Trends in polyacrylamide utilization and treatment for hydraulic fracturing

Introduction

Polymers play a crucial role across various stages of hydrocarbon development1,2, including drilling3, reservoir modification4, protection5, enhanced oil recovery (EOR)6, and the rest of production processes7,8. The utilization and treatment of polymers were of interest to both academia and industry. In contemporary extraction operations, hydraulic fracturing (HF) stands as a key technology. Within this domain, polymers, ranging from natural polymers such as guar gum to synthetic counterparts such as PAM, assume critical significance9. A study conducted from September 2008 to August 2014 on 5071 wells in the Marcellus Shale Region revealed that among them, polymers were used 5452 times, with 1770 wells employing guar gum while 644 wells employed PAM in HF10. According to estimates, HF in the U.S. alone consumes approximately 75,000 tons of PAM per year11. As a result of market fluctuations, the reliability of guar gum sourcing has declined, prompting a growing interest in slickwater formulations that primarily utilize PAM as the main component12. Besides, the viscosity of the PAM and its derivatives can withstand high-temperature conditions of up to 240 °C, whereas the viscosity of guar gum declined substantially when the temperature > 100 °C12,13,14.

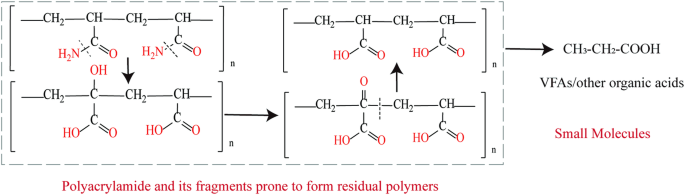

Attention needs to be drawn to the substantial challenges that have arisen in the application and treatment of PAM, especially with the advancement of extraction technology and worsening geological conditions over time, particularly in unconventional, deep/ultra-deep, and offshore extraction points12,15. Residual PAM, as depicted in Fig. 1, in the formation forms filter cakes, leading to pore blockage and reduced permeability, which, in turn, affects production rates16,17, necessitating expensive acidization or other cleaning methods18,19,20,21. HF generates significant flowback and produced water (FPW) containing residual PAM, with concentrations reaching half of the residual PAM in the injected fluid11. PAM is generally considered less environmentally friendly than natural plant-based guar gum and may potentially lead to the release of carcinogenic acrylamide monomers22,23. An acrylamide concentration of 0.06 mg/L is immediately hazardous and a concentration of 150–200 mg/kg could be lethal24. To mitigate the environmental and health threats posed by PAM, the treatment of undesirable PAM is essential. Common methods for treating PAM are membrane filtration25, thermal distillation24, oxidation treatment26, and biological treatments27. However, addressing the challenge posed by PAM remains a pressing issue within the industry.

The figure is modified from Berdugo-Clavijo et al.4

This perspective primarily elaborates on the essential physicochemical properties of PAM and its applications in the oil and gas industry. It also analyzes the advantages and limitations of current treatment methods, emphasizing the necessity for sustainable and cost-effective treatment technologies. Additionally, future directions for sustainable polymer development are underscored. The ultimate goal of this perspective is to raise awareness of the environmental and treatment issues related to PAM in ongoing hydrocarbon development.

Increasing utilization of PAM in HF

PAM plays increasingly important roles in the oil and gas industry. Among a wide range of polymers, PAM, and its derivatives are extensively employed in HF fluid (Table 1). The usage of PAM (5.6–4484 ppm) varies, and that of guar gum (0.01–169430 ppm) is even larger10. An advantage of PAM is that it often eliminates the need for additional crosslinkers or oxidizing breaker agents, due to its versatile functionality, including thickening and friction-reducing capabilities12,14. Compared to guars, PAM exhibits greater elasticity, which enables the transportation of HF fluid at lower viscosities and achieves higher fluid rates of up to 60 barrels per minute during pumping, thereby minimizing potential damage to the formation12. PAM was extensively utilized in HF operations due to its excellent performance, with 98% of the 750 wells investigated in six U.S. states in 2017, and each well consuming an average of 0.2–6 tons of PAM11. Compared to the investigation results of Chen et al.10 from 2008 to 2014, there was a significant increase in the frequency of PAM usage. However, attention must be paid to the potential environmental and production risks associated with PAM.

