively implemented is the improvement in the security of data exchange and data protection from hackers.

Limitations and future research

While this research offers useful implications for the introduction of blockchain technology, more studies are needed in the future. To illustrate, the data used in this study were collected from 362 manufacturing organizations in Sichuan Province. Despite the comprehensive approach to data collection in this research, the representation of the manufacturing industry in China through the results was still inadequate. Furthermore, the findings of this research could not be generalized to other types of industries. Provided that the grounds for conducting this study were quite distinct from those of previous research, it was believed that identical outcomes from this study’s model could be tested and applied in other dimensions (e.g., ocean freight carriers, logistics organizations, airlines, hotels, and healthcare).

Other factors, including organizational culture, perceived ease of use, system quality, and user involvement, have the potential to impact the implementation of blockchain technology. It is suggested that these factors be addressed in future studies, followed by an examination of the associations between the TOE and implementation behaviors together with their effect on organizational performance. Moreover, this study has solely examined the model using cross-sectional data (i.e., covering a period of only one year). There is a prediction that changes in the manufacturing environment and technology will occur as more information and new technology are developed in the industry. Thus, it is recommended that the developments in technological factors and implementation behaviors over time be carefully examined. In addition, addressing the practical obstacles in the collection of data on blockchain adoption (e.g., the impact of COVID-19), a mixed-methods approach, including an approach that involves online and social media surveys, may be appropriate for this study.

Conclusions

By implementing the TOE framework, this study conducted an empirical investigation on the factors determining the implementation of blockchain technology in the manufacturing sector. This was followed by the establishment and testing of a blockchain adoption model based on the manufacturing organizations’ evaluation of important precedents, including the technology, the company, and the environment. Technology, the company, and the environment were each observed to have a significant impact on the implementation of blockchain technology in the manufacturing industry. Of particular note, the environment played a moderating role in terms of increasing the company’s impact on the manufacturing organization’s blockchain implementation. Moreover, the model and results presented in this study contribute to the literature by developing a thorough understanding of blockchain adoption behaviors. This study also provides the fundamental framework for future studies on blockchain implementation. This is followed by insights into the manufacturing organizations, which could further the understanding of the factors determining blockchain implementation.

Responses