Extreme operating conditions, such as high total dissolved solids (TDS) and elevated salinity, promote the derivation of distinct PAM derivatives. Hydrolyzed polyacrylamide (HPAM), a derivative resulting from the hydrolysis of PAM, demonstrates significant thickening capabilities in freshwater and at relatively lower temperatures (<75 °C) due to strong intra- and inter-chain electrostatic repulsion of carboxylate groups14. Partially hydrolyzed polyacrylamide (PHPA), consisting of neutral acrylamide and anionic acrylate groups, is suitable for use in water with <25,000 mg/L TDS12,15. Cationic polyacrylamide (C-PAM), copolymerized from acrylamide and substituted acrylate or acrylamide segments, offers an alternative to PHPA and exhibits high stability under high TDS conditions28. Nevertheless, due to the charge screening effect of inorganic cations on carboxylate groups, elevated salinity can induce polymer chain collapse, decrease HPAM viscosity, and impair PHPA crosslink effects12,15.

Changed exploitation spots may exacerbate polyacrylamide treatment challenges

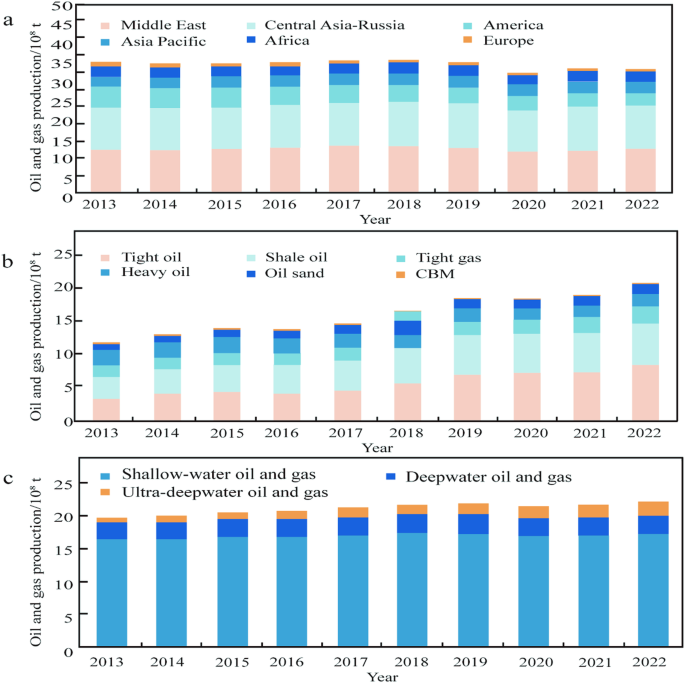

Shifts in extraction spots are expected to increase the application of PAM. Due to the depletion of fossil fuels, there is an ongoing shift in hydrocarbon exploration and exploitation from conventional to unconventional sources, and from onshore to offshore and deep-water sources29,30,31,32. From 2013 to 2022, the total production of conventional oil and gas fields has exhibited a declining trend since 2018 (Fig. 2a)33. As the leading global producer of oil and gas, the U. S. has entered the later stages of conventional gas field development, leading to a noticeable decrease in production. Conversely, unconventional oil and gas field production has steadily increased, surpassing 2 × 109 tons by 2022 (Fig. 2b)33. In China, it is estimated that the production of unconventional natural gas could exceed 50% of the total output by the year 203031. Unconventional reservoirs are often embedded with more extreme environmental conditions, and the extraction of oil and gas from these reservoirs may need the upscaling of reservoir modification and the total amount of chemical uses.

Oil and gas production volume of (a) conventional sources, (b) unconventional sources, and (c) offshore sources. The figure is modified from Wang et al.33.

For unconventional hydrocarbon development, the use of high-volume HF, coupled with water injection for enhanced recovery, results in the consumption of a significant amount of polymers34. Notably, the large-scale massive volume HF, known as “ Ten thousand cubic meters of fluid, one thousand cubic meters of proppants” has become a hallmark of shale gas reservoir modification in China, with the maximum injection volume reaching 88,059 m3,35. The volume of FPW with residual HF chemicals is substantial, which poses significant challenges in treatment36.

The favorable physiochemical properties of PAM may address the challenges of unconventional reservoirs with more extreme operational conditions. The temperature resistance of PAM ranges from 140–240 °C, which is higher than common natural polymers with a range of 140–150 °C13. Reservoirs with high underground temperatures are not uncommon in current hydrocarbon exploitation. For example, in China’s Tarim Basin, where oil and gas reservoirs commonly have depths between 5000–8300 m, high temperatures ranging from 120 to 190 °C, and elevated pressure coefficients of 1.5–2.137. Moreover, with the increasing number of ultra-deep wells reaching depths between 8000 and 9000 meters, the geological conditions of reservoirs become progressively complex, placing enhanced demands on polymer properties38.

PAM exhibits superior drag reduction performance compared to natural polymers, making it more suitable for oil and gas development in unconventional fields. In unconventional hydrocarbon development with significantly high injection volumes of HF fluid, the pump may undergo overwhelming friction when flowing through surface and subsurface pipelines, and thus friction reducers such as PAM are often added to prevent excessive wellhead pressure caused by high friction39. Due to lower porosity and permeability in unconventional oil and gas fields, traditional natural polymers like guar gum, common in conventional fields, show limited friction reduction rates39.

Due to the shift from conventional oil and gas fields to unconventional ones, the treatment of FPW faces more significant challenges. Additionally, the global share of hydrocarbon production from offshore, including shallow water and deep-water reservoirs, has increased40. In 2022, the total production of offshore conventional oil and gas reached 2.24 × 109 tons, accounting for 28.30% of the global total production. This marked an increase of 0.23 × 108 tons, with a growth rate of 1.04% compared to 2021 (Fig. 2c)33. The consistent annual increase in production from ultra-deepwater wells since 2013 suggests that future FPW treatment will need higher and more advanced standards to meet the demands of ultra-deep well operations33. FPW poses a significant threat as a potential source of marine pollution for marine ecosystems40,41. FPW is already the largest by-product in most offshore hydrocarbon development, with the global water cut in offshore oil field production typically ranging from 75 to 80%, and in some wells during the late stages of oil recovery, the water cut may surpass 98%42. The risks have escalated with the increased adoption of offshore HF operations. The treatment challenges could be substantially elevated in offshore operations due to high discharge standards and limited platform space requiring more robust treatment technologies41.

Treatment materials and technologies

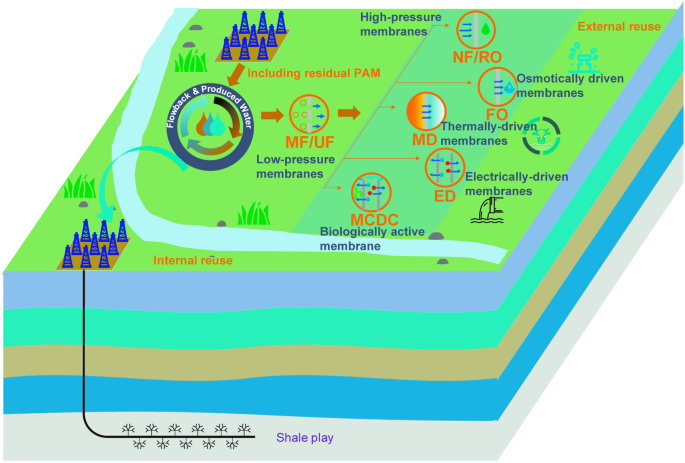

Prioritizing PAM treatment is essential in water management within the oil and gas industry. Adequate treatment of PAM in hydrocarbon development wastewater requires a combination of treatment technologies (see Fig. 3 for a HF wastewater treatment onsite facilities) and treatment standards depend on the source fluids (e.g., drilling fluids, FPW), local regulations, and disposal strategies (e.g., reuse, surface discharge, and deep well injections). Reuse, surface discharge, and deep well injections demand more robust treatment processes to prevent adverse effects on the subsequent HF/water injection, or ground and the underground environment43.

The top left is the filter, the top right is the reservoir, and bottom left and bottom right are settling tanks.

Polyacrylamides are typically addressed through various treatment methods, including membrane filtration, thermal distillation, oxidation treatment, and biological removal (Table 2). Generally, membrane filtration and biological degradation align more closely with sustainable goals.

Mechanical vapor recompression (MVR) of thermal distillation has been employed in the FPW treatment while the applications of techniques: multi-stage flash distillation (MSF), multiple effect distillation (MSD), and vapor compression evaporation (VCE) are limited44. Thermal distillation processes, typically operating around 100 °C, may not effectively remove polymers like PAM, which demonstrate thermal stability even at higher temperatures up to 200 °C24. Besides, thermal distillation imposes high demand on the equipment and space availability and the operating cost and energy consumption could be several times greater than membrane filtration and other methods44,45.

The chemical oxidation method is typically achieved by introducing gel breakers like persulfates or peroxides to reduce recalcitrant polymers such as PAM and other organic pollutants. Ammonium persulfate, potassium persulfate, and sodium persulfate are common oxidants26. The generation of free radicals, crucial for the degradation of PAM and similar polymers, relies on the thermal decomposition of persulfates26. The reaction is slow at temperatures below 51 °C, while at high temperatures, oxidants may degrade too rapidly, resulting in suboptimal gel-breaking effects for PAM26. Moreover, growing environmental awareness and regulations have raised concerns about the potential generation of secondary contamination by adding treatment chemicals, including the added chemicals themselves and the secondary products of PAM. The reaction of advanced oxidation processes (AOPs), including chlorine, potassium permanganate and Fenton’s reagent with PAM in FPW may result in the formation of oxidation products with potentially adverse effects on human health, including acrylamide as a neurotoxin and potential carcinogen11,46.

Membrane filtrations are often used in water treatment for a wide range of pollutants. The commonly used membranes for the membrane treatment of FPW are depicted in Fig. 4. Among them, pressure-driven membranes suitable for high TDS conditions and low-pressure membranes utilized in mobile and on-site applications with limited space47,48,49. However, the PAM in FPW may cause membrane fouling, and the presence of wet hydrocarbons exacerbates the treatment challenges for most types of membranes25,47. Pre-filtration with membranes of appropriate pore sizes can effectively reduce the fouling index of PAM. Using approximately 0.1 L of synthetic reflux water, generated by incubating 1.5% PAM with 0.0001 g/L (0.0004 mM) ammonium persulfate without shale at 80 °C for 24 h, pre-filtration was conducted through different polycarbonate track-etched membranes with uniform pores of varying sizes25. The 0.2 μm membrane reduced the fouling index to 43 m−1, and the 0.1 μm membrane lowered the fouling index to 13 m−1 while the flux decline curves for 0.4 μm and 0.8 μm membranes closely resembled those of the unfiltered solution, with pollution indices ranging from 90 to 110 m−125. However, controlling fouling through pre-treatment with this type of membrane is challenging because the removal of most polymers may occur via severely fouled polycarbonate membranes, not necessarily by reducing the molecular weight of PAM.

Reprinted from Desalination, Vol 455, Chang et al., Potential and implemented membrane-based technologies for the treatment and reuse of flowback and produced water from shale gas and oil plays: A review, Pages 4047. Copyright 2019, with permission from Elsevier.

Biological treatments are often implemented to remove organic compounds50, and 86.64% of PAM was biodegraded by the microorganisms involved in the biological hydrolysis of PAM removal in waste-activated sludge fermentation systems under optimized conditions51. However, the complex chemistry such as salt and biocides in oil and gas development wastewater may inhibit the PAM degradation. Primarily, the increasing salt concentration results in a decline in the degradation rates of dissolved organic carbon (DOC), suggesting a decrease in overall biodegradation efficiency27. Additionally, the occurrence of undesirable by-products caused by microorganisms such as sulfate-reducing bacteria (SRB), which generates acetate and ammonium ions from the biodegradation of hydrolyzed HPAM, promoting the anodic dissolution of steel, resulting in an increased corrosion rate and localized perforation of carbon steel pipelines52,53.

Perspectives on future directions

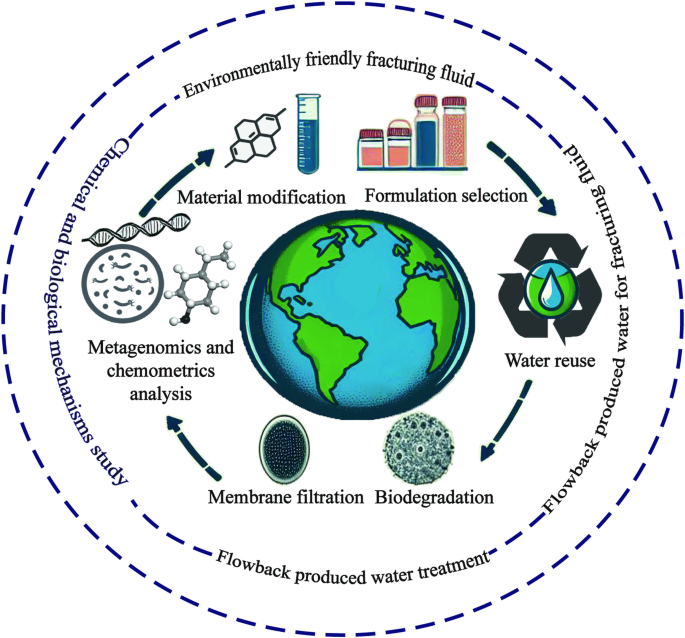

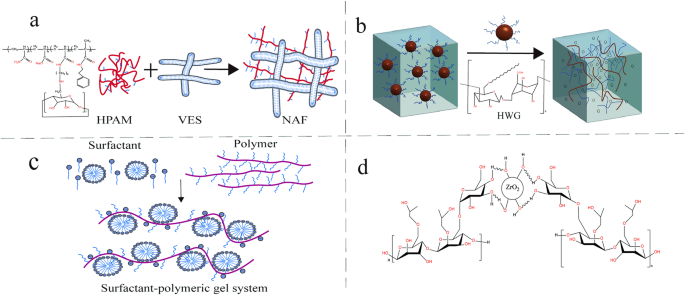

Including sustainability considerations in the use and management of PAM can enhance productivity and mitigate risks. We have put forth a conceptual cycle outlining the sustainable development of HF fluid (Fig. 5). Firstly, it is critical to consistently improve the overall functions of the PAM and its fluid systems and to reduce their residues. A composite gel named NAF was created by combining self-synthesized β-cyclodextrin-functionalized hydrophobically modified polyacrylamide (HMPAM) with a viscoelastic surfactant (VES) (Fig. 6a)19. NAF has substantially enhanced apparent viscosity and viscoelasticity than that of HMPAM or VES, and, importantly, the gel could be completely decomposed19. Introducing hydrophobic long-chain molecules to modify polymers promotes their extension in aqueous solutions, enhancing their resistance to enhanced temperature and salt54.

A concept of sustainable development of hydraulic fracturing fluid.

The conceptual sketches of (a) supramolecular complex of HMPAM and VES (b) 1‑Bromohexadecane-modified welan gum (c) surfactant-polymeric gel system (d) nano‐ZrO2 combined with HPG. The figure is modified from Pu et al., Wang et al., Das et al., and Chen et al.19,54,62,63.

Secondly, introducing alternative polymers in the preparation of HF fluids and other production working fluids may also simplify water treatment processes. Despite the challenges associated with treating PAM, it remains a commonly used substance. A primary reason for this is that natural materials cannot serve as a well-established substitute for PAM. Thermal resistance is a major obstacle for natural gums to replace PAM. To date, the reported highest temperature resistance of the natural gum is 150 °C13. Natural material and fluid system development and modification are promising, including modifying various gums, starch, and organic zirconium products54,55,56,57. These materials and fluid systems are either more environmentally friendly or more easily depolymerized.

Guar gum, being a natural material, demonstrates thickening, gelling, and binding properties, as well as a high biodegradability potential58,59. The activated sludge may biodegrade over 90% of the chemical oxygen demand (COD) of FPW, which contains guar gum, a principal ingredient, within 10 hours under typical flowback conditions60. Functional group modifications are introduced to guar gum to change its rheology and thermal and salt-resistance59. For example, hydroxypropyl guar gum (HPG) and carboxymethyl hydroxypropyl guar gum (CMHPG) are employed in conventional hydrocarbon development12,61. In addition to the well-established modification techniques for guar gum, such as those applied to natural materials, there are also novel modification approaches being explored for xanthan gum. Under NaOH catalysis, welan gum could be modified with 1-bromohexadecane, resulting in hydrophobically modified welan gum (HWG) (Fig. 6b)54. Compared to guar gum, HWG showed enhanced network formation and sustained molecular chain extension under mixed salt conditions (85,000 mg/L) and higher solution viscosity (225.58 mPa·s) than that for guar gum (110.34 mPa·s)54. Nevertheless, the elevated costs, constraints in proppant transport, and heightened challenges in biodegradation may impede the field application.

Thirdly, incorporating supplementary materials into the fluid system is beneficial, especially for enhancing the properties of natural and environmentally friendly polymers. A polymer gel system (carboxymethyl hydroxypropyl guar gum – CMHPG) has been innovatively combined with a surfactant-based viscoelastic fluid (sodium oleate-anionic surfactant) to create a novel-single phase microemulsion (SPME) gel (Fig. 6c)62. This mixed gel with intensive interactions between polymer and surfactant clusters exhibited enhanced rheological properties and thermal stability up to 120 °C and left negligible residue under low polymer concentrations62. Similarly, the stability and rheological property of the HPG could be mitigated by adding citric acid and Nano-ZrO2, respectively (Fig. 6d)56,63.

Fourthly, utilizing high-throughput sequencing to assist polymer selection; to explore and predict systematic changes in microbial communities under various polymer exposures, thus facilitating the innovations in green polymer utilization64. High-throughput sequencing and multiple omics enable an in-depth understanding of the structure, functionality, and intra- and extra-interactions of microbial communities65. Microbial community responses are important indicators for environmental impacts and thus coupling biological assessment of the chemical uses is aimed to minimize environmental risks in the first place66.

Nevertheless, increasingly complex modifications of polymers and/or fluid systems are often accompanied by increased costs for operators. The environmental impact of these modified materials compared to the original products is yet to be understood. Addressing these issues requires enhanced collaboration between regulators, production, and environmental sectors.

With regard to water treatment, operators prioritize technologies that are cost-effective and space-friendly (mobile). In specific Chinese production regions such as the Sichuan Basin and the Bohai Sea, integrated treatment systems have been adopted. Growing environmental awareness and carbon neutrality pressures have led to increasing attention on renewable treatment materials and technologies, such as biological treatment, adsorption, and filtration using green and recyclable materials.

Membrane treatment of PAM in FPW results in rapid fouling, and conventional water quality tests cannot predict the fouling potential of PAM due to the lack of correlation between PAM concentration and total organic carbon (TOC), total suspended solids (TSS), and turbidity, owing to the complex composition of FPW25,67. Using specific methods, such as the starch-cadmium iodide method, to monitor PAM content in FPW, and employing pre-treatment methods outside of membrane filtration, such as activated sludge, precipitation, and coagulation based on fouling type, can effectively mitigate membrane fouling processes, while also establishing efficient cleaning protocols and regular maintenance schedules to prevent fouling accumulation and ensure the long-term efficient operation of the membrane system25,67,68.

For biological treatment, the high salinity hinders microbial biodegradation of organic compounds, and diluting with water derived from the subsurface with salinity up to millions of ppm requires nonignorable freshwater resource69. Acclimatization of isolated microorganisms in adaptation to saline environment and enhance biodegradation efficiency is possible, and an alternative solution is genome mining of halotolerant microbes with sufficient PAM degradation potentials and synthesis of enzymes and other natural products to targeted degrade PAM in saline fluid. Additionally, multiple omics technologies facilitate the understanding of the involved organisms and their interrelationships to boost microbial activities in more extreme environments70.

Conclusions

The transition from conventional to unconventional hydrocarbon development, coupled with the shift from onshore to offshore hydrocarbon development, introduces additional complexities to the water treatment of polymers such as representative PAM. In alignment with an increasing commitment to sustainable practices and environmental awareness, there is a heightened emphasis on pre-evaluation and prediction of the environmental impacts of chemical uses, and researching innovative green polymers. Moreover, intensified attention is being directed toward advancing membrane and biological treatment technologies.

Crucial forthcoming steps involve researching products as substitutes to PAM with reduced environmental footprints. This includes developing new polymers, and fluid systems, and modifying existing natural polymers. Additionally, there is an exploration of saline-resistant microbes with robust biodegradation capabilities using cutting-edge techniques (e.g., genome mining), and developing anti-fouling membranes while optimizing membrane cleaning strategies. These initiatives underscore contemporary efforts to explore sustainable alternatives, aiming to manage polymers effectively throughout various stages of hydrocarbon development.

Responses